- Product Details

- {{item.text}}

Quick Details

-

Power:

-

15-70Kw Depends

-

Dimension(L*W*H):

-

User Requirements

-

Weight:

-

adjustable according to volume

-

Warranty:

-

3 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Insulation layer::

-

PU or rockwool

-

Thiskness::

-

2-4mm

-

Controlling way::

-

Simens PLC touch screen/Semi-auto

-

Heating way::

-

Steam/electric/direct fire heating

-

Cooling way::

-

Miller board or Ice water belt

-

Working pressure::

-

0.1-0.15Mpa

-

Plate surface::

-

Mirror, wire drawing, 2B

-

Fermenter cone::

-

60-75°

-

Cleaning system::

-

CIP cleaning tank/pump, CIP cleaning Ball

-

Certification:

-

CE;ISO9001-2008

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HBETBREW

-

Voltage:

-

3phase/380(220V)

-

Power:

-

15-70Kw Depends

-

Dimension(L*W*H):

-

User Requirements

-

Weight:

-

adjustable according to volume

-

Warranty:

-

3 Years

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Insulation layer::

-

PU or rockwool

-

Thiskness::

-

2-4mm

-

Controlling way::

-

Simens PLC touch screen/Semi-auto

-

Heating way::

-

Steam/electric/direct fire heating

-

Cooling way::

-

Miller board or Ice water belt

-

Working pressure::

-

0.1-0.15Mpa

-

Plate surface::

-

Mirror, wire drawing, 2B

-

Fermenter cone::

-

60-75°

-

Cleaning system::

-

CIP cleaning tank/pump, CIP cleaning Ball

-

Certification:

-

CE;ISO9001-2008

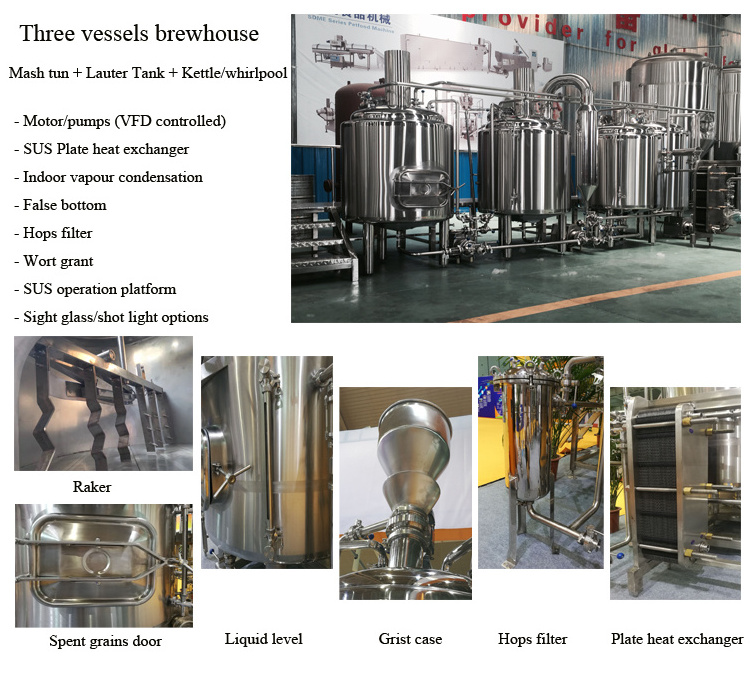

Commercial Beer Equipment Beer Brewing System

Brewhouse:

Regarding the brewhouse of beer brewing equipment, we have two vessels, three vessels and four vessels brewhouse for your choose.

Two vessels brewhouse detail information:

Mash tun:

Mashroom-shaped head or dish head on the top

80mm PU insulation

Agitator with VFD controlled

SUS or glass manhole

CIP cleaning device

Legs and other pipelines and valves

Lauter tank:

Mashroom-shaped head or dish head on the top

80mm PU insulation

Raker arm with speed controller

Side mounted grain outdoor with grain chute, size is 430*330mm

Easy clean and detachable sparging spray ring

Leaser cutting false bottom

SUS or glass manhole

CIP cleaning device

Legs and other pipelines and valves

Kettle/Whirlpool:

Mashroom-shaped head or dish head on the top

80mm PU insulation

Heating: electric, steam or direct fire heating

Tangential whirlpool inlet

SUS or glass manhole

CIP cleaning device

Legs and other pipelines and valves

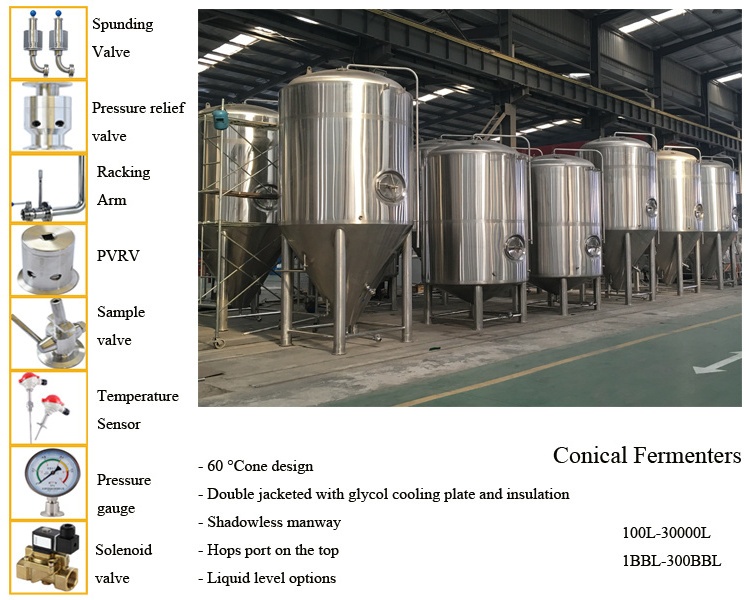

Fermenters:

|

No. |

Item |

Introduction |

|

01 |

Volume |

100L-50000L or even bigger |

|

02 |

Material |

Stainless steel 304 or 316 |

|

03 |

Insulation |

Polyurethane, TH: 80-100mm |

|

04 |

Fermentation tank |

|

|

05 |

Dish Head |

Double or single dish head on the top |

|

06 |

Accessories |

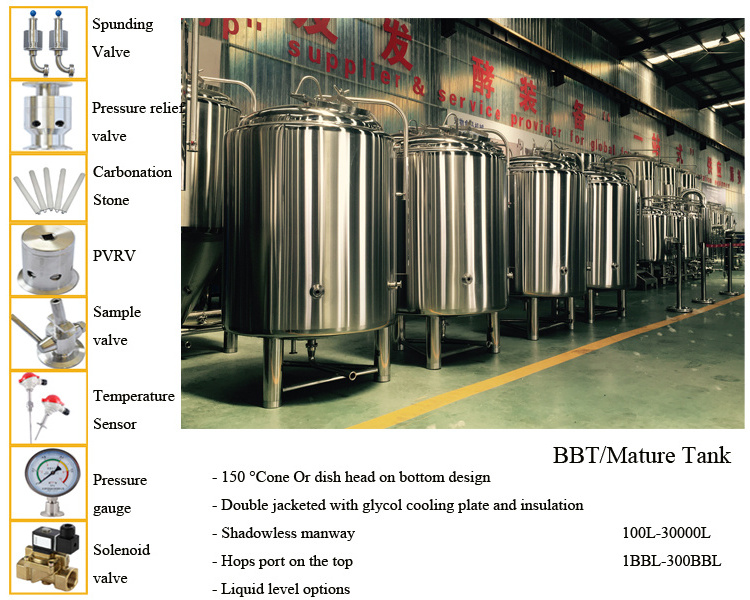

BBT:

|

01 |

Volume |

100L-50000L or even bigger |

|

02 |

Material |

Stainless steel 304 or 316 |

|

03 |

Insulation |

Polyurethane, TH: 80-100mm |

|

04 |

Fermentation tank |

|

|

05 |

Dish Head |

Double or single dish head on the top |

|

06 |

Accessories |

1. Free of charge the consultation service before, during, and after sales .

Your questions would be replied within 24 hours by our sales team.

2.There are professional engineers and technicians in our company, so we can customize the equipment, and we can provide beer production technology and brewing formula, equipment design, installation and debugging, and personnel training service;

3.Providing 3D and CAD layout drawing within 5working days after get buyer’s building plan.

4. Provide 5years complete warrantee for tanks body and life-time maintenance service; All of the accessories and auxuliaries facilities are guaranteed for one year; The seller is responsible for the nature damage of the machinery in the warranty period except for man-made damage. All spare parts and wearing parts are included with the brewery for free.

Hot products

Hot products

For small beer brewing equipment, 500L, 1000L, 2000L systems are more suitable. At present, these models of beer brewing equipment are the most popular and most sold products. Do you plan to build a micro beer brewery plant? Please send inquiry to us.

HBETBREW can supply you with the complete beer brewery equipment, it means that except the brewhouse and fermenters, we also can supply other brewery related equipment to you, such as malt miller, cleaning system, cooling system electrical control system, keg filler, keg washer and bottling machine.

Welcome to review more equipment for your brewery project.

In order to improve the production quality and production efficiency of beer brewing equipment, our company has introduced many advanced automated production equipment, such as laser cutting machine, circumferential seam welding machine, longitudinal seam welding machine, circumferential seam polishing machine, longitudinal seam polishing machine, automatic pipe welding machine. , punching machine, bending machine, etc., greatly providing production efficiency and product quality

In order to ensure the quality of our products, our company has introduced spectrometers, thickness gauges and roughness testers. Through these testing equipments, we strictly control the quality of raw materials, production and processing details of our products, and provide customers with professional high quality products. Welcome to visit us and inspect the equipment in person.