- Product Details

- {{item.text}}

Quick Details

-

Blade Length (mm):

-

2500 mm

-

Backgauge Travel (mm):

-

20 - 800 mm

-

Throat Depth (mm):

-

200 mm

-

Brand Name:

-

MC

-

Power (kW):

-

15 kW

-

Weight (KG):

-

12600 KG

-

Place of Origin:

-

China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3280X2100X2300

-

Year:

-

2020

-

Name:

-

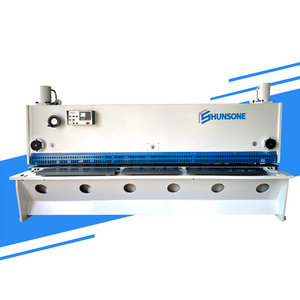

Hydraulic Cnc Plate shearing machine,plate shearing machine

-

Machine body:

-

Steel plate welded frame

-

Cutting method:

-

Hydraulic power

-

Cutting angle:

-

Adjustable

-

Use in:

-

Metal forming industry

-

Products:

-

Different kinds of sheet type

-

Named:

-

Guillotining shear machine

-

Title:

-

Sheet metal cutting machine

-

Weight:

-

12600kg

-

Rated Power:

-

15KW

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

-

Certification:

-

CE & ISO

Quick Details

-

Max. Cutting Width (mm):

-

2500

-

Max. Cutting Thickness (mm):

-

25 mm

-

Shearing Angle:

-

1-2

-

Blade Length (mm):

-

2500 mm

-

Backgauge Travel (mm):

-

20 - 800 mm

-

Throat Depth (mm):

-

200 mm

-

Brand Name:

-

MC

-

Power (kW):

-

15 kW

-

Weight (KG):

-

12600 KG

-

Place of Origin:

-

China

-

Voltage:

-

220V/380V

-

Dimension(L*W*H):

-

3280X2100X2300

-

Year:

-

2020

-

Name:

-

Hydraulic Cnc Plate shearing machine,plate shearing machine

-

Machine body:

-

Steel plate welded frame

-

Cutting method:

-

Hydraulic power

-

Cutting angle:

-

Adjustable

-

Use in:

-

Metal forming industry

-

Products:

-

Different kinds of sheet type

-

Named:

-

Guillotining shear machine

-

Title:

-

Sheet metal cutting machine

-

Weight:

-

12600kg

-

Rated Power:

-

15KW

-

After-sales Service Provided:

-

Field installation, commissioning and training, Field maintenance and repair service, Online support, Video technical support

-

After Warranty Service:

-

Video technical support, Online support

-

Local Service Location:

-

None

-

Certification:

-

CE & ISO

E21 system Wire mesh stainless steel guillotine cutter qc11k-25/2500 billet shearing machine

- Streamlined looking,Frame: consists of right and left wall boards, working table, oil box, slot steel and etc. The stress of the welded parts can be eliminated by vibration. The machine enjoys high accuracy and high strength and can be transported easily.

- As the cutting beam has been designed in inner-inclined structure, it is easy for plates to fall down and the accuracy of products can also be guaranteed.

- High accuracy, high efficiency, simple and convenient operation, good performance, favorable price and best service.

-The machine by CE certification and ISO quality system certification

|

Model MCNC |

Shearing Thickness |

Shearing Width |

Strokes | Back gauge Range |

Shearing Angle |

Main Motor Power |

| (mm) | (mm) | (time/min) | (mm) | (.) | (kw) | |

| 4*3200 | 4 | 3200 | 18 | 20-500 | 1 30’ | 5.5 |

| 6*3200 | 6 | 3200 | 14 | 20-500 | 1 30’ | 7.5 |

| 8*3200 | 8 | 3200 | 12 | 20-500 | 1 30’ | 11 |

| 10*4000 | 10 | 4000 | 12 | 20-600 | 1 30’ | 15 |

| 12*6000 | 12 | 6000 | 6 | 20-600 | 1 30’ | 22 |

| 12*8000 | 12 | 8000 | 5 | 20-600 | 1 30’ | 22 |

| 16*3200 | 16 | 3200 | 12 | 20-600 | 2 | 22 |

| 16*4000 | 16 | 4000 | 8 | 20-600 | 2 | 22 |

| 20*4000 | 20 | 4000 | 5 | 20-600 | 2 30’ | 30 |

| 25*4000 | 25 | 4000 | 6 | 20-600 | 2 30’ | 37 |

| 32*3200 | 32 | 3200 | 5 | 20-600 | 3 | 37 |

| 40*3200 | 40 | 3200 | 5 | 20-600 | 3 | 45 |

| 50*3000 | 50 | 3000 | 5 | 20-600 | 3 | 90*3 |

| 50*6000 | 50 | 6000 | 5 | 20-600 | 3 | 90*5 |

| 60*3500 | 60 | 3500 | 5 | 20-600 | 3 30’ | 90*4 |

- Electrical components are imported or from Sino-foreign joint Venture,in accordance with international standards,reliable safety,long life,good anti-interference ability.

- Protective fence and the safety interlock to ensure the operation safety. Have a movable single-hand pedal switch,easy to operate.

- Emergency stops on machine and foot switch for safety and Fence like body guard is standard or light curtain is optional.

The famouse brand for Motor ,Gear pump ,Hydraulic system,Ball screw and line guide ,Sealing rings ect.

Accessoris and spares for plate shearing machine

|

No. |

Item |

Quantity |

Remark |

|

1 |

Motor |

1Set |

Siemens(China) |

|

2 |

Gear pump |

1Set |

Sunny(USA) |

|

3 |

Casting connector |

1Set |

Cast CO.(Italy) |

|

4 |

Main electric parts |

1Set |

Siemens(China) |

|

5 |

Hydraulic system |

1Set |

Rexroth(Germany) |

|

6 |

Sealing rings |

1Set |

Valqua CO.(Japan) |

|

7 |

Blade |

1Set |

Jinshan(China) |

|

8 |

Ball screw and line guide |

1Set |

Hiwin(Taiwan,China) |

|

9 |

Safety light curtain |

1Set |

Lntech(China) |

|

10 |

E21 CNC System |

1Set |

ESTUN(China) |

1.Management objective

Quality roots in responsibility, honesty creates value.

Strives for perfection, the good faith for this, the customer is supreme, for customer creation value.

We insist, pragmatic, pioneering and the principle of good faith.

2.Sourcing Solutions

Detail matters!It is our policy to ensure we understand your product or range requirements 100% before selecting the right manufacture for you.

3.Quality Control

We arranged professional person to test each one machine before sending goods to foreign countries.

we are not send unqualified equipment to abroad.

4.After-sales

We put a lot of hard work into making sure we supply you with the products you want,so why wouldn’t we want to hear about your success with them?we also know that sometimes,issues do arise.your feedback is vital for us to continue to improve.

One year warranty will be offered, we will provide with some accessories that is broken within one year after the factory inspection date (see factory inspection sheet).Accessories will be sent by common mail or sea freight.

5.Documents:

We offer the following documents for customs clearance, if you require extra documents please inform us in advance.

1) 3 Original B/L

2) 3 Original Commercial Invoice

3) 3 Original Packing List

4) 1 Original Insurance Certificate (for C.I.F term)

5) 1 Original certificate (if necessary)

The working conditions and environments used are:

1. Input power: 380V ± 5% / 50Hz ± 1, three-phase five-wire (according to customer requirements) or Input power: 220V ± 5% / 60Hz ± 1, three-phase

2. Ambient temperature: 0℃-45℃

3. At 40 ℃: relative humidity≤50%; at 20℃: relative humidity≤85%

The use of occasions should not seriously affect the use of welding gas, steam, chemical deposition, dust, mold and other easy fuel and corrosive substances, and does not allow severe vibration and bumps. The equipment should be placed in a dry and ventilated place and prevent sunlight, direct and rain.

Contact Person: Summer Sun

Skype: sun.summer_

WhatsApp/Wechat: +8615542318526

Email: lorik @ mingchenggroup.com

Just feel free to contact me for details.