- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Mingxin

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

1300*600*1500mm

-

Motor Power (Kw):

-

18.5

-

Power (kW):

-

18.5

-

Weight (KG):

-

5500 KG

-

Color:

-

Customers' Demand

-

Size:

-

Customers' Demand

-

Capacity:

-

300-400 kg/h

-

Control system:

-

PLC

-

Advantage:

-

High Producing Efficiency

-

Operation:

-

1-2 Workers

-

Feature:

-

High Efficiency Low Cost

-

Motor brand:

-

Chinese Famous Brand

-

Raw material:

-

Iron and steel

-

After-sales Service Provided:

-

Provided

Quick Details

-

Pellet Diameter (mm):

-

6 - 12

-

Output (kg/h):

-

550 - 4200 kg/h

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Mingxin

-

Voltage:

-

380V/50HZ

-

Dimension(L*W*H):

-

1300*600*1500mm

-

Motor Power (Kw):

-

18.5

-

Power (kW):

-

18.5

-

Weight (KG):

-

5500 KG

-

Color:

-

Customers' Demand

-

Size:

-

Customers' Demand

-

Capacity:

-

300-400 kg/h

-

Control system:

-

PLC

-

Advantage:

-

High Producing Efficiency

-

Operation:

-

1-2 Workers

-

Feature:

-

High Efficiency Low Cost

-

Motor brand:

-

Chinese Famous Brand

-

Raw material:

-

Iron and steel

-

After-sales Service Provided:

-

Provided

Biomass Pellet Machine

Product Introduction

Wood pellet machine is a biomass new energy source equipment and the granulation equipment of wood chips production. It is eucalyptus, birch, poplar, fruit trees, bamboo chips and crop straw as raw materials. Through the crushing, drying, screening, granulation, cooling, packaging and other processes to produce finished wood chips. Its products are used in biomass power generation, boilers, fireplaces, household appliances and so on.

Flat type

Biomass Pellet Machine

Ring type

Biomass Pellet Machine

Wood pellet machine features and technical advantages:

All typical features of a conventional vertical ring mold particle machine:

1. Vertical feed, directly in place.

2. The mold is still, pressure roller rotation, material centrifugal, evenly around.

3. The mold has two layers, up and down dual-use, cost reduction efficiency; can also be dual-use, high-yield energy.

4. Annular mold, vertical structure, which facilitates the cooling of the granulation chamber.

5. Separate discharge device to ensure the formation rate of particles.

6. Independent automatic lubrication system brings a good bearing lubrication effect.

7. Feeding system has a frequency conversion device and achieves the adjustable of feeding speed. It can promise the different materials.

Feature improvement

1.Following the acclaimed industrial-grade reducer drive structure and further optimize the speed ratio, make the perfect combination of the transmission efficiency and durability. Its excellent performance is not a simple gear or belt drive models can be compared.

2.Change "blocking" as "sparse". From the structure to start, completely change the particle mechanism of particles in the long-term use of raw materials after the increase in the shortcomings of leakage.

3.Optimizing automatic lubrication system. In the realization of no downtime can automatically lubricate the various parts of the machine, on the basis of the bearing and further equipped with a pressure valve to stimulate the amount of grease filling and timely automatic adjustment. It can achieve truly perfect lubrication and save per gram of grease.

4.Optimizing the granulation chamber of the material device, once again enhance the granulation efficiency and quality.

5.Using traditional alloy material to product, and on the basis of the pressure roller manufacturing process of heat treatment. Then carrying out second special treatment. So that the durability of the pressure roller on the next level and achieve the current industry-leading level.

Technical parameter of

Wood pellet machine

|

Model

|

Power(kw)

|

Capacity(kg/h)

|

Dimension(mm)

|

Weight(kg)

|

|

300A

|

18.5

|

250-300

|

1300*600*1500

|

600

|

|

300B

|

22

|

300-350

|

1300*600*1500

|

600

|

|

400A

|

30

|

500-550

|

1450*700*1700

|

900

|

|

400B

|

37

|

550-600

|

1500*700*1700

|

900

|

Details Images

Working principle of Cheap price charcoal briquette making machine

First, the machine adopts the motor direct connection. The motor is connected to the gear shaft via a gear coupling. Through the

gear 90 ° change, horizontal motor drive vertical hollow spindle. The spindle drives the press roll to crush the inner surface of

the mold to complete the pressing process. When it’s working, the material falls vertically on the surface of the shelf plate by

the drawing inlet. Through the rotation of the shelf plate to make the material evenly in the mold cavity surface.(The contact

surface of the press roller with the mold) The powder material passes through the hole of the mold under the rolling of the press

roll.(Evenly distributed in the mold on the surface of the hole) This process is subject to high pressure, high temperature,

physical changes or appropriate chemical changes.(According to material) It promotes the powder material to form a continuous

cylindrical solid body. The cylindrical solid body is continuously extended until it is cut by the cutter around the uniform mold

to form a certain size of the particles. The particles scattered around the mold are concentrated from the teeth to the discharge

port. The particles are automatically dropped under the action of gravity, and the granulation process is completed. Note: All

port.

parts of the machine are installed on the machine surface machining, assembly accuracy, excellent machine performance.

Raw Material

The biomass pellet machine is applied to the material with low adhesiveness and low shaping ,such as the rice husk, sunflower seed husk, peanut shell and other fruit shell branch, trunk, bark and other wood waste; a variety of crop straws, rubber, cement ,ash and other chemical materials. The pellet machine is widely used in the feed plant, wood processing, fuel plant, fertilizer plant and chemical plant etc. It is the ideal pressing shaping equipment with low investment and high profit.

1. Raw materials diameter requirement : 3-5mm(If large ,crusher machine should be used)

2. Raw materials moisture:15-25%.(If beyond the scope,dryer machine should be used )

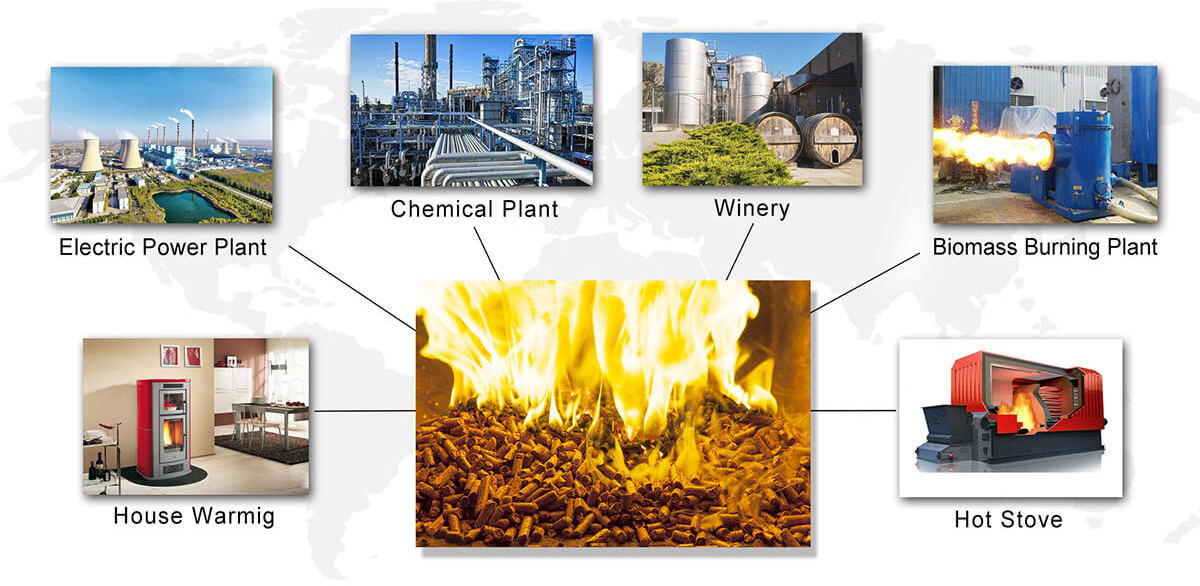

Widely Application

Our Company

Henan Mingxin Machinery Co., Ltd is a company that integrates science, industry and trade. The company mainly sells mechanical equipment and accessories, pipeline equipment, refractory materials, abrasive materials, water purification equipment, wire and

cable. Our company follows the human-oriented, honest, pioneering entrepreneurial spirit with scientific and technological

innovation. We have always regarded the technology as the motive force, the market as the orientation to make the products

first-class.

Our company insists on the professional development based on the principle of innovation and honesty. We win the market with our advanced skills, high-quality products and considerate services.The products in our company have been exported to the South Africa, Pakistan, Vietnam and other counties with the advanced technology, reliable quality and reasonable price. We have also got the good reputations from customers at home and abroad.

Packing & Delivery

Inner package of

Wood pellet machine

:

Plastic packing

Outer package of

Wood pellet machine

:Wooden case

Delivery of

Wood pellet machine

:Within 15 days after order

FAQ

Q: How about the quality of your products?

A:We put the quality in the first place based on the honesty. Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before the delivery. You can also use Trade Assurance by Alibaba for product quality protection, punctual shipment protection and payment protection.

Q: How about the price?

A: We pursue small profits but quick turnover, and we can give you lower price than other trading companies. Besides, customers from Alibaba can get a discount. If the product is really suitable and can benefit you, the price is negotiable.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to solve your problems promptly and thoroughly.

A:We put the quality in the first place based on the honesty. Our machines are manufactured strictly according to national and international standards, and we take a test on each equipment before the delivery. You can also use Trade Assurance by Alibaba for product quality protection, punctual shipment protection and payment protection.

Q: How about the price?

A: We pursue small profits but quick turnover, and we can give you lower price than other trading companies. Besides, customers from Alibaba can get a discount. If the product is really suitable and can benefit you, the price is negotiable.

Q: Do you provide after-sale service?

A: Yes. The warranty period of our machines is one year, and we have a professional after-sale service team to solve your problems promptly and thoroughly.

Hot Searches