- Product Details

- {{item.text}}

Quick Details

-

Application:

-

Wall plastering

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QK

-

Dimension(L*W*H):

-

1700*700*1200mm

-

Weight:

-

350KG

-

Power:

-

7.5+1.1KW

-

Pulping speed:

-

3m3/h

-

Conveying distance:

-

50m

-

Water-cement ratio of materials used:

-

≤0.4

-

Aggregate size:

-

10mm

-

Work pressure:

-

6-8Mpa

-

Motor Power:

-

7.5+1.1KW

-

Voltage:

-

380V

-

Dimensions:

-

1700*700*1200mm

-

Total Weight:

-

350KG

-

warranty:

-

3 years

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support

-

Certification:

-

CE

Quick Details

-

Max. vertical conveying distance:

-

40M

-

Max. horizontal conveying distance:

-

50M

-

Hopper Capacity:

-

Unlimited

-

Application:

-

Wall plastering

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

QK

-

Dimension(L*W*H):

-

1700*700*1200mm

-

Weight:

-

350KG

-

Power:

-

7.5+1.1KW

-

Pulping speed:

-

3m3/h

-

Conveying distance:

-

50m

-

Water-cement ratio of materials used:

-

≤0.4

-

Aggregate size:

-

10mm

-

Work pressure:

-

6-8Mpa

-

Motor Power:

-

7.5+1.1KW

-

Voltage:

-

380V

-

Dimensions:

-

1700*700*1200mm

-

Total Weight:

-

350KG

-

warranty:

-

3 years

-

After Warranty Service:

-

Video technical support, Online support, Spare parts, Field maintenance and repair service

-

Local Service Location:

-

None

-

After-sales Service Provided:

-

Video technical support, Field installation, commissioning and training, Field maintenance and repair service, Free spare parts, Online support

-

Certification:

-

CE

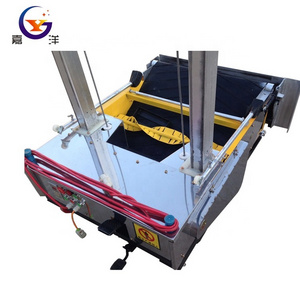

Hot selling high pressure multifunctional cement mortar spraying machine Airless putty wall plastering

Features:

(1) The universal wheel structure is adopted to make the movement more convenient.

(2) Straight-through rotor type non-adhesive material cavity, smooth discharge, high efficiency and time saving.

(3) Four-point elastic compensation compression, good sealing effect, less dust around the machine, and long service life of wearing parts.

(4) Adopting low-pressure and high-speed vortex air conveying to overcome the problems of adhesion, pipe blockage and pulse separation during material conveying, and the material flow is uniform and continuous and stable.

(5) New type spray head, discharge elbow device, improve spraying effect, less rebound, and high spray layer quality.

(6) The use of new anti-sticking cavity and discharge elbow makes cleaning more concise.

(7) Using high-quality wear-resistant liner and high-quality rubber plate, the service life is greatly improved.

| Pulping speed | 3m3/h |

| Conveying distance | 50m |

| Water-cement ratio of materials used | ≤0.4 |

| Aggregate size | 10mm |

| Work pressure | 6-8Mpa |

| Motor Power | 7.5+1.1KW |

| Voltage | 380V |

| Dimensions | 1700*700*1200mm |

| Total Weight | 350KG |

| warranty | 3 years |

Yes. We are one of leading manufacturers

Do youhave Stockproductions to sell?

Yes,ofcourse.Butwe also offer OEM service. Please send us some drawing.

What information do you want to know if i want to get a quotation?

a). The model/size of your products.

b). The application for your products.

c). Special package methods if you needs.

d). Raw material.

Do you inspect the finished products?

Yes.Each step of products will be carried out inspection by QC department until shipping

What advantages do you have?

(1) Punctual: Have your orders met with the latest delivery?

We are a manufacturer with so many advanced and new machines. It ensures we have the ability to carry out the production schedual for punctual delivery.

(2) 20year production experience. We have over 20 years exprerience in this industry.

That means we can preview the problems for the orders and production. Therefore, it will make sure to deduce the risk of bad situation to happen.

(3) Point to point service.

There is two sales departments who will serve you from inquiry to products shipped out. During the process, you just need to discuss with him for all the problems and the way sames much times

1. 24 hours on line service, support Chinese, English, Spanish, French, German, Russian ,technical guidance.

2. When meets machine failure problem, our factory will ensure that the problem is solved within 1 hour.

3. Povide machine install video.

4. Provide logistics information, like shipping by sea, shipping by express DHL, FEDEX delivery, real-time tracking service.

5. If machine is broken ,Non-human causes,the new machine will be provided or new parts will be provided.