- Product Details

- {{item.text}}

Quick Details

-

Power:

-

12kw

-

Dimension(L*W*H):

-

5360 *1700 *2280mm

-

Weight:

-

2100 kg

-

Product name:

-

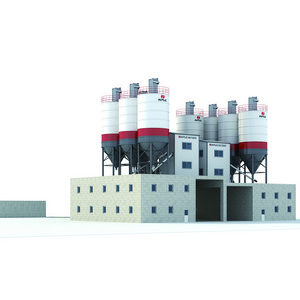

Concrete Batching Plant

-

Keyword:

-

Cost Concrete Batching Plant

-

Capacity:

-

Customized

-

Type:

-

Building Construction Tools

-

Application:

-

Construction Projects

-

Model:

-

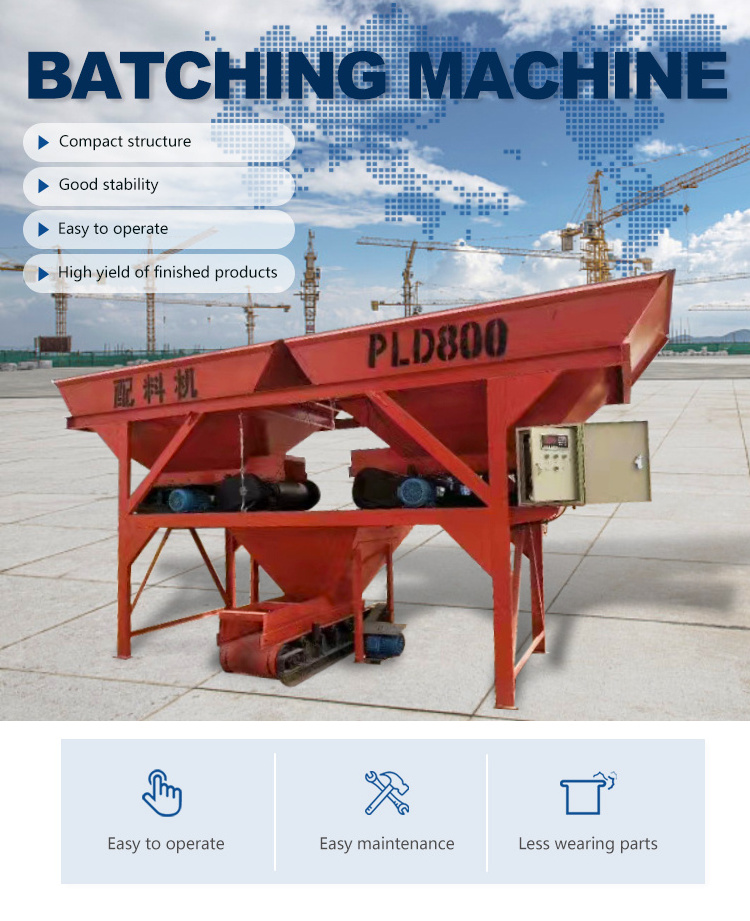

PLD800 Aggregate Batcher

-

Usage:

-

Producing Concrete

-

Color:

-

Customers' Request

-

Advantage:

-

High Efficiency Low Cost

Quick Details

-

Machine Type:

-

Batching machine

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HY

-

Power:

-

12kw

-

Dimension(L*W*H):

-

5360 *1700 *2280mm

-

Weight:

-

2100 kg

-

Product name:

-

Concrete Batching Plant

-

Keyword:

-

Cost Concrete Batching Plant

-

Capacity:

-

Customized

-

Type:

-

Building Construction Tools

-

Application:

-

Construction Projects

-

Model:

-

PLD800 Aggregate Batcher

-

Usage:

-

Producing Concrete

-

Color:

-

Customers' Request

-

Advantage:

-

High Efficiency Low Cost

Product Paramenters

|

Type

|

PLD800

|

PLD1200

|

PLD1600

|

PLD2400

|

PLD3200

|

PLD4800

|

|

Weighing bucket volume (m³)

|

0.8

|

1.2

|

1.6

|

2.4

|

3.2

|

4.8

|

|

Storage hopper volume (m³)

|

2x2

|

3x2.2

|

3x3.7

|

3x12

|

3x20

|

4x25

|

|

Productivity (m³/h)

|

48

|

60

|

80

|

120

|

160

|

280

|

|

Batching accuracy (%)

|

±2%

|

±2%

|

±2%

|

±2%

|

±2%

|

±2%

|

|

Maximum weighing value (kg)

|

1500

|

2000

|

3000

|

4000

|

5000

|

8000

|

|

Aggregate types available

|

2

|

2

|

3

|

3

|

3

|

4

|

|

Loading height (mm)

|

3000

|

3000

|

3000

|

3200

|

3500

|

3800

|

|

Belt speed (m/s))

|

1.25

|

1.25

|

1.25

|

1.0

|

1.0

|

1.0

|

|

Power (kW)

|

3×3

|

3×3

|

3×3+4×1

|

11

|

11

|

15

|

|

Total machine weight (kg)

|

2300

|

2300

|

4750

|

8500

|

10200

|

13600

|

|

Overall dimension (mm)

|

6000x1800 x3050 |

6000x2000x 3100 |

9000x2200 x3200 |

9800x2840 x3900 |

10140x2900 x4450 |

15520x3900 x5090 |

Product Introduction

Product Introduction

Before the work, the loader (when the doser is installed underground, it can be loaded manually) will supply sand and stone materials to each storage hopper respectively.

Input the recipe to the dosage controller according to the instructions of the dosage controller (the material not used must be set to 0). After pressing the dosage button, the dosage machine will start to enter the automatic dosage procedure. Its working process is as follows: firstly, the material Ⅰ belt machine starts to work, conveying the material Ⅰ to the weighing hopper, when the weight of the material Ⅰ in the weighing hopper reaches its set value, the material Ⅰ belt machine stops automatically; then the material Ⅱ belt machine opens automatically, when the weight of the material in the weighing hopper reaches the sum of the set value of the material Ⅰ and the material Ⅱ, the material Ⅱ belt machine stops and the material Ⅲ belt machine starts to work... ..., so that after the four kinds of materials are matched, the machine is in a waiting state. At this time, press the discharge button, the discharge belt machine work, will be matched with the dry concrete material into the mixer hopper. When the discharge is finished, the discharge belt stops automatically and the second cycle of batching starts automatically.

Sample Display

Other Equipment

Fully automatic steel cage machine

Batching Machine

Blender Production Site

Hot Searches