Explore More Products

- Product Details

- {{item.text}}

Quick Details

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

Shanghai

-

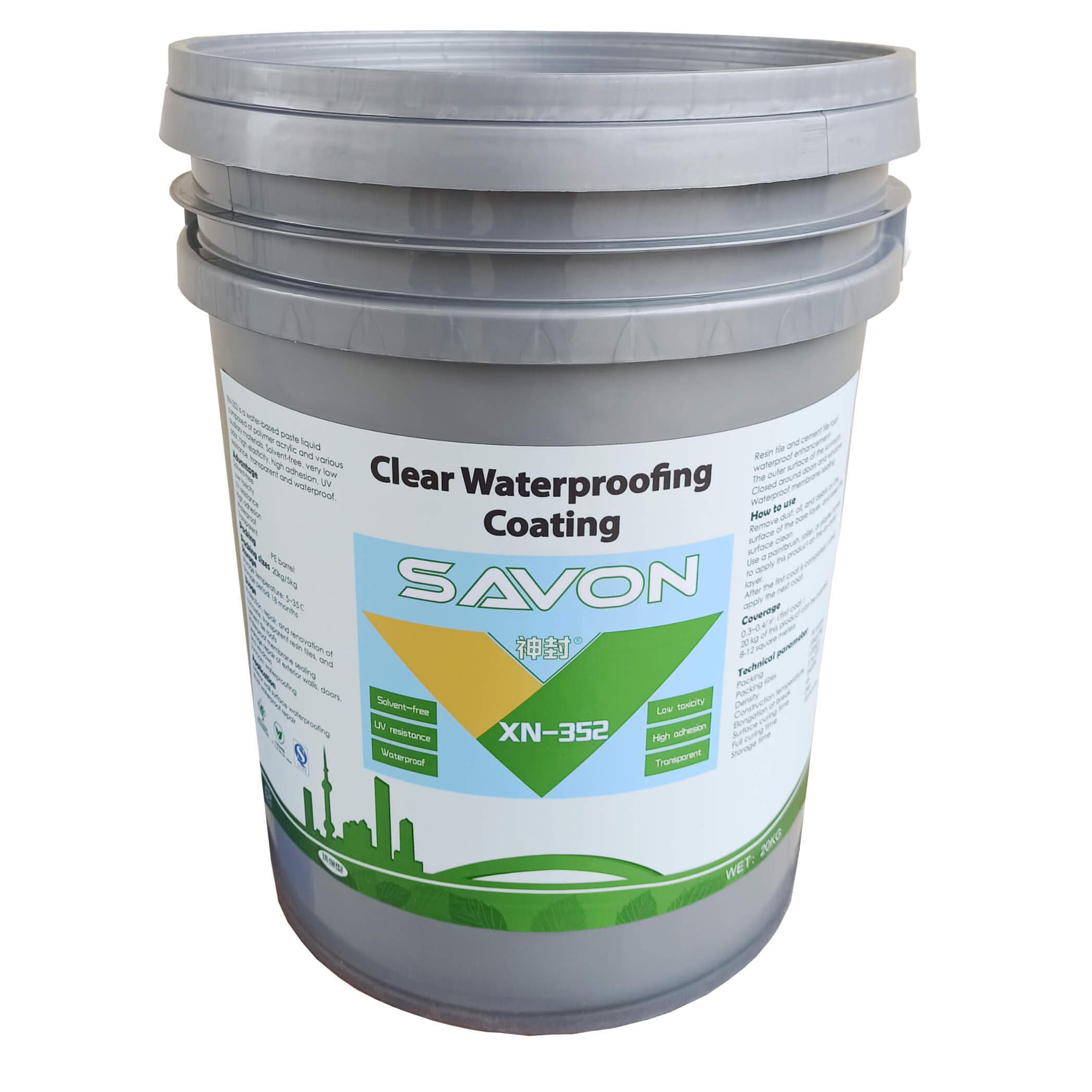

Brand Name:

-

SAVON

-

Model Number:

-

XN-352

-

Type:

-

Liquid

-

Product name:

-

Transparent Waterproof Sealant

-

Material:

-

Acrylic

-

Appearance:

-

Milky white viscous liquid

-

Finish color:

-

Clear

-

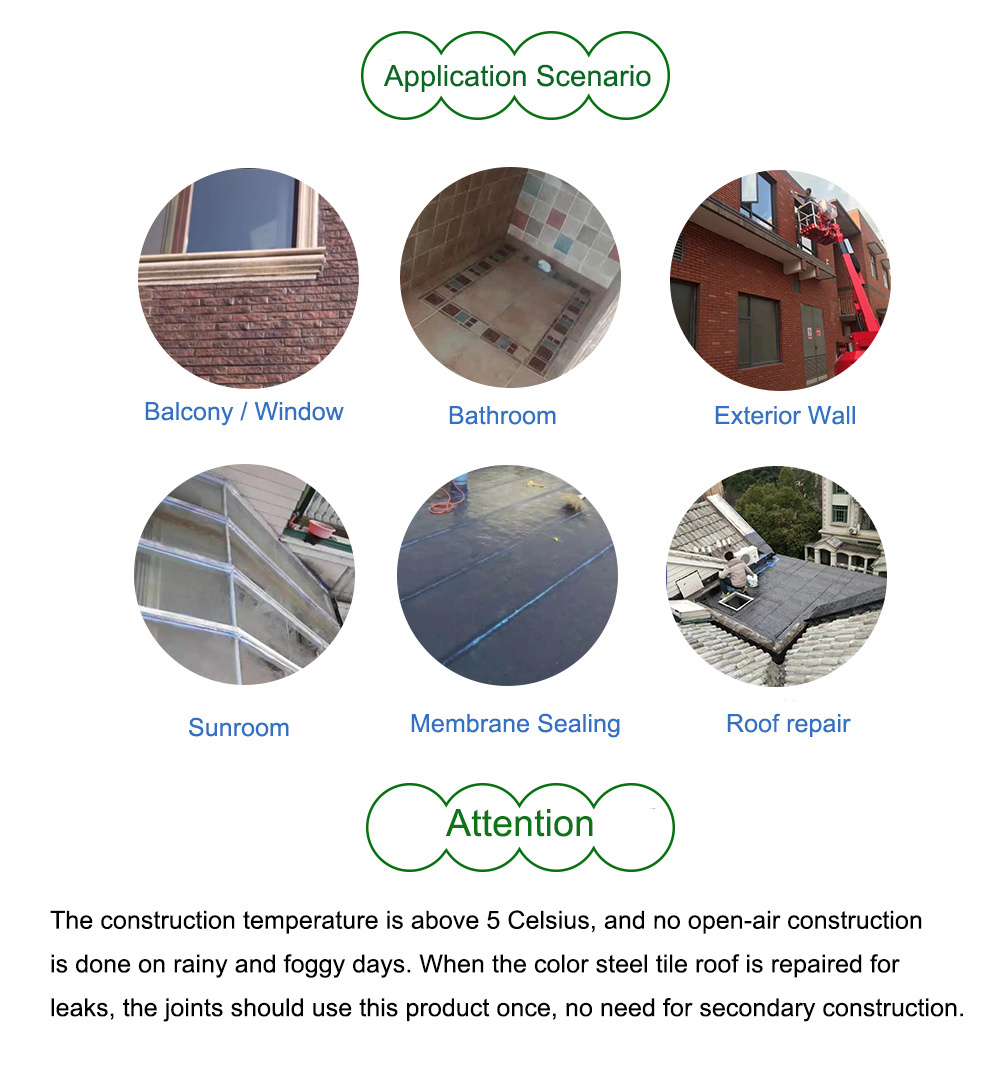

Application:

-

Spray, brush, roller

-

Packing:

-

5, 10, 20kg/barrel

-

Feature:

-

Waterproof, transparent, non-toxic

-

Certificate:

-

MSDS

-

Shelf life:

-

12 months

-

Keywords:

-

Waterproof Sealant

Quick Details

-

CAS No.:

-

79-10-7

-

Other Names:

-

Acroleic acid

-

MF:

-

C3H4O2

-

EINECS No.:

-

201-177-9

-

Place of Origin:

-

Shanghai

-

Brand Name:

-

SAVON

-

Model Number:

-

XN-352

-

Type:

-

Liquid

-

Product name:

-

Transparent Waterproof Sealant

-

Material:

-

Acrylic

-

Appearance:

-

Milky white viscous liquid

-

Finish color:

-

Clear

-

Application:

-

Spray, brush, roller

-

Packing:

-

5, 10, 20kg/barrel

-

Feature:

-

Waterproof, transparent, non-toxic

-

Certificate:

-

MSDS

-

Shelf life:

-

12 months

-

Keywords:

-

Waterproof Sealant

High-Quality Customized Acrylic Waterproof Paint for Fish Tanks Transparent Waterproof Sealant

| Item | Standard Values | Testing Result |

| Dry film appearance | Colorless and transparent | Colorless and transparent |

| Tensile strength,MPa | ≥1.0 | 2.5 |

| Elongation at break,(%) | ≥300 | 400 |

| Imperviousness(0.3MPa,0.5h) | Imperviousness | Imperviousness |

|

Surface drying time(h) Actually drying time(h) |

<4 ≤8 |

<4 <4 |

Pure acrylic waterproof sealant is a transparent and environmentally friendly building waterproofing material made from polymer synthesized polymers and high-quality functional waterproofing accessories.

Features:

1. Strong adhesion and no detachment.

2. Colorless and transparent, without affecting the original color.

3. The coating is waterproof, mold-resistant, and stain resistant.

4. Water-based and environmentally friendly.

1. Clean the base surface and repair the defects flat.

2. Use a paintbrush or roller to directly apply this product to the base surface, usually no less than twice, or use a screwdriver to scrape the construction.

3. If the base layer is a porous material, this product can be diluted with 20% clean water during the initial application. The previous coating film should be dried before applying the latter, with an interval of no less than 3 hours between the two coats.