- Product Details

- {{item.text}}

Quick Details

-

Center Height (mm):

-

50 mm

-

Max.Transformer Capacity(kVA):

-

30 kVA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

UnionSpring

-

Motor Power (kw):

-

3

-

Weight (KG):

-

900

-

Dimension(L*W*H):

-

1700*1250*2000

-

Wire Diameter Range (mm):

-

1 - 5 mm

-

Keyword:

-

copper coil forming machine

-

Function:

-

Automatic Winding/ forming

-

Application:

-

Winding/forming core

-

Winding machine Type:

-

Bobbin Winding Machine

-

Accept coil type:

-

copper round/flat wire

-

Wire Diameter:

-

1.0mm~5.0mm

-

Axis:

-

6 pcs

-

Wire Feeding Range:

-

0.1+N+1

-

Cable High:

-

≤60mm

-

Free Axis Max. Work Length:

-

≤70mm

Quick Details

-

Max. Load (KG):

-

750 KG

-

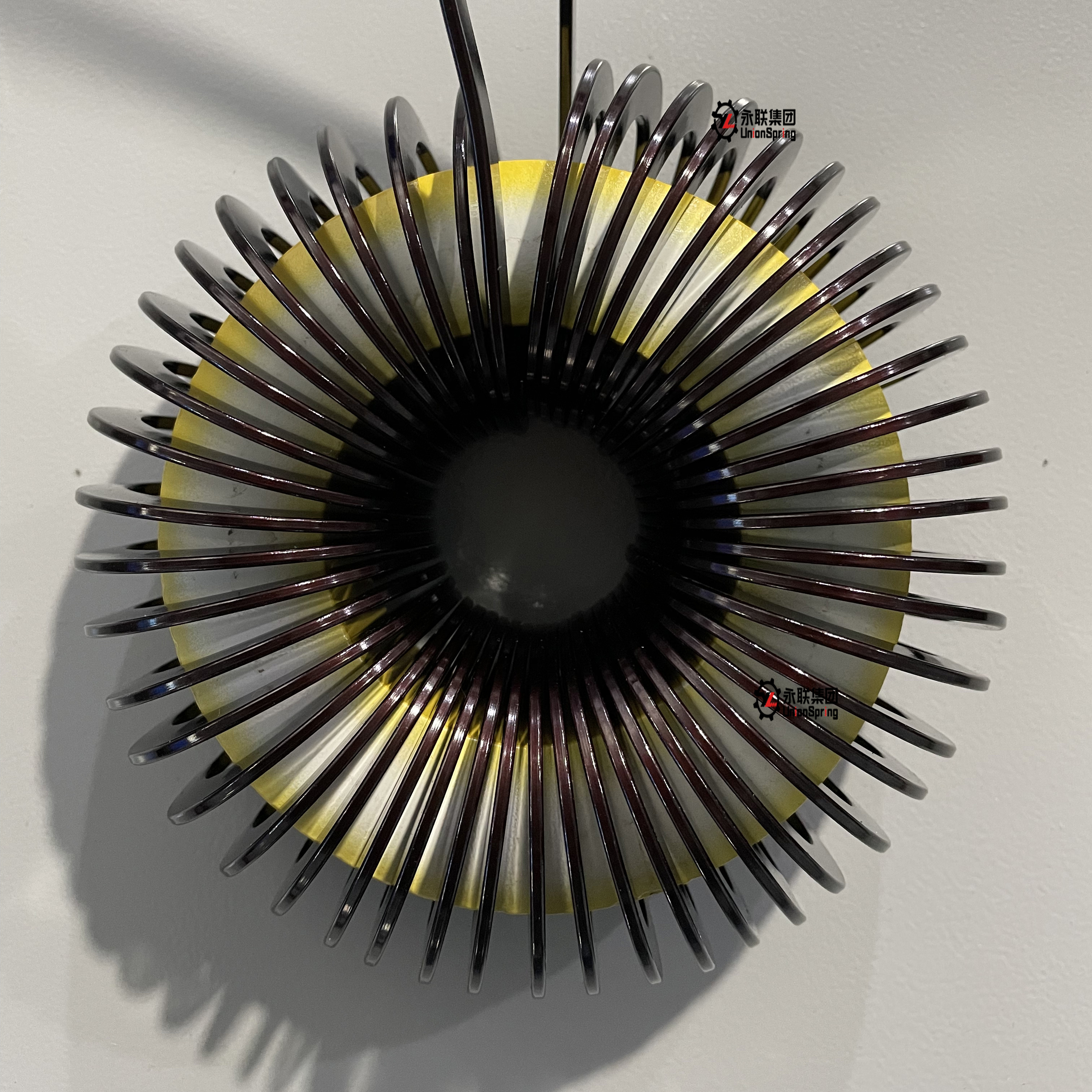

Coil Type:

-

toroidal

-

Length of Axis (mm):

-

80 mm

-

Center Height (mm):

-

50 mm

-

Max.Transformer Capacity(kVA):

-

30 kVA

-

Place of Origin:

-

Guangdong, China

-

Brand Name:

-

UnionSpring

-

Motor Power (kw):

-

3

-

Weight (KG):

-

900

-

Dimension(L*W*H):

-

1700*1250*2000

-

Wire Diameter Range (mm):

-

1 - 5 mm

-

Keyword:

-

copper coil forming machine

-

Function:

-

Automatic Winding/ forming

-

Application:

-

Winding/forming core

-

Winding machine Type:

-

Bobbin Winding Machine

-

Accept coil type:

-

copper round/flat wire

-

Wire Diameter:

-

1.0mm~5.0mm

-

Axis:

-

6 pcs

-

Wire Feeding Range:

-

0.1+N+1

-

Cable High:

-

≤60mm

-

Free Axis Max. Work Length:

-

≤70mm

Product Description

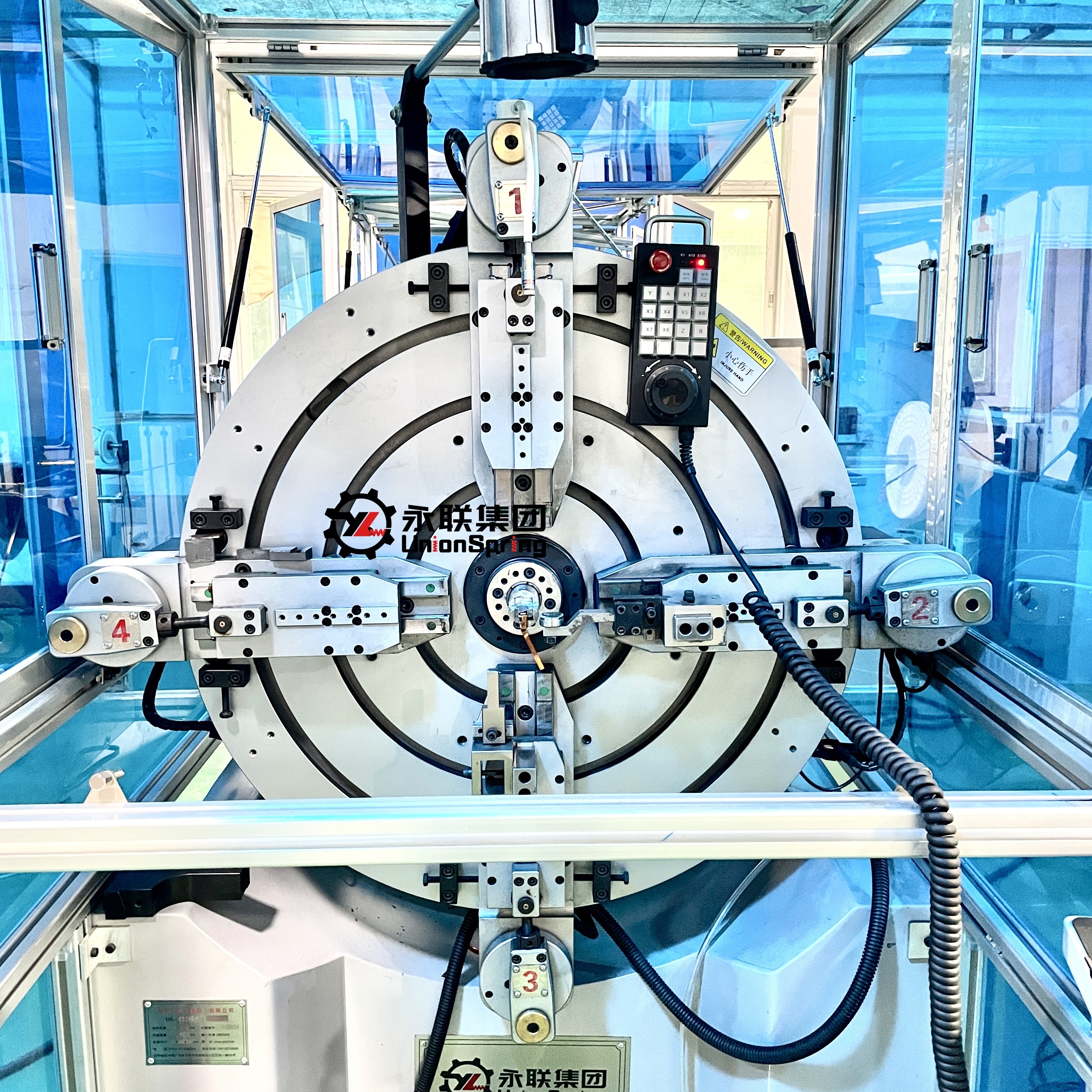

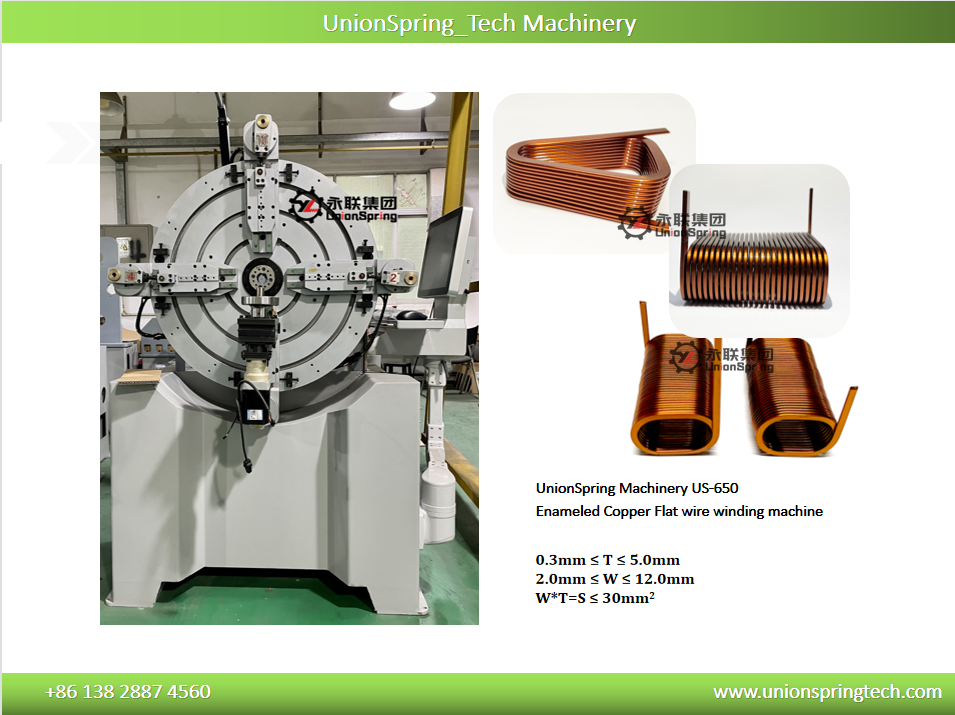

No CAM Winding Square Copper Wire

Coil Inductor Making Machine US-650

|

Model

|

US-650

|

|

Axis

|

6 pcs

|

|

Wire Diameter

|

1.0~5.0mm

|

|

Wire Feeding Range

|

0.1~N+1

|

|

Cables High

|

≤60mm

|

|

Free Arms Max. Work Length

|

≤70mm

|

|

Wire Feeding Servo

|

2.7kw

|

|

Winding Axis Servo

|

0.75

|

|

Arm Axis Servo

|

0.75kw*4

|

|

Machine Size(mm)

|

1700*1250*2000

|

|

Machine Weight

|

900kg

|

Feature 1

1.This US-650 machine uses 6 shafts, which are wire feeding shaft, winding shaft, arm shaft*4. The forming part is completed by the cooperation of the arm shafts. The shaft are independent and interrelated.

Feature 1

2. The machine adopts an independent wire feeding device which can realize single-time, multiple wire feeding, and wire feeding of any length; the rotating core device is located behind the board surface, and the servo is controlled separately, which can realize 360 degree rotation in positive and negative directions

Feature 3

3.The winding shaft is directly installed on the arm shaft, and there are 2 sets of servo synchronous control. It can realize forward and reverse winding, dense winding and variable pitch winding, and can realize single-layer, multi-layer and simple winding.

Feature 4

4.Imported servo, imported planetary reducer transmission high operating accuracy.

Feature 5

5.The machine adopts windows operation interface. which can save the adjustment parameters of products of various specifications.

Packing&Shipping

After Sales Service

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

*Hlep adjust sample

Hot Searches