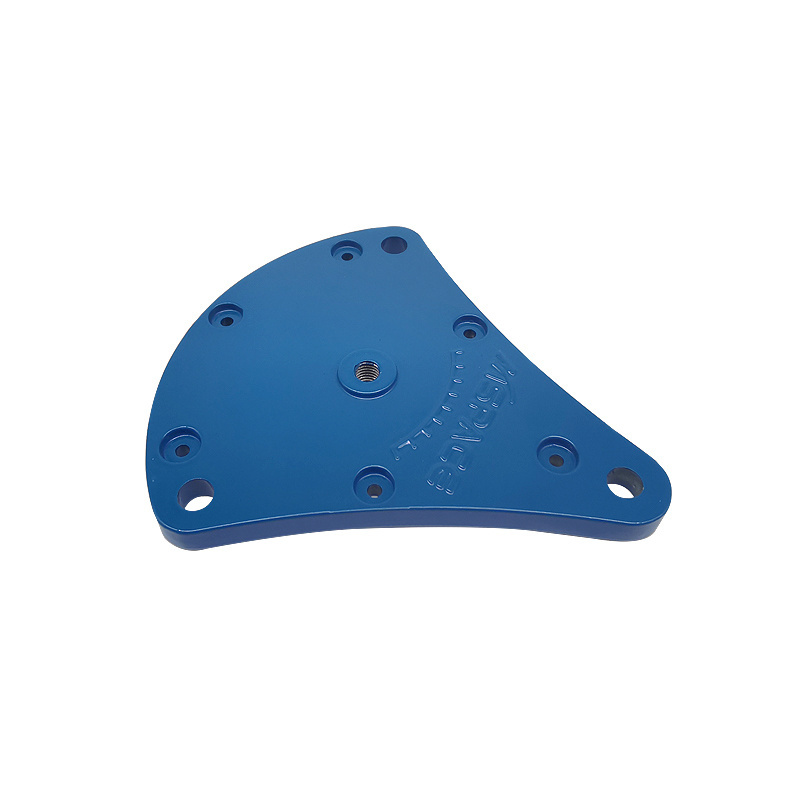

- Product Details

- {{item.text}}

Quick Details

-

Product name:

-

Custom aluminum die casting parts

-

Material:

-

Aluminum, A360,ADC12,A380,ZL101,102,114,etc

-

Tolerance:

-

0.01mm

-

Surface Finish:

-

Polishing, painting, powder coating,sand blasting, electroplating, etc

-

Certification:

-

IATF16949:2016 and ISO16949:2009

-

Quality Control:

-

100% Inspection

-

Service:

-

OEM\ODM

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Longkai

-

Model Number:

-

Longkai-Die Casting Parts

-

Product name:

-

Custom aluminum die casting parts

-

Material:

-

Aluminum, A360,ADC12,A380,ZL101,102,114,etc

-

Tolerance:

-

0.01mm

-

Surface Finish:

-

Polishing, painting, powder coating,sand blasting, electroplating, etc

-

Certification:

-

IATF16949:2016 and ISO16949:2009

-

Quality Control:

-

100% Inspection

-

Service:

-

OEM\ODM

Aluminum Die Casting is a method for creating aluminum parts that are well textured or smooth, and have a good surface finishing, and high dimensional stability. The reasons why aluminum is used for metal casting are as follows:

●It is lightweight and very stable for complex shapes and thin walls.

●It has high thermal and electrical conductivity.

●It has good corrosion resistance.

●It retains its strength at very high temperatures.

Advantages Of Aluminum Die Casting Parts

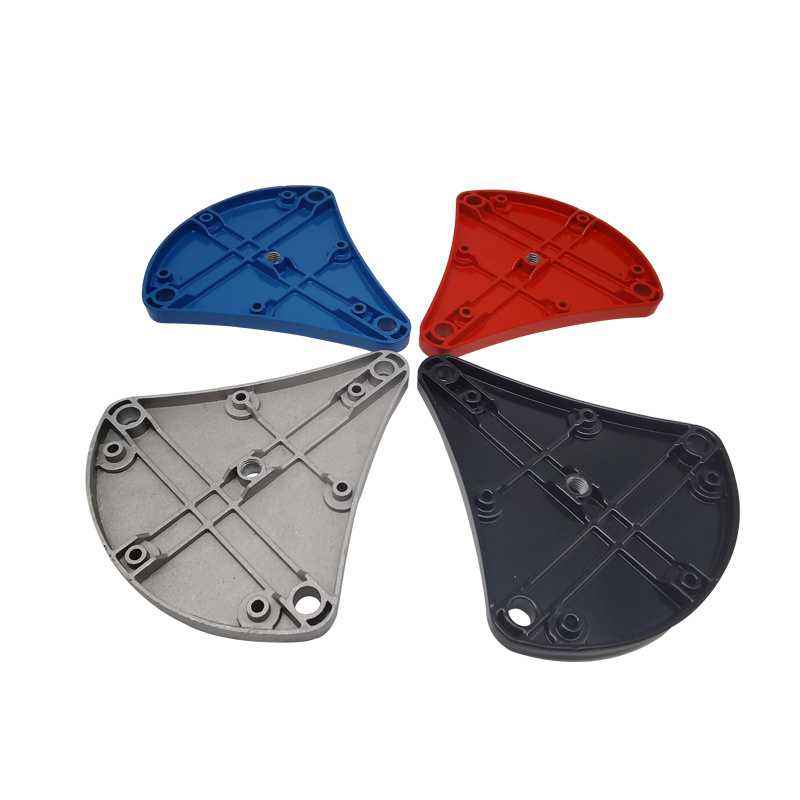

●Aluminum being a lightweight alloy allows making lightweight parts without compromising their strength.

●It has the versatility to produce thin-walled simple or complex-shaped parts with good precision.

●Aluminum cast parts are well textured or smooth depending on the requirements.

●Since the process is very fast, it allows producing tens of thousands of parts in less time and cost.

●This mass production is very cost-effective in contrast to other die casting processes.

●The parts are highly corrosion resistant and are excellent conductors of heat and electricity.

|

Product Name

|

Custom Aluminium Casting Aluminum Die Casting Parts

|

|

|

|

Material

|

Aluminum

|

ADC12,ADC10,A360,A356,A380,A413,B390,EN47100,EN44100 or customized .

|

|

|

|

Zinc

|

ZA3#, ZA5#, ZA8# or customized .

|

|

|

|

Magnesium

|

AZ91D, AM60B or customized .

|

|

|

Surface Treatment

|

Mill Finishing, Anodizing, Powder Coating, Polishing, Brushing, Electrophoresis, Electroplating, Laser Marking, etc.

|

|

|

|

Drawing format

|

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.

|

|

|

Laizhou City Long Kai Casting Co., Ltd. was founded in 2010 and is located in Yantai, Shandong province.We are a professional manufacturer of casting service, specializing in brake disc, brake drum, custom casting part, material can be Steel, Iron, Aluminum, Stainless Steel, Brass etc, . Our factory is certified by IATF16949:2016 and ISO16949:2009.

We provide one-stop custom service from drawing design, rapid prototype, die development, mass production, assemble to delivery.We also have own cnc machining center, providing cnc milling,cnc turning,drilling and cutting service.

We also have aluminum die casting, gravity casting production line and providing different surface finishing options to our customers, having built a strict quality management system according to international standards.

We also have aluminum die casting, gravity casting production line and providing different surface finishing options to our customers, having built a strict quality management system according to international standards.

● 100% Factory Outlet

We have our own casting factory, the integration of production and trade, the price and quality are better than 90% of the suppliers.

● Rich customization experience

We have served 100+ customized customers, and we can provide clients with fast, accurate and effective customized solution, both full customization and design-based customization are available.

●Powerful Manufacturing Capabilities

We have automatic production lines, CNC machining centers and surface treatment workshops, which work together to provide technical support for mass production.

● 24h Online Service

Reply within 1 hour, send quotation within 6 hours, and provide customized solutions within 12 hours.

Q: Are you trading company or manufacturer ?

A:We are a professional manufacturer with over 10 years of experience in the custom casting parts.

Q: Do you accept customized orders?

A: Yes.OEM and ODM orders are highly welcome.

Q: What's the delivery time?

A: About 20-25 days after receipt of deposit.

Q: Can you accept mould making?

A: Yes, we can provide mould making and die development.

Hot Searches