Adopt plc control system, the equipment operating parameters can be set on the display screen, easy to operate, and the data is easy to store.

- Product Details

- {{item.text}}

Quick Details

-

Production Speed(Cycles/min):

-

3-7

-

Air Pressure(MPa):

-

0.6 MPa

-

Sheet Thickness(mm):

-

0.2 - 2 mm

-

Heating Power (kW):

-

36 kW

-

Air Comsumption(L/min):

-

60 L/min

-

Water Comsumption(L/min):

-

3 L/min

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

no

-

Voltage:

-

380V 50HZ

-

Weight (T):

-

3 T

-

Power(KW):

-

36

-

After-sales Service Provided:

-

Online Support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Material:

-

PET PLA PS PP PVC

-

Color:

-

Customer Request

-

Finished Products:

-

Lunch Food Box

-

Model:

-

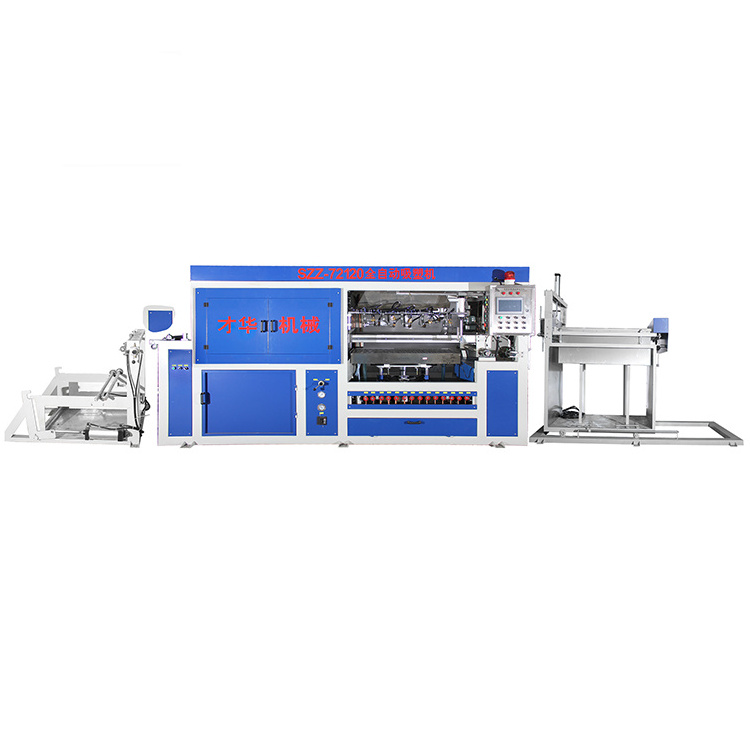

SZZ-72120

-

Material type:

-

plastic roll

-

Type:

-

Fully Automatic

-

Capacity:

-

30-50 Pcs/min

-

Power supply:

-

3 Phase 380V 50HZ

-

Material Thickness:

-

0.2-2mm

Quick Details

-

Max.Forming Height(mm):

-

180 mm

-

Forming Width (mm):

-

720 mm

-

Forming Length (mm):

-

1200 mm

-

Production Speed(Cycles/min):

-

3-7

-

Air Pressure(MPa):

-

0.6 MPa

-

Sheet Thickness(mm):

-

0.2 - 2 mm

-

Heating Power (kW):

-

36 kW

-

Air Comsumption(L/min):

-

60 L/min

-

Water Comsumption(L/min):

-

3 L/min

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

no

-

Voltage:

-

380V 50HZ

-

Weight (T):

-

3 T

-

Power(KW):

-

36

-

After-sales Service Provided:

-

Online Support, Video technical support, Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Online support

-

Material:

-

PET PLA PS PP PVC

-

Color:

-

Customer Request

-

Finished Products:

-

Lunch Food Box

-

Model:

-

SZZ-72120

-

Material type:

-

plastic roll

-

Type:

-

Fully Automatic

-

Capacity:

-

30-50 Pcs/min

-

Power supply:

-

3 Phase 380V 50HZ

-

Material Thickness:

-

0.2-2mm

Products Description

|

Model

|

Forming length

|

Forming width

|

Forming height

|

Machine weight

|

Overall size

|

|

SZZ-72120

|

650 ~ 1200mm

|

360 ~ 720mm

|

180mm

|

3T

|

7500 * 1400* 2400mm

|

|

Machine Main Specification

|

|

Machine Main Part

|

|

||

|

Model

|

SZZ-72120

|

Vacuum Pump

|

Germany Becker(100)

|

||

|

Voltage

|

380V 3P 50/60Hz

|

Relay

|

Japan IDEC

|

||

|

Power

|

30KW

|

Circuit Breaker

|

DELIXI(3P 100A)

|

||

|

Max Forming Size

|

720*1200MM

|

PLC

|

Delta (DVP32ES2)

|

||

|

Max Forming Height

|

200MM

|

Encoder Coder

|

Korea HRO

|

||

|

Production Speed

|

220-480Moulds/H

|

Nozzle

|

Taiwan 7-UP

|

||

|

Material Thickness

|

0.1-2MM

|

Magnetic Valve

|

Taiwan AIRTAC

|

||

|

Machine Dimension

|

7200*1700*2600MM

|

Air System

|

SNS

|

||

|

Machine Net Weight

|

3200KG

|

Touch Screen

|

MCGS

|

||

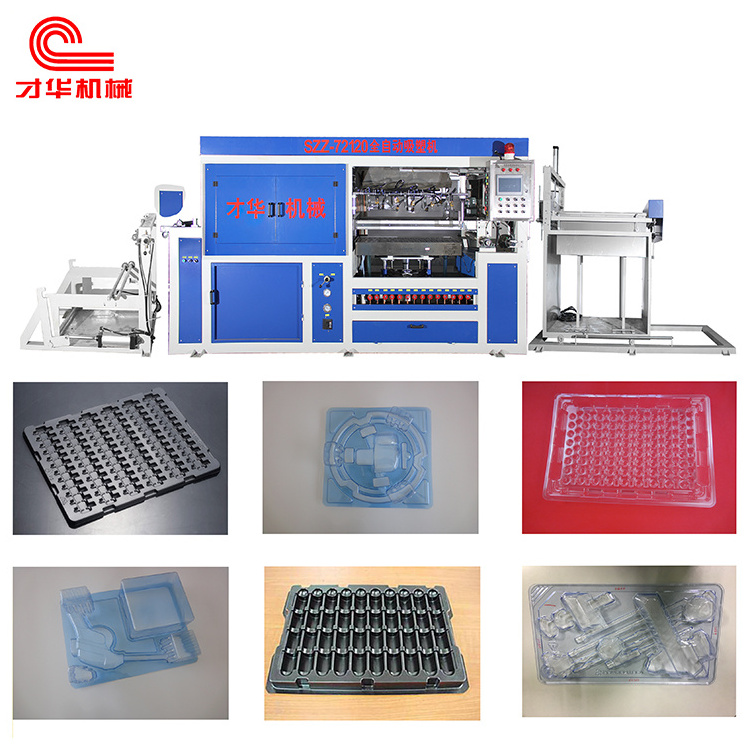

Application

Suitable for PVC, PE, PET, PETG, PP, PC, PS, HIPS, APET etc, the machine furnace produce heat to soften the plastic sheet, then vacuum pump sucks the plastic sheet down to the forming mould area to finish the forming, different forming mould enable to have different forming shape .

Full automatic vacuum forming plastic egg tray making machine.

It's suitable for the blister packaging in toys, hardware, food, electronic products, medicine, commodity, etc.

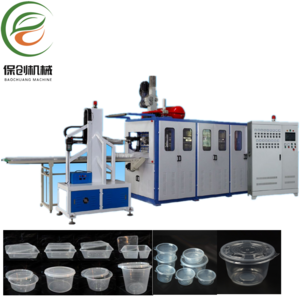

Full automatic disposable plastic food container vacuum forming machine.

Main Features

1. Motor puller and inverter speed control, encoder controls puller length, automatic brake circuit, high puller precision, and maximum puller error does not exceed 1mm

2. Independent and precise temperature control: using far-infrared ceramic heating plate for heating, the temperature of each heating plate can be set and controlled separately, and the set temperature value and actual temperature value are directly displayed on the screen in digital form, and any A heating plate is turned off, which is more suitable for producing complex products.

3.Complete functions: there are multiple functions such as secondary upper mold, secondary vacuum, and vibration demolding, which are more suitable for producing difficult products.

4. Equipped with chiller, cold water nozzle and wide-mouth fan, which can ensure good cooling of the product, fast molding speed and high production efficiency.

5. Aluminum alloy chain guide, light weight, high strength, no deformation, no corrosion.

Details Images

PLC CONTROL SYSTEM

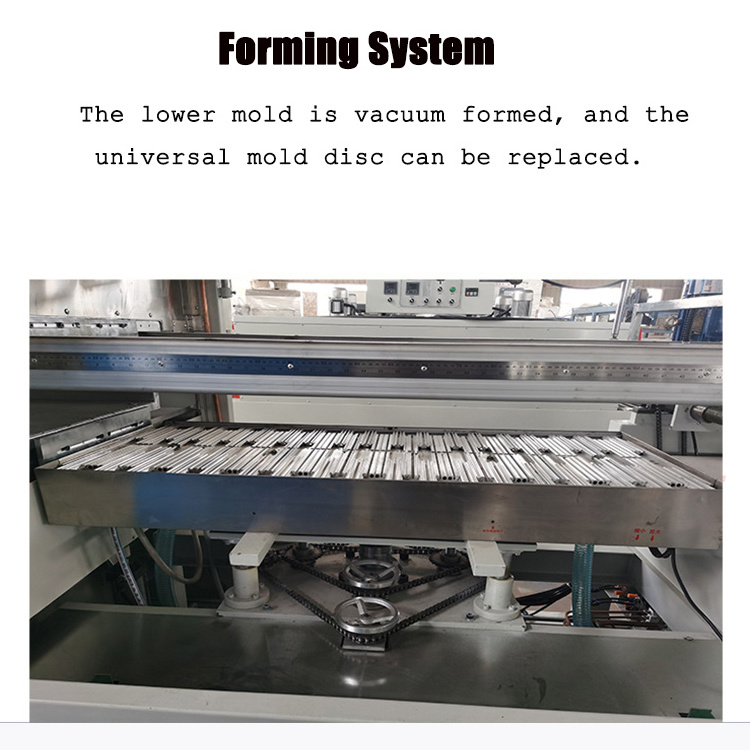

Forming system

The lower mold is vacuum formed, and the lower mold is equipped with a synchronous balancer to ensure the stable operation of the mold frame.

The lower mold is vacuum formed, and the lower mold is equipped with a synchronous balancer to ensure the stable operation of the mold frame.

Temperature control system

The heating furnace uses far-infrared ceramic heating, and the temperature control is one-to-one, which makes the temperature in the furnace area more uniform.

Sample

Customer Feedback

Packing&Livery

!!!This device does not need to be packed in a wooden box, and the entire container is shipped.

PACKAGE:

S

tandard export wooden case packing. Machine packing inside is plastic films and outside is fumigation wooden case. Our wooden case is very strong,it can bear long time shipping on the sea. And machine with preservative film, it can stop the salt sea water enter into the machine and make the machine corrosion.

DELIVERY TIME: 3-30 days after confirming order,detail delivery date should be decided according to production season and order quantity.

For machines are big and heavy parcel, and different country with different delivery cost,So we suggest below delivery solution:

For machine is big and heavy parcel, and different country with different delivery cost. And the best delivery we suggest is by sea, so the delivery cost will be depended on your destination port. The price show on the website just the machine EXW price,please understand.

Related Product

Hot Searches