- Product Details

- {{item.text}}

Quick Details

-

Power:

-

2220

-

Dimension(L*W*H):

-

565*375*438mm

-

Weight:

-

40 kg, 40kg

-

Process Air Rated Airflow:

-

300m3/h

-

Process Air Process Motor Power:

-

0.16kW

-

Application:

-

Industrial use or commercial use

-

Capacity:

-

1.5kg/h(20°C,70%)

-

Reactivation Air Rated Airflow:

-

100m3/h

-

Reactivation Air React. Motor Power:

-

0.14kW

-

Drive Motor Motor Power:

-

0.025kW

-

Reactivation Mode Electric, Max Powe:

-

1.895kW

-

Supply power:

-

220V

Quick Details

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

FEISHI/OEM

-

Voltage:

-

220V

-

Power:

-

2220

-

Dimension(L*W*H):

-

565*375*438mm

-

Weight:

-

40 kg, 40kg

-

Process Air Rated Airflow:

-

300m3/h

-

Process Air Process Motor Power:

-

0.16kW

-

Application:

-

Industrial use or commercial use

-

Capacity:

-

1.5kg/h(20°C,70%)

-

Reactivation Air Rated Airflow:

-

100m3/h

-

Reactivation Air React. Motor Power:

-

0.14kW

-

Drive Motor Motor Power:

-

0.025kW

-

Reactivation Mode Electric, Max Powe:

-

1.895kW

-

Supply power:

-

220V

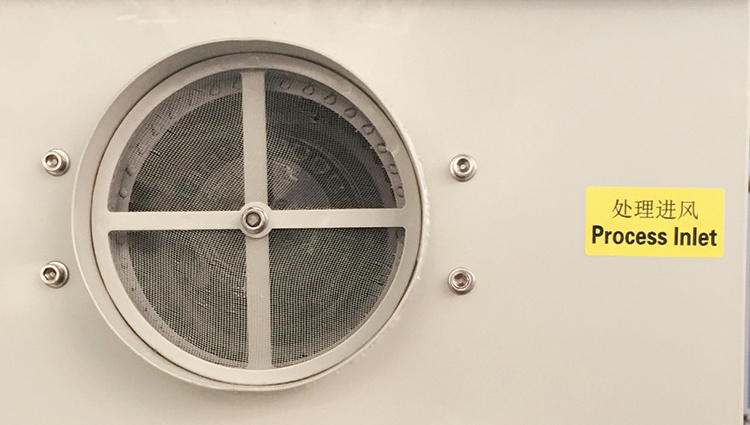

Rotor Desiccant Dehumidifier Manufacturer in China

Work Principle

The core component of rotary dehumidifier is the 8-16 hour spin in turn densely cellular Conde desiccant wheel.

The desiccant wheel on both sides by high-performance silicon fluorine rubber seals along the entire surface of the radial will be divided into 270 ° of the treatment area and 90 ° of the regeneration zone, when the moist air comes into the processing area, the air moisture in the desiccant wheel was absorbed into dry air, dry air meet the need of dry place or gas production process.

Specifications

|

Main Parameters/Model |

ZLMD-1 |

ZLMD-2 |

|

|

Process Air |

Rated Airflow(m 3 /h) |

150 |

300 |

|

Process Motor Power (kW) |

0.113 |

0.16 |

|

|

Process ESP(Pa) |

/ |

/ |

|

|

Reactivation Air |

Rated Airflow(m 3 /h) |

66 |

100 |

|

React. Motor Power (kW) |

0.078 |

0.14 |

|

|

Process ESP(Pa) |

/ |

/ |

|

|

Drive Motor |

Motor Power (kW) |

0.015 |

0.025 |

|

Reactivation Mode |

Electric, Max Power (kW) |

1 |

1.895 |

|

Steam Pressure (Mpa) |

0.35~0.45 |

||

|

Steam Consumption(kg/h) |

/ |

/ |

|

|

Dehumidifying Capacity (20°C,70%) (kg/h) |

1 |

1.5 |

|

|

Total Rated Power (kW) |

Electric Heating Mode |

1.206 |

2.22 |

|

Steam Heating Mode |

/ |

/ |

|

|

Size (mm) |

Length |

525 |

565 |

|

Width |

372 |

375 |

|

|

Height |

382 |

438 |

|

|

Approx. Weight (kg) |

30 |

40 |

|

|

Supply Power |

1ph,220V/50Hz |

||

|

Latent heat temperature rise (kW/h) |

0.9~1.1 |

1.8~2.2 |

|

1. Main components: pre-filter, desiccant rotor, process fan, electric controller and cabinet.

2. The cabinet is made of aluminum alloy, and double insulation panel structure with high density polyurethane insulation material inside, strong, compact, anti-corrosion, and it is anti-“cold bridge” which can help avoid condensation.

3. The dehumidifier select silica gel desiccant wheel.

4. Select centrifugal fan, its impeller and vent was plated with anti-corrosion coating, it’s strong and anti-corrosion.

5. G4 rough effect air filters to assure air purity.

6. Use text display, temperature and humidity probe to control temperature and humidity. It is convenient to operate.