- Product Details

- {{item.text}}

Quick Details

-

Power:

-

custimized

-

Dimension(L*W*H):

-

custimized

-

Weight:

-

200 KG

-

Material:

-

SUS304/SUS316/red Copper

-

Name:

-

1500L brewhouse beer brewing equipment

-

Keywords:

-

Beer Equipment

-

Function:

-

Brewing Beer Brewing Equipment

-

Capacity:

-

1500L per capacity

-

Thickness:

-

Inner:3mm Outside:2mm

-

Control system:

-

PLC

-

Polishing:

-

Mirror Polishing

-

Application:

-

Brewery

-

Volume:

-

100L-30000L

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

Tonsen

-

Voltage:

-

custimized

-

Power:

-

custimized

-

Dimension(L*W*H):

-

custimized

-

Weight:

-

200 KG

-

Material:

-

SUS304/SUS316/red Copper

-

Name:

-

1500L brewhouse beer brewing equipment

-

Keywords:

-

Beer Equipment

-

Function:

-

Brewing Beer Brewing Equipment

-

Capacity:

-

1500L per capacity

-

Thickness:

-

Inner:3mm Outside:2mm

-

Control system:

-

PLC

-

Polishing:

-

Mirror Polishing

-

Application:

-

Brewery

-

Volume:

-

100L-30000L

exchanger, centrifugal pump, control cabinet, pipeline, valves and so on.

This system design uses the advanced German design concept, materials are all SUS304, plank with posco plate, using TIG welding

argon arc welding, control adopts Siemens PLC control, valve adopts pneumatic valve, can realize automatic control.

This system features: small footprint, high production efficiency, easy to operate.

|

Capacity/batch

|

100L

|

200L

|

300L

|

500L

|

1000L

|

|

Model

|

TS-100L

|

TS-200L

|

TS-300L

|

TS-500L

|

TS-1000L

|

|

Area

|

15M2

|

25M2

|

35M2

|

45M2

|

80M2

|

|

Power

|

8kw

|

12kw

|

20kw

|

35kw

|

35/15kw

|

|

Frementation cycle

|

8~20days

|

8~20days

|

8~20days

|

8~20days

|

8~20days

|

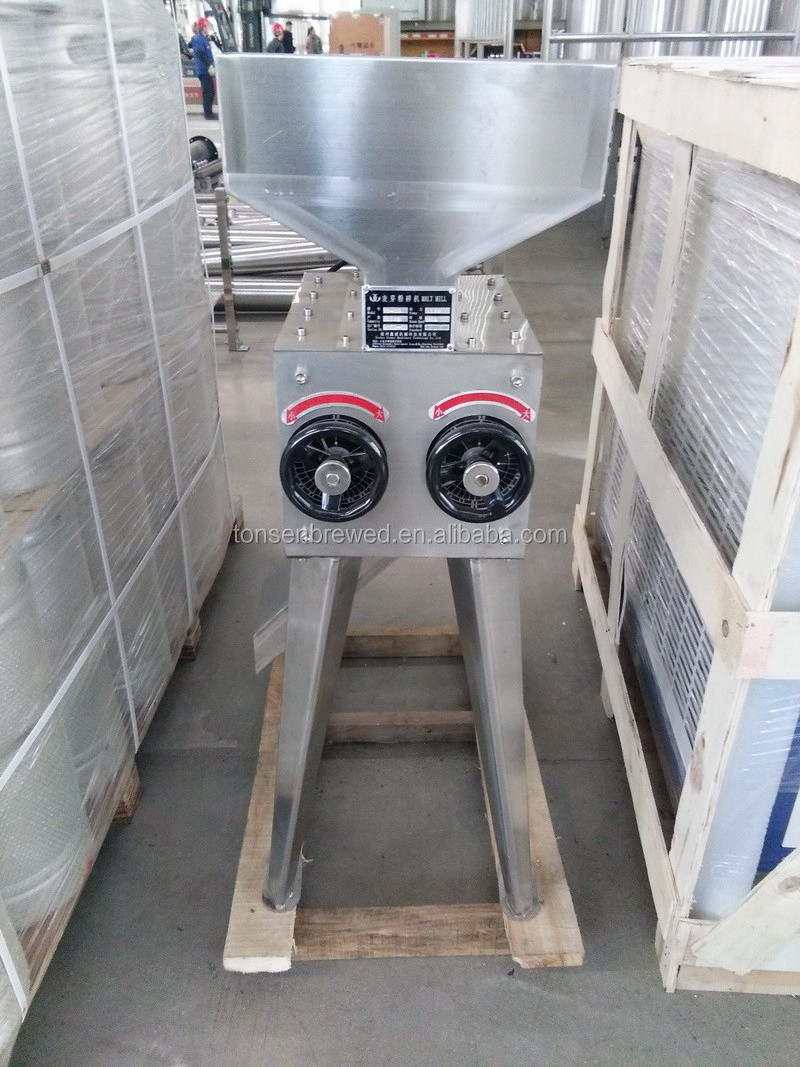

1----Milling system

2----Brew House System

-Capacity 100L-5000L, 1bbl-40bbl.

- Steam heated, electrical heated or natural gas

-Mash tun with mixer, steam jacket, VFD motor, insulated 80mm. Stainelsss steel 304.

-Lauter tun with rake system, milled false bottom, sparging spray ring,VFD motor, insulated 80mm.

-Boiling kettle with steam jacket, inner heated option, insulated 80mm. Stainelsss steel 304.

-Whirlpool with Tangential whirlpool inlet. insulated 80mm. Stainelsss steel 304.

-Insulated HLT and CLT with the pipelines and pumps

-External grant, hops back, heat exchanger.Wort oxygenation system, working platform.

-All the necessary pipelines and pumps

3--- -Fermenter&BBT System

-Interior shell thickness 3-6mm, Exterior shell=2mm

-100% TIG welding with pure argon gas shield

-Interior finish: pickled and passivated, external polished, 80mm insulated

-Test pressure 3 bar, working pressure 1.5 bar

-Glycol zones (Both on side and concial/bottom)

-60°conical bottom for Fermener, Shadow less side man way

-Racking arm, Sample valve, Pressure relief valve on the top, Dry hopping on the top

-Mechanical relief valve 3 bar on CIP arm with pressure gauge

4.----Cooling System

Description: Air type chiller + Ice water tank or Glycol tank

Capacity: 3HP, 5HP, 7HP, 10HP, 15HP, 20HP, 30HP+ 500L-20000L tank

Brand: Copeland, SANYO

5----Control System

-PID or PLC system

-SIEMENS program S7-200, Siemens touch screen.

-Penumatic valves for optional

5----Canning line, Kegging line

-Double station Kegging line.

-Small capacity Canning line.

Jinan Tonsen Equipment Co., Ltd. is an international comprehensive enterprise specializing in R&D,production,technical support and services for beer equipment and wine equipment .

We provide complete beer brewing solutions that include: malt handling system, brew house system, beer fermenting/storage system, cooling system, cleaning system, control system, package line.

Tonsen brewing equipment has been exported to more than 30 countries, which include USA, Canada, Australia, Japan, UK, France, Germany, Denmark,Norway,Agentina,Russia etc.

1) All tanks will be packed with soft protection material and mounted on steel frame

2) All accessories and spare parts will be packed with soft protection material and then put into iron box

3) After loaded into containers, all equipment will be fixed to the containers.

FAQ

A: Yes,we have been in providing the professional products in this field for 15 years.

2.Ask:how to install the machine ?

Answer:we can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you

to install it in your country .

3.Q :How you pack the products ?

A: Normally as the export standard packaging or as you required.

4.Q: What is your available port of shipment?

A:Qingdao port,shanghai etc.

5.Q: Is customized available ?

A: Yes, according to your detailed drawings you provide

6.Q:Ask:how to install the machine ?

Answer:we can intrust the install the machine by vedio, email ,picture.....if large project , we can arrange the worker help you

to install it in your country .

7.Q:After Sale Service

1. Warranty policy three years from shipment

2. We will send you the replacement after received the broken part

8.Q: Are you trading company or manufacturer ?

A: We are factory and welcome to visit us at any time.

9.Q: How long is your delivery time?

A: Generally single tanks need 20-30 days, for whole plant need 40-50days.

10.Q: Do you have CE and UL certification?

A: Yes.

11.Q: What is your terms of payment ?

A: 50% deposit and 50% before delivery.