- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Product name:

-

MPCVD system

-

Application:

-

Diamond grown

-

Chamber material:

-

SS304

-

Microwave:

-

2450MHz

-

Microwave source:

-

Sairem

-

Gas channel:

-

4

Quick Details

-

Warranty:

-

1 year

-

Brand Name:

-

TN

-

Model Number:

-

TN-MPCVD

-

Place of Origin:

-

Henan, China

-

Product name:

-

MPCVD system

-

Application:

-

Diamond grown

-

Chamber material:

-

SS304

-

Microwave:

-

2450MHz

-

Microwave source:

-

Sairem

-

Gas channel:

-

4

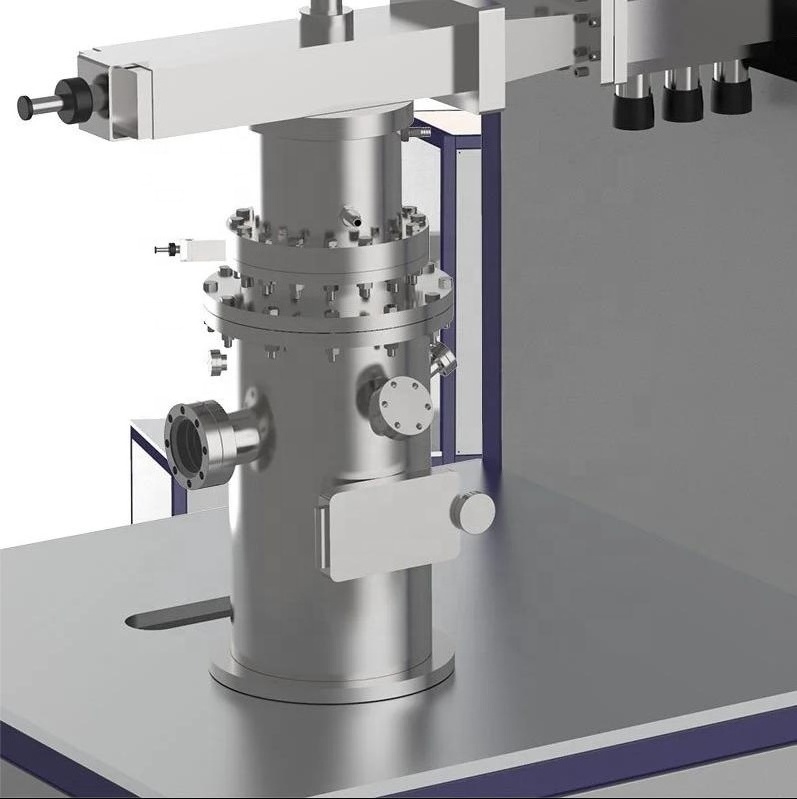

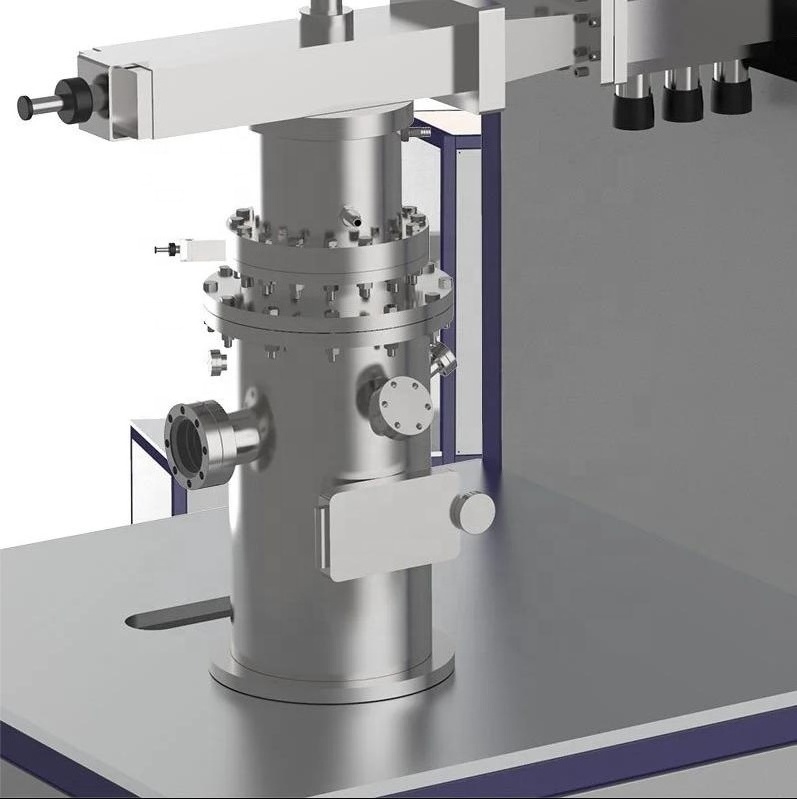

6kw Mpcvd Machine for CVD Diamond Growth Lab Diamond Making Machine

Lab6kw Mpcvd Machine for CVD Diamond Growth Lab Diamond Making Machine

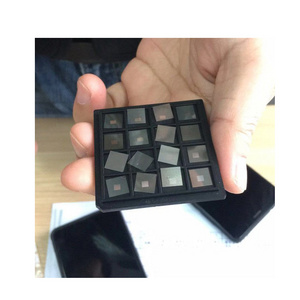

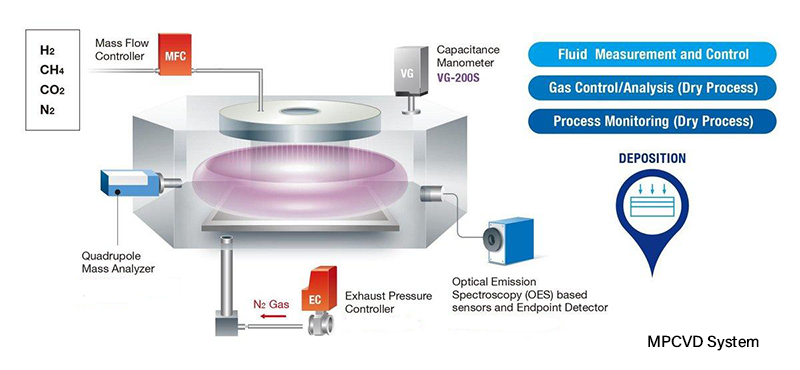

The trend in lab grown diamonds (LGD) is the use of MPCVD (microwave plasma CVD) equipment, which grows diamonds artificially by volumizing carbon (C) on a substrate. It is said to be currently capable of producing 20-carat diamonds. when CH4 and H2 are mixed and excited by microwaves, a glow discharge occurs in a vacuum vessel. Molecules of the reactant gases are ionized and a plasma is generated.

In its CVD process, TN's high-quality gas flow control technology, pressure monitoring product and pressure control solution are used. TN solutions ensure consistent quality diamond growth.

Specifications of MPCVD diamond grown system

|

Microwave system |

microwave frequency |

2450±25MHz |

|

output power |

0.6kw~6kw continuous adjustable |

|

|

Microwave tuning |

3-stub tuner Mode conversion antenna |

|

|

Microwave reflection protection |

Circular,Water load |

|

|

Microwave operating mode |

TM013 |

|

|

microwave leak |

≤ 2 mw/cm2 |

|

|

Vacuum system |

Operating pressure range |

10~250Torr |

|

Automatic pressure control |

40~250Torr |

|

|

Vacuum pump |

4.4L/s rotary-vane vacuum pump |

|

|

Vacuum integrity |

< 1.0x10 -9 Pa * m 3 /sec (by Helium leak detector) |

|

|

Pressure holding capacity |

The pressure rise is less than 0.2 Torr every 24 hours |

|

|

Ultimate vacuum |

0.1Pa(7.5 x10 -4 Torr) |

|

|

Vacuum measurement |

Brand film gauge |

|

|

Vacuum reactor |

Reactor materials and structures |

double-layer water-cooled stainless steel |

|

Vacuum seal |

Metal seal + fluororubber ring seal (load door) |

|

|

Reactor ID |

φ140mm |

|

|

Sample table window |

105x50mm Rectangular port, Front door sealed with Fluorine O-ring |

|

|

Watch window |

Two ports, CF35 large bore, 180 ° distribution |

|

|

Temperature measurement window |

The horizontal angle of the two windows is 25~30°, 180° distribution; The window is convenient to detect the temperature of the sample stage from the oblique angle of the upper part of the reactor downward |

|

|

Sample stage |

Electric lift water-cooled substrate platform φ100mm,Adjustable height range 0~70mm |

|

|

When the diameter of molybdenum substrate is ≥50mm, the plasma fireball can cover the whole substrate stage at 5000W and 180torr |

||

|

Substrate temperature 250~1400ºC Depending on the process parameters |

||

|

Gas channel |

Flowmeter and flow control valve imported from Japan |

|

|

system-provided 4-channel MFC |

||

|

4MFC maximum flow:H2: 1000sccm,CH4:100sccm,O2:20sccm,N2:2sccm |

||

|

Temperature measurement system |

German Raytek infrared temperature measurement system, temperature range: 300 ~ 1300 ºC |

|

|

Systems software |

15"touch screen with PLC control, friendly user operating interface |

|

|

The system supports two levels of users: engineer and operator, and provides user authority management function |

||

|

The system is equipped with automatic protection such as water shortage, air shortage, power supply phase failure, fireball jump, over temperature overload, ignition and so on |

||

|

Up to 10 sets of process recipes can be set, each set has 40 rows of data, the production process is automatically controlled by the process recipes, and the process data can be backed up and exported via U disk |

||

|

The system comes with fully automatic air extraction, ignition, heating, cooling and other preset processes, easy for users to operate |

||

|

Fully automatic temperature control and air pressure control greatly reduce the workload of system operators |

||

Detailed pictures of MPCVD system