- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Xingou

-

Model Number:

-

ZA(R)

-

Place of Origin:

-

Hebei, China

-

Horsepower:

-

13kW

-

Outlet Size:

-

1''~18''

-

Power:

-

13kW

-

motor:

-

Electric

Quick Details

-

Application:

-

Mining industry, Wastewater Transport and Flood Control

-

Pressure:

-

Low Pressure

-

Voltage:

-

380V

-

Brand Name:

-

Xingou

-

Model Number:

-

ZA(R)

-

Place of Origin:

-

Hebei, China

-

Horsepower:

-

13kW

-

Outlet Size:

-

1''~18''

-

Power:

-

13kW

-

motor:

-

Electric

Power plant deslagging ore transportation tailings treatment solids transfer mining sand slurry pump

Product Description

ZA(R) type pump is single stage, single suction, cantilever, double shell, horizontal centrifugal slurry pump, this series of slurry pump is widely used in mining, coal, metallurgy, electric power, building materials and other industrial sectors to transport strong abrasive, high concentration slurry. This series of pumps can be applied to a variety of working conditions, is the mine mill slurry, tailings slurry transport of the first choice products.

For high concentration, strong abrasive slurry flow range of 40~80%

The flow rate of medium concentration and medium abrasive slurry ranges from 40 to 100%

For low concentration, low abrasive slurry flow range of 40~120%

| Pump caliber | 1-18cm |

| Rate Of Flow | 5400m3/h |

| Lift Of Pump | 68M |

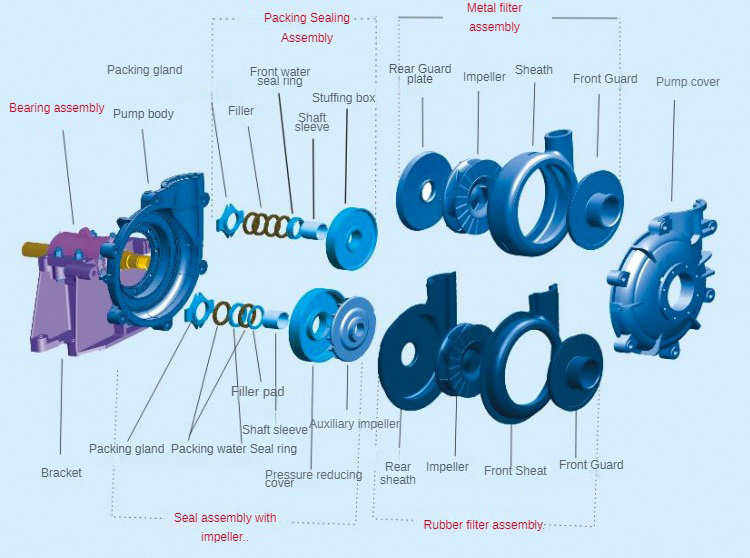

Structural Map

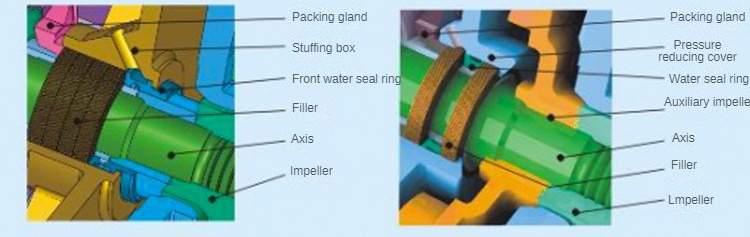

Sealing Method

Packing seal - the most widely used sealing form, through the front water seal ring constantly inject a certain pressure of water inside the packing, to prevent the leakage of the slurry in the pump, for not suitable for the auxiliary impeller seal, more packing seal. Packing seal has simple structure, convenient maintenance and cheap price.

Secondary impeller seal - prevents the slurry from leaking out through a reverse centrifugal force on the impeller. When the positive pressure value of the pump inlet is not greater than 10% of the pump outlet pressure value, the first stage of the single-stage pump or multi-stage series pump can be sealed by the auxiliary impeller, the auxiliary impeller seal has the advantages of no shaft sealing water, no diluting slurry, good sealing effect, etc., so this seal can be considered when the slurry is not allowed to be diluted.

Mechanical seal - for high sealing requirements. In particular, some chemical and food fields not only require sealing, but most importantly, do not allow additional ingredients to enter the pump chamber

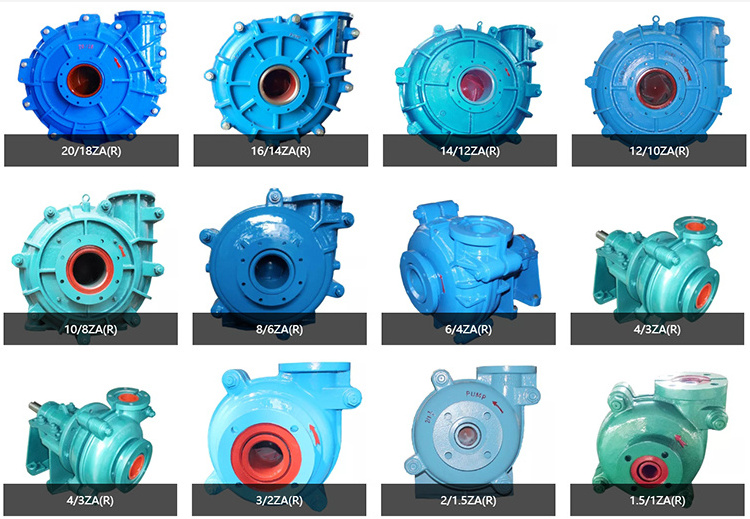

Series Display

Product Drawing And Specification Style