- Product Details

- {{item.text}}

Quick Details

-

Material:

-

Wooden package, Carbon Steel

-

Weight:

-

Depends on capacity

-

Size:

-

Depends on capacity

-

Power:

-

0.5~5.5, 1.5-30kw

-

Weight (KG):

-

500 kg

-

Product name:

-

Water Filter

-

Application:

-

Water Purification

-

After-sales Service Provided:

-

Video Technical Support\Online Support

-

Brand:

-

Longdai

-

Control:

-

Fully Automatic Control

-

Operation:

-

Easy Handling

-

Flow rate:

-

customized

Quick Details

-

Marketing Type:

-

Hot Product 2023

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Longdai

-

Material:

-

Wooden package, Carbon Steel

-

Weight:

-

Depends on capacity

-

Size:

-

Depends on capacity

-

Power:

-

0.5~5.5, 1.5-30kw

-

Weight (KG):

-

500 kg

-

Product name:

-

Water Filter

-

Application:

-

Water Purification

-

After-sales Service Provided:

-

Video Technical Support\Online Support

-

Brand:

-

Longdai

-

Control:

-

Fully Automatic Control

-

Operation:

-

Easy Handling

-

Flow rate:

-

customized

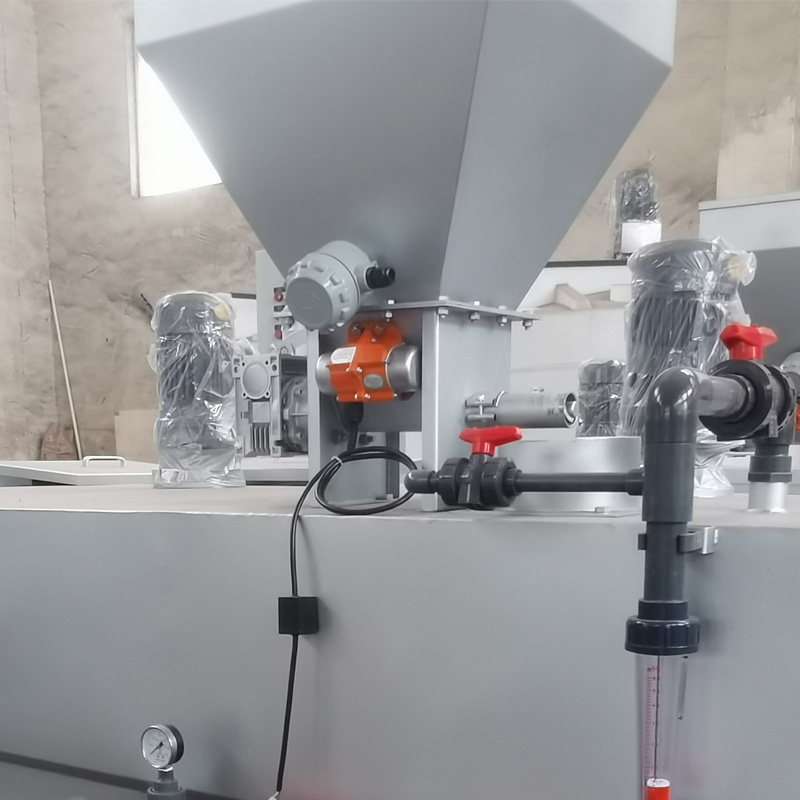

Product Description

The use of chemicals in various industries has become a necessity for efficient and effective processing. Whether it be for water treatment, food processing, or pharmaceutical manufacturing, chemical dosing is an essential aspect of these industries. Proper chemical dosing is necessary to ensure the desired results and prevent negative impacts on the environment and public health. In this context, chemical dosing equipment plays a critical role in the operation of these industries. This equipment is designed and created to deliver accurate and consistent amounts of chemicals to the processing system. The equipment's primary function is to facilitate the controlled and appropriate dilution and delivery of a chemical, regardless of application or industry.

Product Features

1. Highly integrated integrated equipment;

2. Fully automatic control function;

3. The equipment is small in size, simple in operation and convenient in installation. Only water and power are needed on site;

4. The liquid medicine mixer is made of stainless steel, and the dissolution effect is 100%;

5. Safe and reliable operation and stable performance;

6. It has good corrosion resistance and is made of engineering plastics and stainless steel in contact with the medium;

7. It is not only suitable for powder, fiber, materials that are difficult to dissolve, easy to agglomerate, and materials with high feeding requirements, but also suitable for the configuration and feeding of liquid materials;

8. High efficiency stainless steel special deceleration mixer to prevent macromolecular chain from breaking;

2. Fully automatic control function;

3. The equipment is small in size, simple in operation and convenient in installation. Only water and power are needed on site;

4. The liquid medicine mixer is made of stainless steel, and the dissolution effect is 100%;

5. Safe and reliable operation and stable performance;

6. It has good corrosion resistance and is made of engineering plastics and stainless steel in contact with the medium;

7. It is not only suitable for powder, fiber, materials that are difficult to dissolve, easy to agglomerate, and materials with high feeding requirements, but also suitable for the configuration and feeding of liquid materials;

8. High efficiency stainless steel special deceleration mixer to prevent macromolecular chain from breaking;

Classification

The type of system chosen may depend on the specific needs of the industry or application. For example, water treatment plants can use a different batching system than coating manufacturers. The required dosing equipment for precise and accurate chemical dosing will depend on the materials used, their viscosity, and the required delivery rate.

There are two main types of dosing systems: volumetric and gravimetric. The volume measurement system distributes chemicals based on volume, while the weight measurement system distributes chemicals based on weight. In most industries, volumetric feeding systems are used because they are easier to use and more practical in control, measurement, and automation. However, in industries that require precise drug delivery, such as pharmaceutical manufacturing or applications where any minor changes may significantly alter the product, weight delivery systems are preferred.

Parameters

|

Type

|

Unit

|

JY-400

|

JY-1000

|

JY-2000

|

JY-4000

|

JY-8000

|

|

Preparation capacity

|

L/H

|

400

|

1000

|

2000

|

4000

|

8000

|

|

Dilution water consumption

|

L/H

|

1500

|

1500

|

3000

|

6000

|

12000

|

|

Dilution water pressure

|

Bar

|

1.3-29

|

1.3-29

|

1.3-29

|

6-132

|

12-264

|

|

long

|

mm

|

1770

|

2410

|

2070

|

3181

|

4434

|

|

wide

|

mm

|

915

|

950

|

1090

|

1521

|

1910

|

|

high

|

mm

|

1250

|

1605

|

1755

|

2263

|

2350

|

|

Connection size of water inlet pipe

|

DN

|

1''

|

1''

|

1''

|

2''

|

2''

|

|

Connection size of discharge pipe

|

DN

|

25

|

25

|

32

|

40

|

50

|

|

Power

|

kw

|

1.5

|

2.6

|

3.2

|

5.0

|

9.5

|

Real picture

Hot Searches