- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

OEM

-

Liquid Flow Rate:

-

100 L/Min

-

Maximum Working Pressure:

-

60bars

-

Weight:

-

5 KG

-

Working Temperature Range:

-

-30℃ to 50℃

-

Product Name:

-

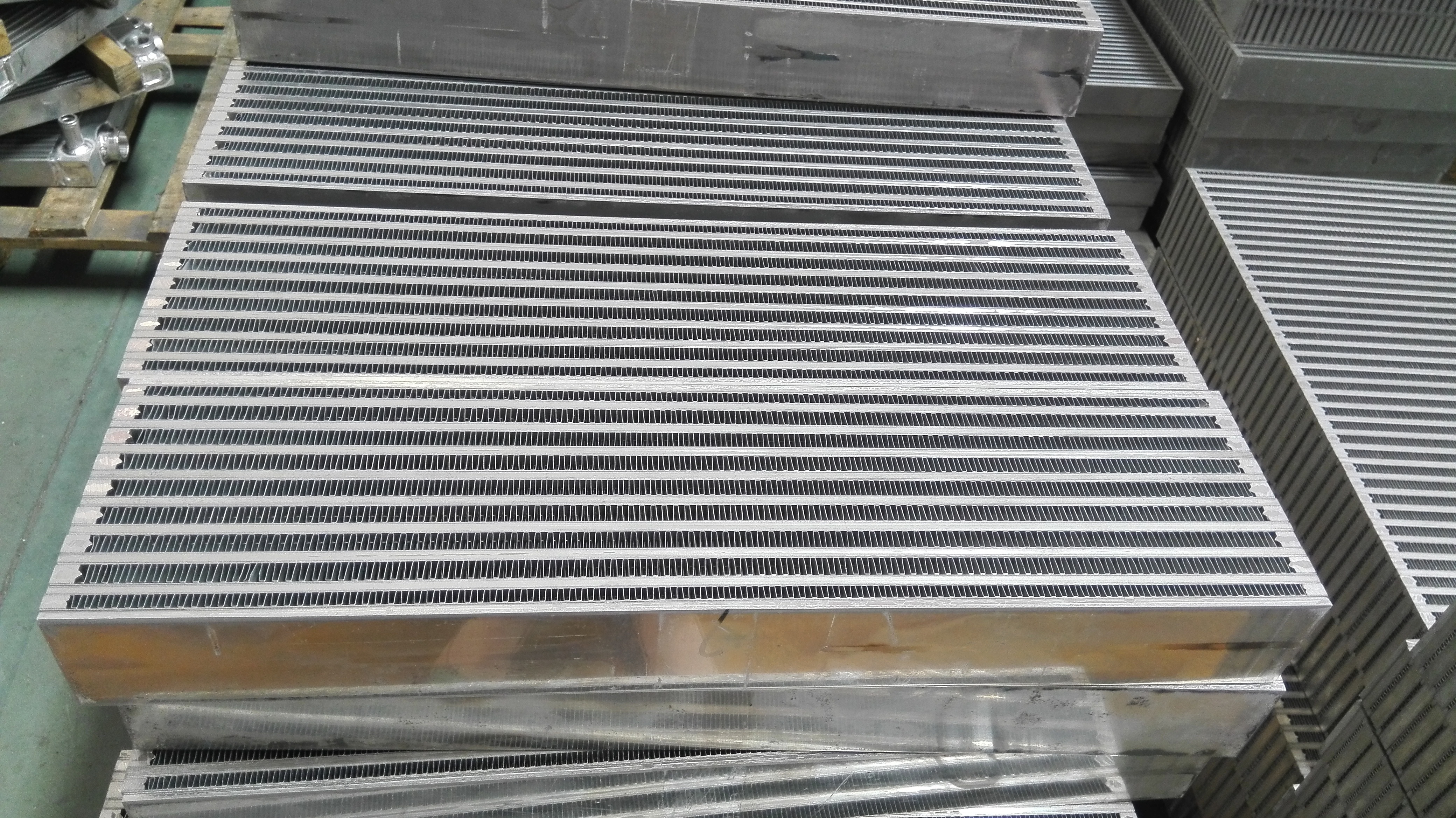

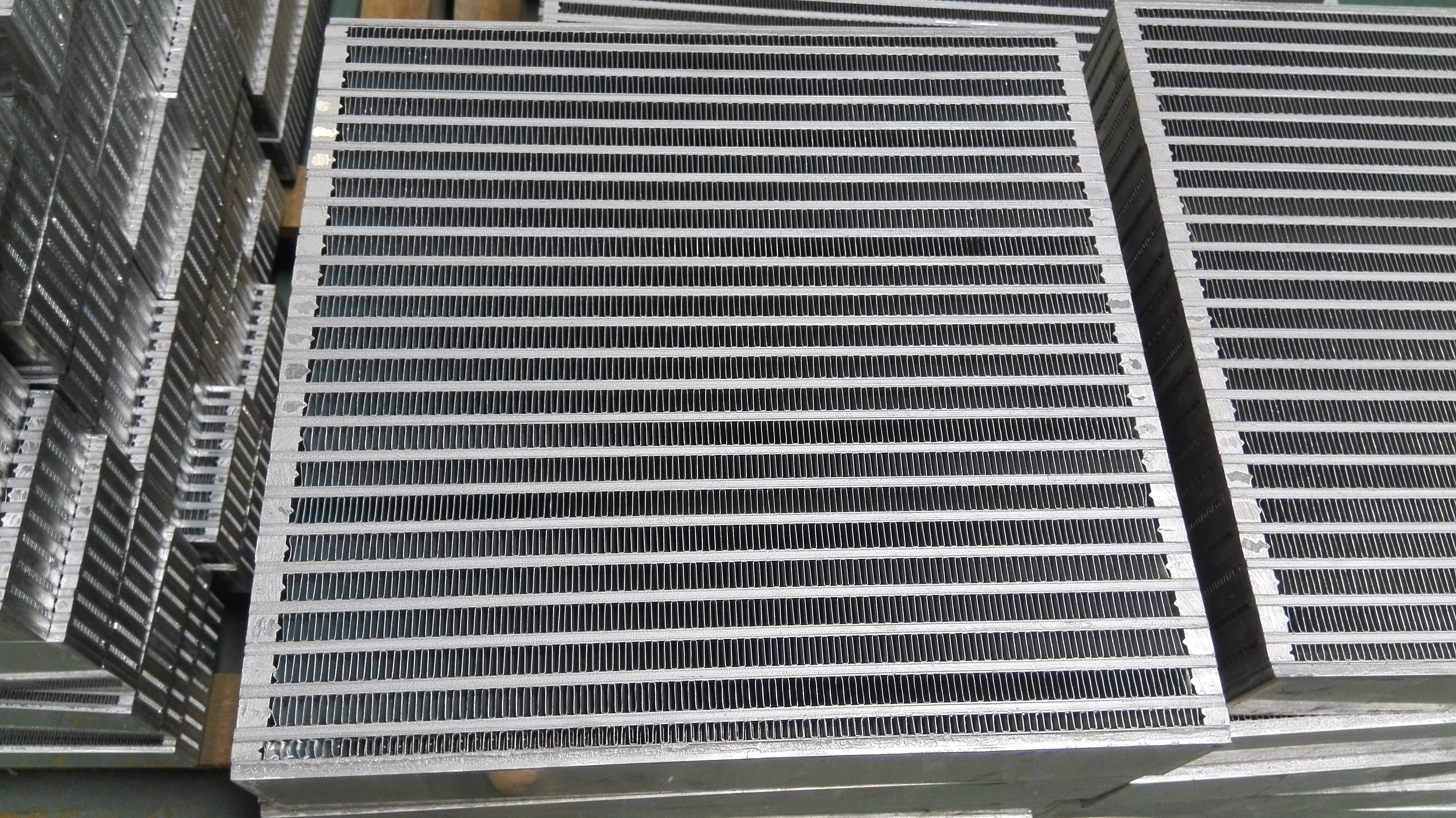

oil cooler core

-

Outer fin type:

-

Wavy fin/Louver fin

-

Inner fin:

-

Serrated fin/offset fin

-

Fin material:

-

Auminum Fin

-

Type:

-

Plate fin heat exchanger

-

Fluid material:

-

Oil

-

Main technique:

-

Vacuum brazing

-

Surface finish:

-

Mill finish or custom

-

Certification:

-

CE

-

Material:

-

Aluminum Alloy

Quick Details

-

Structure:

-

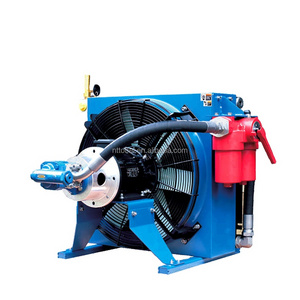

Plate Heat Exchanger

-

Voltage:

-

220V

-

Place of Origin:

-

China

-

Brand Name:

-

OEM

-

Liquid Flow Rate:

-

100 L/Min

-

Maximum Working Pressure:

-

60bars

-

Weight:

-

5 KG

-

Working Temperature Range:

-

-30℃ to 50℃

-

Product Name:

-

oil cooler core

-

Outer fin type:

-

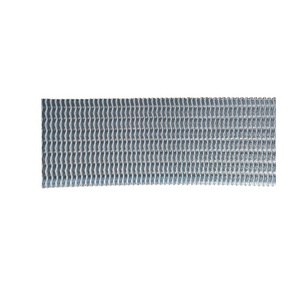

Wavy fin/Louver fin

-

Inner fin:

-

Serrated fin/offset fin

-

Fin material:

-

Auminum Fin

-

Type:

-

Plate fin heat exchanger

-

Fluid material:

-

Oil

-

Main technique:

-

Vacuum brazing

-

Surface finish:

-

Mill finish or custom

-

Certification:

-

CE

-

Material:

-

Aluminum Alloy

Heat exchanger core, made from high quality aluminum alloy, provides outstanding heat exchange capabilities, largely improving thermal performance.

New type of both internal and external cores features a completely new take on core's fins arrangement, resulting in improved heat exchange and air flow. Alternately placed heat exchanger fins significantly improve cooling capabilities.

|

NO.

|

ITEM DESCRIPTION

|

CONTENT

|

|

|

||

|

1

|

Product name

|

hydraulic oil cooler core

|

|

|

||

|

2

|

Pettern

|

AH1012T-CA

|

|

|

||

|

3

|

Rate of flow

|

100L/min

|

|

|

||

|

4

|

Working pressure

|

≤2MPa

|

|

|

||

|

5

|

6Fan power

|

60W

|

|

|

||

|

6

|

Fan voltage

|

AC220V/380V DC12V/24V

|

|

|

||

|

7

|

Exterior cooling area

|

2.6m²

|

|

|

||

|

8

|

The warranty

|

12 months

|

|

|

||

Liquid cooling plate

Heat exchanger parts aluminum fin

Nanjing Metalli-your ideal partner for thermal management and metal fabrication solutions

✅ Since 2008, Nanjing Metalli has been focusing on thermal management field. Our capabilities cover a wide range that provide you one-stop solution quicker and easier. Our main capabilities include:

◇ Vacuum Brazing and Controlled Atmosphere Brazing

◇ CNC machining

◇ Welding

◇ Aluminum extrusion

◇ Aluminum die casting

◇ Sheet metal fabrication covering laser cutting, stamping, drawing and bending

◇ Surface coating

✅We emphasis prototype process. we use our vast experience in fluid dynamics, thermal performance, and material compatibility to optimize your design. To perform advanced thermal analysis, our engineers use simulation software like CFD, 6 Sigma. In addition to providing expert thermal and mechanical design engineering, we ensure that your products fit DFM concept so that your products can be built to your exact specifications as well as meet your delivery schedule.

✅ We see quality aspects from manufacturing viewpoints. Focusing more on monitoring and minimizing process variable to keep stable quality level. Delivered products are performed 100% inspection or testing. Less worries of quality risk and loss

✅ Our lean manufacturing and continuous improvement program aim at eliminating all wastes that do not add values. Our customers do not need to pay for wastes. The cost will be more and more competitive that help grow up your business and build your success.

◇ Vacuum Brazing and Controlled Atmosphere Brazing

◇ CNC machining

◇ Welding

◇ Aluminum extrusion

◇ Aluminum die casting

◇ Sheet metal fabrication covering laser cutting, stamping, drawing and bending

◇ Surface coating

✅We emphasis prototype process. we use our vast experience in fluid dynamics, thermal performance, and material compatibility to optimize your design. To perform advanced thermal analysis, our engineers use simulation software like CFD, 6 Sigma. In addition to providing expert thermal and mechanical design engineering, we ensure that your products fit DFM concept so that your products can be built to your exact specifications as well as meet your delivery schedule.

✅ We see quality aspects from manufacturing viewpoints. Focusing more on monitoring and minimizing process variable to keep stable quality level. Delivered products are performed 100% inspection or testing. Less worries of quality risk and loss

✅ Our lean manufacturing and continuous improvement program aim at eliminating all wastes that do not add values. Our customers do not need to pay for wastes. The cost will be more and more competitive that help grow up your business and build your success.

Vacuum Brazing Furnace

CNC Machine

100% tested or Inspected

Hot Searches