*Wide scope of application:

Not only suitable for the common hard cover papers, but also suitable for the leather and other materials.

*Lower cost:

Micro thermal protein glue dry quickly, no deformation and lower cost.

*Easy operation:

Reciprocating automatic edge fold system fold two edges automatically at one time.

High speed optical fiber detection control the length and position of the paper feeding accurately.

- Product Details

- {{item.text}}

Quick Details

-

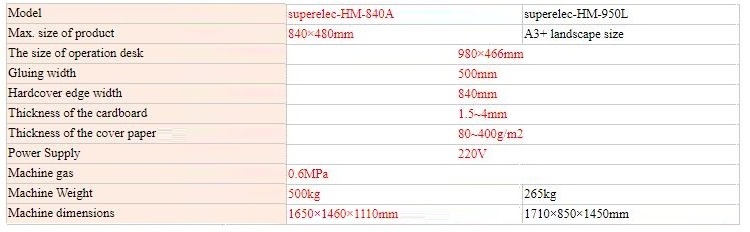

Voltage:

-

220V

-

Dimension(L*W*H):

-

1650*1460*1110mm

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

Overseas third-party support available

-

Product name:

-

Hard Cover Making Machine, Book Cover Maker

-

Model:

-

superelec-HM-840A

-

Max. size of product:

-

840*480mm

-

The size of operation desk:

-

980*466mm

-

Gluing width:

-

500mm

-

Hardcover edge width:

-

840mm

-

Thickness of the cardboard:

-

1.5-4mm

-

Thickness of the cover paper:

-

80~400g/m2

-

Machine gas:

-

0.6MPa

Quick Details

-

Type:

-

hardcover making machine

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

superelec

-

Voltage:

-

220V

-

Dimension(L*W*H):

-

1650*1460*1110mm

-

Weight:

-

500 KG

-

After-sales Service Provided:

-

Overseas third-party support available

-

Product name:

-

Hard Cover Making Machine, Book Cover Maker

-

Model:

-

superelec-HM-840A

-

Max. size of product:

-

840*480mm

-

The size of operation desk:

-

980*466mm

-

Gluing width:

-

500mm

-

Hardcover edge width:

-

840mm

-

Thickness of the cardboard:

-

1.5-4mm

-

Thickness of the cover paper:

-

80~400g/m2

-

Machine gas:

-

0.6MPa

Product Description

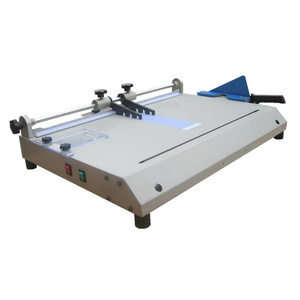

Semi-auto Hardcover Book Case Maker Hard Cover Making Machine Book Cover Maker

Semi-auto Hardcover Book Case Maker Hard Cover Making Machine Book Cover Maker

Semi-auto Hardcover Book Case Maker Hard Cover Making Machine Book Cover Maker

Features of Semi-auto Hardcover Book Case Maker

*Multi-functions:

Independent homo-thermal impermeable heater unit can use both protein glue (hot) and white latex (cold).

Quantitative filling the water automatically and the water yield can be adjusted.

Step-less glue application speed.

Soft light reflection and center position.

Standard and three spines hard covers are available by change and add the spine guides quickly.

The corner cutter can cut four standard corners on different thickness of cardboard without adjustment.

Paper guides go up and down and controlled by pneumatic foot valve.

*Easy installation:

Split type model can enter into elevator door and office door.

Glue part can be choosed to set on the Left/Right side, the standard model is on the Left side.

Equipped with high load casters, convenient to level adjusting, fixing and moving the machine.

ST840A can be operated by one person, protein glue (Hot) and white latex (cold) are both available, fold two edges automatically at one time.

It also has the functions like corner cutter, Quantitative filling the water, fast to adjust the thickness of the cardboard, soft light reflection, center position and cover suction assistance.

Independent homo-thermal impermeable heater unit can use both protein glue (hot) and white latex (cold).

Quantitative filling the water automatically and the water yield can be adjusted.

Step-less glue application speed.

Soft light reflection and center position.

Standard and three spines hard covers are available by change and add the spine guides quickly.

The corner cutter can cut four standard corners on different thickness of cardboard without adjustment.

Paper guides go up and down and controlled by pneumatic foot valve.

*Easy installation:

Split type model can enter into elevator door and office door.

Glue part can be choosed to set on the Left/Right side, the standard model is on the Left side.

Equipped with high load casters, convenient to level adjusting, fixing and moving the machine.

ST840A can be operated by one person, protein glue (Hot) and white latex (cold) are both available, fold two edges automatically at one time.

It also has the functions like corner cutter, Quantitative filling the water, fast to adjust the thickness of the cardboard, soft light reflection, center position and cover suction assistance.

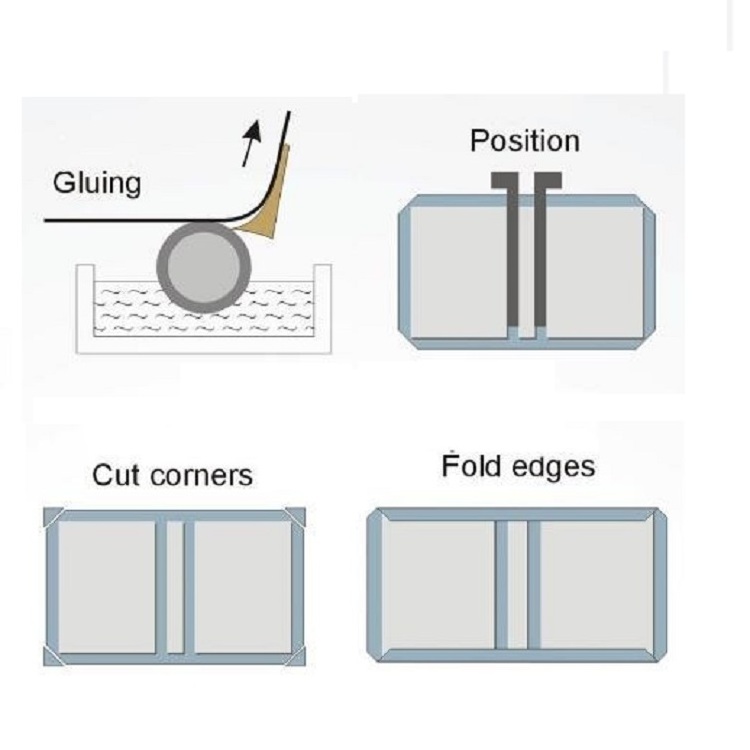

Four steps to make hard covers:

* High accuracy glue roller makes the glue ell-distributed.

* Copper alloy made glue application roller and glue reservoir make the heat conduction fast and well distributed.

* Quantitative water filling device fill proper amount of water according to the use conditions which avoid the glue from drying

and soliding.

* Independent homo-thermal impermeable heater unit, protein glue, jelly glue and white latex can be used separately.

* The thickness of the glue can be adjusted.

* Copper alloy made glue application roller and glue reservoir make the heat conduction fast and well distributed.

* Quantitative water filling device fill proper amount of water according to the use conditions which avoid the glue from drying

and soliding.

* Independent homo-thermal impermeable heater unit, protein glue, jelly glue and white latex can be used separately.

* The thickness of the glue can be adjusted.

1.Hot gluing:

Spread the glue on the back of the cover uniformly.

2

.Suction and Position:

Bound the cardboard and spine with cover paper.

3.

Corner cutter:

Cut four corners of the cover paper

.

4

.Automatic edge folding:

Put the bound cardboard into the edge folder and the edges will be folded automatically.

Products:

Recommend Products

Contact us

If you have any qustion,contact us at any time!

E-mail:peter@superelec.cn

Tel/Whats App:+86 13663008617

Tel/Whats App:+86 13663008617

Packaging & Shipping

SHIPPING

1.By air, sea or combined transportation.

2.Express via FEDEX, TNT, UPS, DHL, EMS(AS your request)

3.Tracking Number will offer you immediately after delivery

3.Tracking Number will offer you immediately after delivery

4.Shipping cost depends on the shipping method, product quantity,weight, carton size and your area.

PACKAGING

|

Packaging Details

|

|

Stong wooden box package

|

|

|

Port

|

|

The main ports in China, depends customers choice

|

|

|

Lead Time

|

1 pc

|

35 days

|

|

|

|

>1 pcs

|

To be negotiated

|

|

First Step:

Machine packing with wooden base

Second step:

Machine packing with film to water proof

Third step:

Machine packing with wooden case

Fouth step:

Machine with wooden base packing load to container

Our Services

Hot Searches