- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

ABP

-

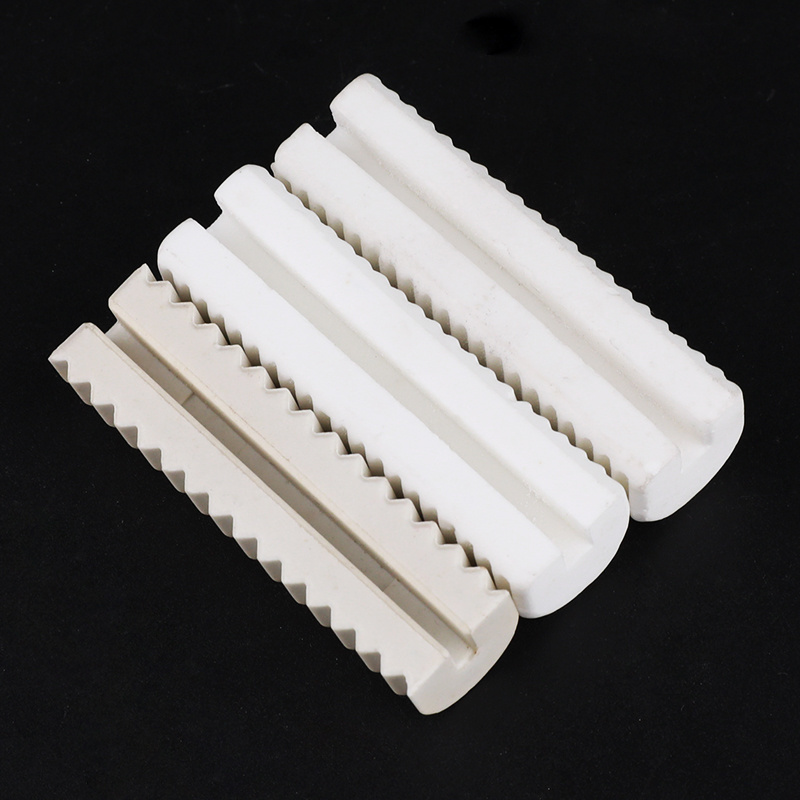

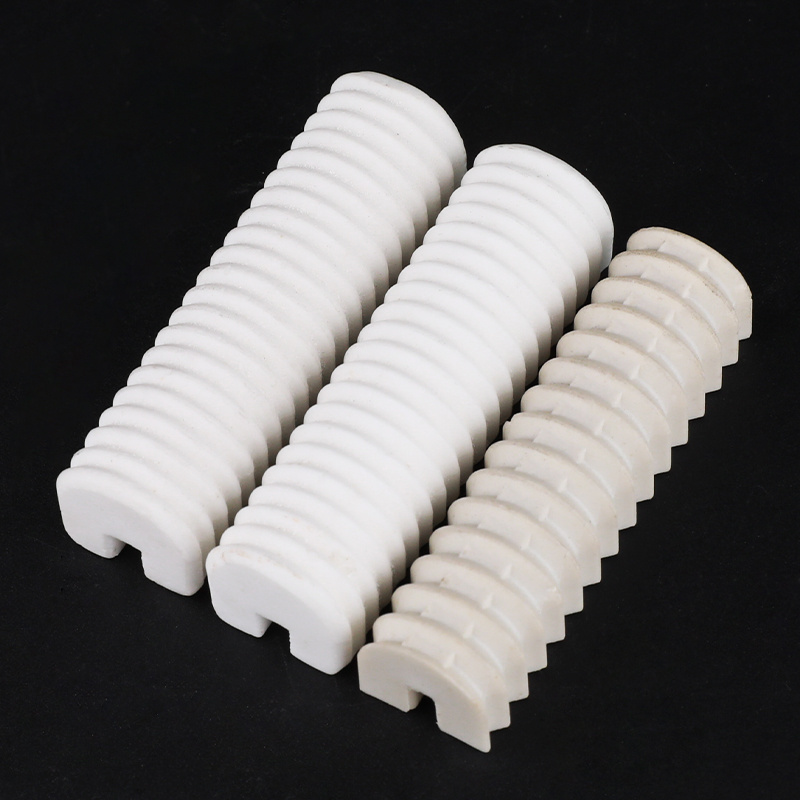

Product name:

-

Alumina Ceramic Part

Quick Details

-

Material:

-

Alumina Ceramic

-

Place of Origin:

-

Jiangsu, China

-

Model Number:

-

0159

-

Brand Name:

-

ABP

-

Product name:

-

Alumina Ceramic Part

Product Paramenters

|

Table of characteristics of refined ceramics

|

|

|

|

|

||||

|

|

Name

|

99 porcelain

|

95 porcelain

|

Zirconia

|

||||

|

|

Main ingredients

|

Al₂O₃≥99%

|

Al₂O₃≥95%

|

ZrO₂≥94%

|

||||

|

Physical

properties

|

Density

|

3.85

|

3.6

|

5.9

|

||||

|

|

Water Absorption %

|

0

|

0

|

0

|

||||

|

|

Sintering temperature °C

|

1690

|

1670

|

1650

|

||||

|

Quality characteristics |

Hardness HV

|

1700

|

1600

|

1400

|

||||

|

|

Flexural strength 4pt

|

>3500

|

>2900

|

>11000

|

||||

|

|

Compressive strength /cm²

|

30000

|

25000

|

25000

|

||||

|

Thermodynamicproperties |

Maximum service temperature °C

|

1500

|

1400

|

1600

|

||||

|

|

Coefficient of thermal expansion

|

8

|

7.8

|

10

|

||||

|

|

10-6/°C

|

|

|

|

||||

|

|

0-1000°C

|

|

|

|

||||

|

|

Heat shock resistance (°C)

|

200

|

220

|

350

|

||||

|

|

Thermal conductivity W/m.k

|

31

|

22

|

3

|

||||

|

Electrical

characteristics

|

Volume resistivity Ω.cm

|

>10

12

|

>10

12

|

>10

12

|

||||

|

|

Breaking strength of insulation KT/m

|

18

|

16

|

15

|

||||

|

|

Dielectric constant 1MHZ(E)

|

9.2-10.5

|

9.0-10

|

12.5

|

||||

Products Description

Feature 01:Withstand high temperatures

Featuring high melting and boiling points, it can be used at high temperatures without being affected

.

Feature 02: Not easily corroded

It has the characteristics of high melting point and boiling point, and can be used at high temperatures without being affected, regardless of conditions such as strong acids, alkalis, inorganic or organic salts

.

Feature 03: Anti magnetic

Due to the non magnetic nature of the product material, it does not absorb dust and can reduce surface peeling

.

Feature 04: Electrical insulation

At room temperature, it is an insulator with high resistivity and can be used in equipment that requires insulation

.

Manufacturing Technique

01

Dry compression molding

02

Hot Die casting molding

03

Dewaxing at medium temperature

04

High-temperature firing

05

Centerless grinding

06

Inner circle grinding

07

Cylindrical grinding

08

Plane lapping

09

Internal control grinding and polishing

Application scope

01

Electrical industry

02

Electrical heating industry

03

Electronics

04

The automobile industry

05

Petrochemical industry

06

The textile industry

07

Lighting industry

08

Metallurgical industry

09

The medical industry

Factory Display

Service flow

This product is custom-made products, prices will fluctuate depending on product conditions, must contact customer service before placing an order! ! !

01

Provide requirements and drawings

02

Quotation and production cycle

03

Arrange the proofing

04

Confirm the sample

05

Normal production

06

Product delivery

Certificate

Recommend Products

FAQ

Q: Are you a trading company or a manufacturer?

A:

Our ceramic company was founded in 1993. After more than 30 years of joint efforts by all employees, our product quality, reputation, and service have received unanimous evaluations from domestic and foreign users. We have also passed the ISO9001:2000 quality management system certification.

A:

If the goods are in stock, it usually takes 5-10 days. If there is no stock, the delivery time will be agreed based on the quantity and requirements.

Q: Do you provide samples? Is it free or extra?

A:

Yes, we can provide samples for free, but you need to pay for the mold fee and shipping cost.

Q: How can you get a quote?

A:

Please send me your drawings along with the technical requirements and required quantity. If you do not have the drawings, please send us the samples by express delivery. We will quote the most favorable price as soon as possible.

Q: What are the possible shipping costs and packages?

A:

Packaging usually includes bubble packaging, cardboard boxes, pallets, cardboard boxes, etc. The transportation methods include express delivery, air freight, and sea freight. Both of us can negotiate and choose the best way.

Q: What are your payment terms?

A:

Payment<=1000 USD, 100% USD prepaid. Payment>=1000 US dollars, first pay the mold fee, after the sample is satisfactory, pay 50% of the advance fee, and pay the remaining 50% before delivery. The payment method is T/T.

Hot Searches