- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380V/50HZ

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

2380*1370*1690mm

-

Weight (KG):

-

200

-

Marketing Type:

-

Hot Product 2023

-

capacity:

-

100000kcal/h to 4000000kcal/h

-

temnpearture:

-

50-350 degree C

-

Fuel:

-

diesel, gas, oil, natural gas, hfo, fuel oil, waste oil

-

Weight:

-

40000KG

Quick Details

-

Type:

-

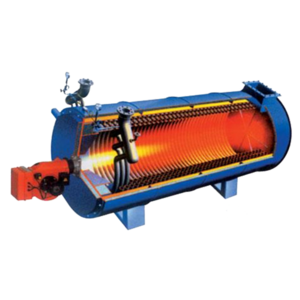

Hot Air Furnace

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TAIGUO

-

Voltage:

-

380V/50HZ

-

Power:

-

7.5kw

-

Dimension(L*W*H):

-

2380*1370*1690mm

-

Weight (KG):

-

200

-

Marketing Type:

-

Hot Product 2023

-

capacity:

-

100000kcal/h to 4000000kcal/h

-

temnpearture:

-

50-350 degree C

-

Fuel:

-

diesel, gas, oil, natural gas, hfo, fuel oil, waste oil

-

Weight:

-

40000KG

200000kcal 300000kcal 60000kcal 1000000kcal gas oil diesel fired hot air generator for baking /drying/dyeing / chemical industry

Hot air Generator / Hot Air Heater/ Hot Air Furnace /hot air dryer/hot air stove

1. Provide hot air for drying, heating, melting, reacting;

2. High heat efficiency, convenient installing, energy saving, Eco-friendly.

3. it is widely used in the industries of chemistry, building materials, ceramics, metallurgy, feedstuff, fertilizer and so on,

4. There is no influence on whiteness and purity of product.

5.The hot air temperature can be adjustable easily.

6.It is easy to operate and maintain.

Gas oil diesel fired hot air generator for baking /drying/dyeing / chemical industry Application :

1. Widely used in food, medicinal materials, all kinds of agricultural and sideline products and

2.All kinds of material drying, printing and dyeing, paint dry heat source, Can also be used for heating of tall building

3.plastic greenhouses and dehumidification of underground mines, underground engineering and so on need of drying.

especially suitable for metallurgy, chemical industry,ceramics production, forage, feed and other industrie s.

Gas oil diesel fired hot air generator for baking /drying/dyeing / chemical industry Product feature:

1.Fuel: gas or oil, coal or Biomass

2.As clean air as medium,no pollution

3.Low energy consumption and high thermal efficiency

4.Automatically test temperature and display

5.usage:chemical-industry,food,medicinal-materials ,tobacco,ceramics,building materials as so on to dry ,and spray ,dehydration ,to heat in the

factory ,assembly hall,agriculture tent ,animal house .

| Model | LRF-20 | LRF-30 | LRF-40 | LRF-60 |

LRF-80 |

LRF-100 | LRF-120 | WRF-160 | WRF-200 | WRF-250 | WRF-400 |

| Rated heat supply(104kcal/h) | 20 | 30 | 40 | 60 | 80 | 100 | 120 | 160 | 200 | 250 | 400 |

| Using temperature(℃) | 150~500 | ||||||||||

| Work medium | Air | ||||||||||

| Design fuel | Bituminous coals,light diesel,liquefied natural gas | ||||||||||

| Thermal efficiency(%) | 85 | ||||||||||

| Coal consumption(kg/h) | 32 | 45 | 65 | 98 | 120 | 150 | 180 | 256 | 360 | 420 | 180 |

Part F: The overview of our company

- Worker number:about 800, senior engineer:5 Intermediate Engineers: 35 junior engineer: 15, technical man:280

- Factory area:20000 square meter, building area: 80000 square meter

- We have strong study team, the most famous study institute in China are worked with us.

- The production equipment: more of 350 units, production capacity: 6000t/h boiler per year and pressure vessel 1800 units

FAQ1: How can you get the best price quickly?

Answer :

As soon as the steam capacity and pressure are told, we will make the detail price list at once.

FAQ2: Why should you believe our quality ?

Answer :

- 38 year experience, founed since 1976; Chinese-government appointed Grade A Boiler Manufacturer.

- With BV, ISO9001, CE certificates.

- Quality control system: Include 8 subsystems , design, techonics, welding, inspection, non-destructive testing, heat treatment, materials physics and chemistry inspection, device management Each process will be strict supervised. 5 process quality point, R aw material inspection, product specimen, NDT, hydrostatic test, Heat treatment . The products must be inspected by third party before delivery.

FAQ3: What about the installation?

Answer :

When you receive the boiler, we will guide you to make some preparation for installation; after that, our expert will fly to your local place in 72 hours. The experts will responsible for guiding installation,training, trial operation.