- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Wodon

-

Application:

-

bimetal plate for crusher liner

-

Width:

-

1400mm, 1500mm, 2000mm, 2100mm, customized

-

Length:

-

3000mm, 3400mm, 3500mm, customized

-

Hardness:

-

55 - 65 HRC

-

Flatness tolerance:

-

±3mm/m

-

Overlay thickness tolerance:

-

0-0.5mm

-

Microstructure content:

-

Cr7C3 volume fraction over 50%

-

Material:

-

Q235, Q345, SS400, C, Cr, Mo etc

-

Chemical Composition:

-

C: 3-5%, Cr: 25-40%, Mn: 1-3%, Si:1-3%, Fe: balance

-

Impact resistance:

-

Medium

-

Model Number:

-

WD1000,WD1100,WD1200, WD1500,WD1600,WD1800,WDNC100

-

Technique:

-

Hardfacing, open arc welding, submerged arc welding

Quick Details

-

Type:

-

Steel Sheet

-

Standard:

-

AiSi

-

Grade:

-

chromium carbide overlay plate

-

Place of Origin:

-

Tianjin, China

-

Brand Name:

-

Wodon

-

Application:

-

bimetal plate for crusher liner

-

Width:

-

1400mm, 1500mm, 2000mm, 2100mm, customized

-

Length:

-

3000mm, 3400mm, 3500mm, customized

-

Hardness:

-

55 - 65 HRC

-

Flatness tolerance:

-

±3mm/m

-

Overlay thickness tolerance:

-

0-0.5mm

-

Microstructure content:

-

Cr7C3 volume fraction over 50%

-

Material:

-

Q235, Q345, SS400, C, Cr, Mo etc

-

Chemical Composition:

-

C: 3-5%, Cr: 25-40%, Mn: 1-3%, Si:1-3%, Fe: balance

-

Impact resistance:

-

Medium

-

Model Number:

-

WD1000,WD1100,WD1200, WD1500,WD1600,WD1800,WDNC100

-

Technique:

-

Hardfacing, open arc welding, submerged arc welding

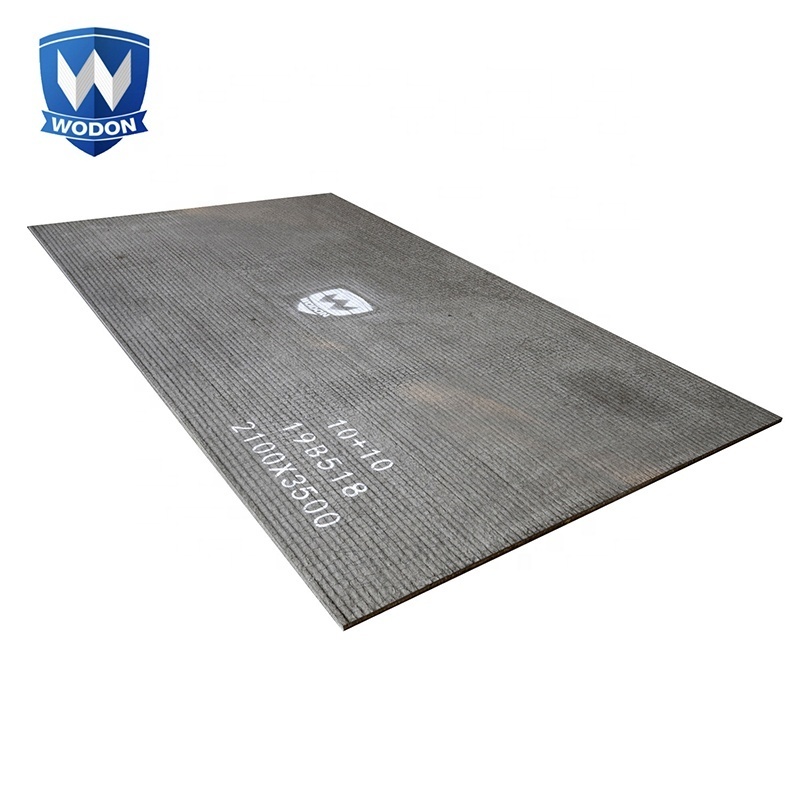

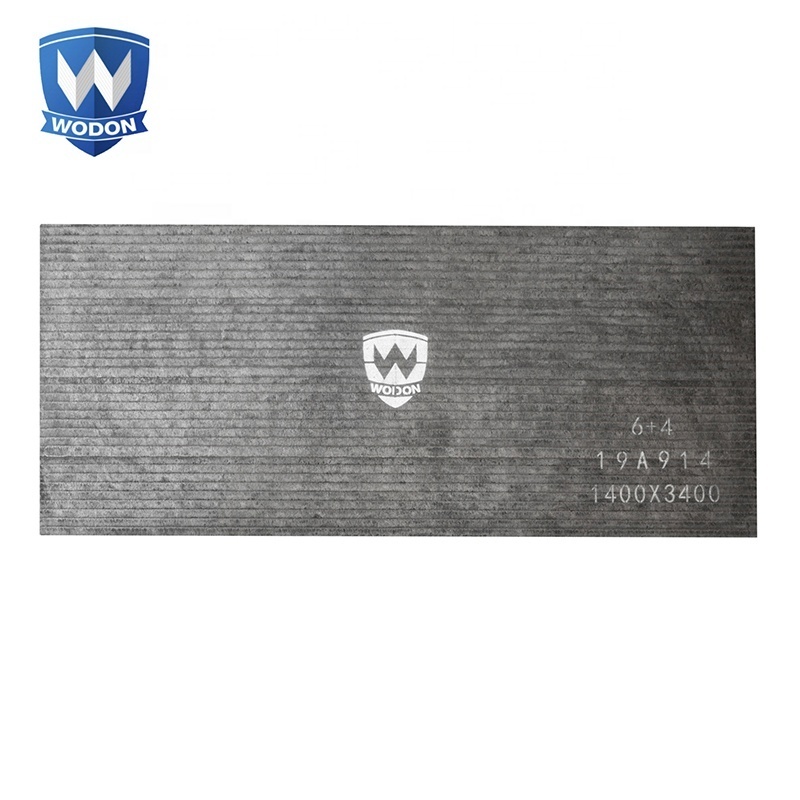

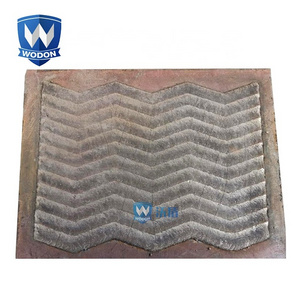

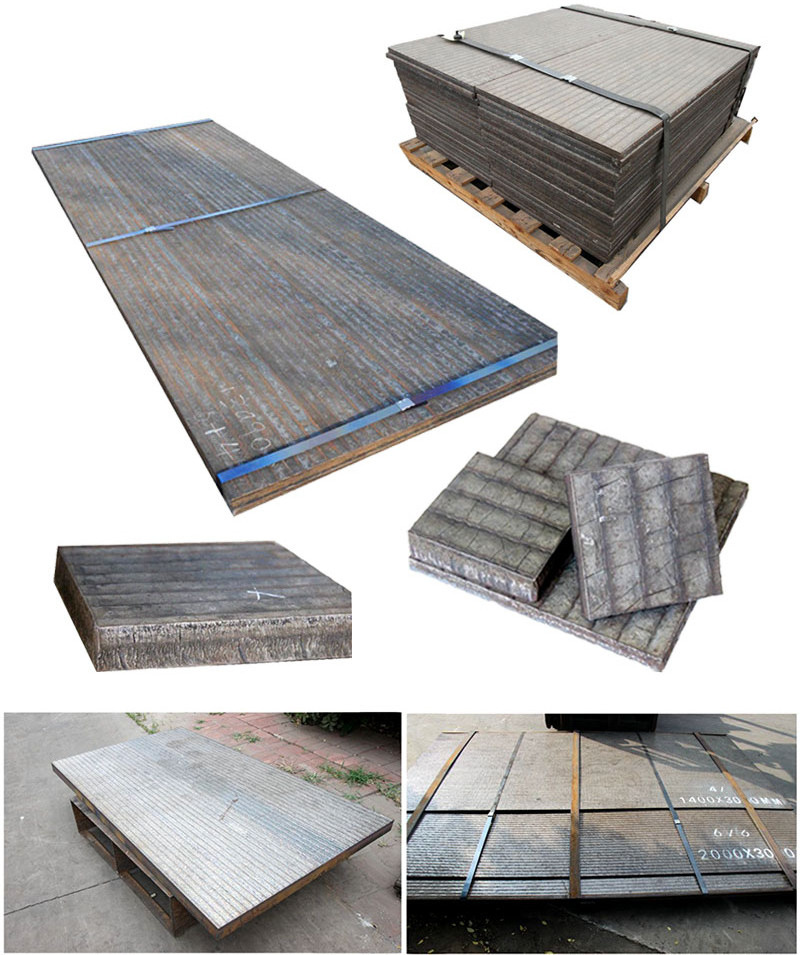

High abrasion hardfacing bimetal wear resistant compound steel plate sheet

Wodon hardfacing bimetal wear resistant compound sheets chromium carbide overlay steel plate

Wodon wear plates are manufactured by welding one or multiple wear resistant layers on a medium or low carbon steel base plate.The overlay alloy has a high amount of chromium carbide hard particles which makes the plate have good wear and impact resistance.

Overlay thickness range: 3- 50 mm

Wear plate size (mm) : 1400*3000, 1400*3400, 1400*3500,

1500*3000, 2000*3000, 2100*3500,

others on request

c

Chromium Carbide Overlay Wear Plates

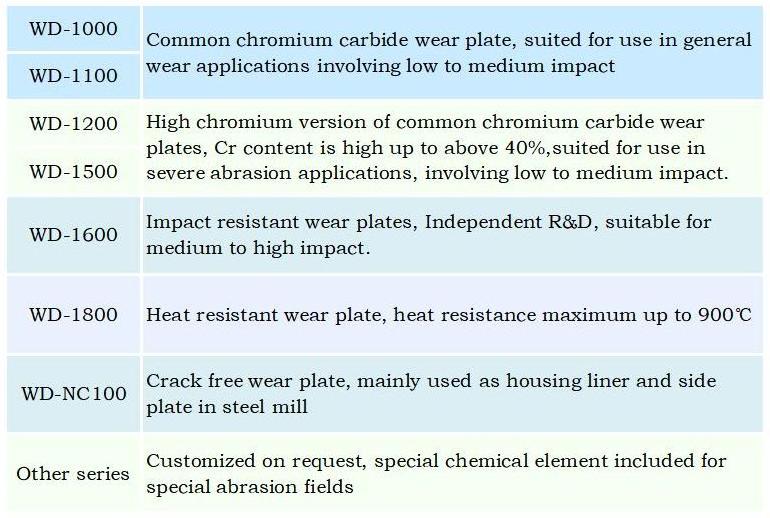

| Model | Characteristics | Hardness | Chemical Composition (%) | Operating Temperature | ||||||

| (HRC) | C | Cr | Mn | Si | Mo+Nb | Ni+V+W | Fe | |||

| WD-1000 | Common chromium carbide wear plate, suited for use in general wear applications involving low to medium impact | 58-65 | 3.0-5.0 | 17.0-27.0 | 1.0-3.0 | 1.0-3.0 | / | / | Bal. | <400℃ |

| WD-1100 | ||||||||||

| WD-1200 | High chromium carbide wear plates, Cr content is high up to above 40%,suited for use in severe abrasion applications, involving low to medium impact. | 58-65 | 3.0-6.0 | 25.0-45.0 | 1.0-3.0 | 1.0-3.0 | / | / | Bal. | <400℃ |

| WD-1500 | ||||||||||

| WD-1600 | Impact resistant wear plates, Independent R&D, suitable for medium to high impact. | 58-65 | 3.5-6.5 | 25.0-45.0 | 1.0-3.0 | 1.0-3.0 | * | / | Bal. | <600℃ |

| WD-1800 | Heat resistant wear plate, heat resistance maximum up to 900℃ | 58-65 | 4.0-7.0 | 25.0-40.0 | / | / | * | * | Bal. | <900℃ |

| WD-NC100 | Crack free wear plate, mainly used as housing liner and side plate in steel mill | 50-55 | ||||||||

| Other series | Customized on request, special chemical element included for special abrasion fields | / | ||||||||

| Sheet size: 1400*3400mm 1400*3000mm 1500*3000mm 1400*3500mm 2000*3000mm 2100*3500mm Other on request | ||||||||||

| Base metal material: Q235, Q345 and so on. | ||||||||||

| Overlayer thickness: 3-50mm | ||||||||||