- Product Details

- {{item.text}}

Quick Details

-

Cabinet inner worksize::

-

Diameter 400mm * Length 650mm

-

Machine Lighting:

-

220V50HZ

-

Power Supply:

-

380V 50HZ

-

Abrasive flow rate::

-

60kg/min

-

Impeller type::

-

Double-disc

-

Impeller head power::

-

4.0KW

-

Belt drive motor::

-

0.75KW

-

Dust removal system fan motor::

-

1.5KW

-

Shot lifting system::

-

0.75KW

-

Roller belt drive motor::

-

0.75KW

Quick Details

-

Place of Origin:

-

China

-

Brand Name:

-

KAFAN

-

Weight (KG):

-

300 KG

-

Cabinet inner worksize::

-

Diameter 400mm * Length 650mm

-

Machine Lighting:

-

220V50HZ

-

Power Supply:

-

380V 50HZ

-

Abrasive flow rate::

-

60kg/min

-

Impeller type::

-

Double-disc

-

Impeller head power::

-

4.0KW

-

Belt drive motor::

-

0.75KW

-

Dust removal system fan motor::

-

1.5KW

-

Shot lifting system::

-

0.75KW

-

Roller belt drive motor::

-

0.75KW

Products Description

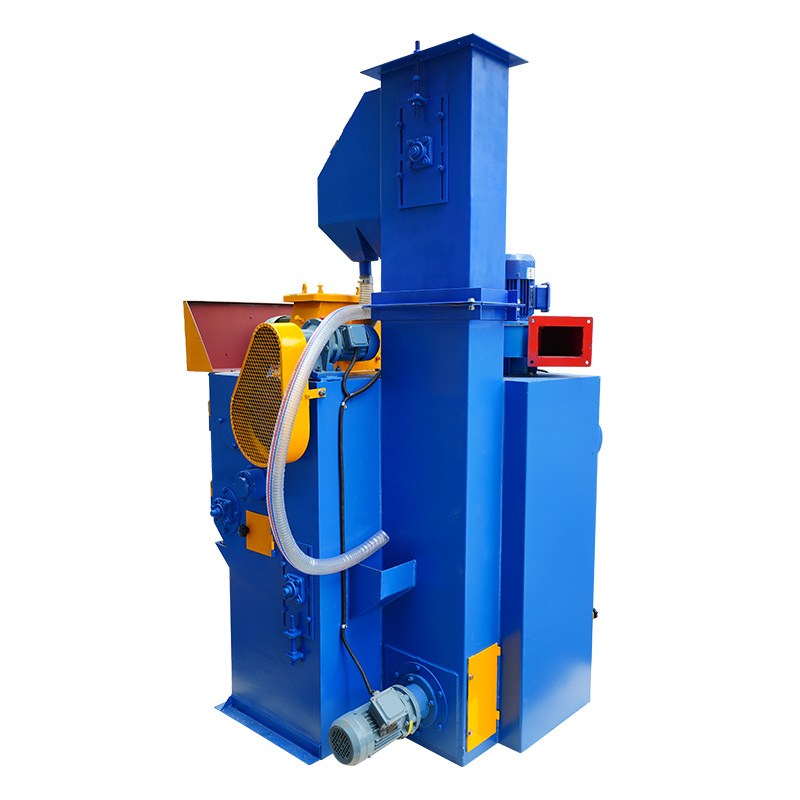

Airless steel shot blaster automatic shot blasting machine for auto parts

This shot blaster is suitable for surface cleaning and strengthening of medium or small size castings, forge pieces, auto parts and a variety of hardware.

Rubber continuous belt shot blasting clean-up machine has advantages of advanced design, rational construction, low-power.

It is for different production capacity, the machine can be used not only as a single machine, but also as a part of a line.

Working principle of the a

irless steel shot blaster

The shot blasting machine is not powered by compressed air, but is powered by an electromechanical shot blasting machine, and uses the high-speed projectile thrown by the shot blasting machine to clean or strengthen the surface of the metal workpiece.

Details Images

Airless steel shot blaster for auto parts features

1. Uniquelly designed with double-disc impeller for high-flow and high-speed projectile throwing, it is directly driven by a reliable electric motor with long service life.

2. Configured a pulse filter cartridge for dust removal system, features high removal efficiency and requires easy installation and maintenance.

2. Configured a pulse filter cartridge for dust removal system, features high removal efficiency and requires easy installation and maintenance.

3. The shot blasting chamber is steel and plate riveted welding structure and laid with alloy guard plates, all peform wear-resistant, impact-resistant and long lifespan.

4. Equipped with safety protection devices to ensure safe and effective work, and

can be equipped with automatic filling and automatic emptying systems.

5. Each shot blasting machine can be customized and manufactured depending on the size, weight and daily number of parts to be blasted.

Shot Blasting Chamber

Motor

Dust Filter Element

Electrical Control Box

Product Paramenters

|

Model

|

KF-S4065

|

|

Cabinet inner worksize:

|

Diameter 400mm * Length 650mm

|

|

Impeller type:

|

Double-disc

|

|

Impeller head power:

|

4.0KW

|

|

Roller belt drive motor:

|

0.75KW

|

|

Dust removal system fan motor:

|

1.5KW

|

|

Shot lifting system:

|

0.75KW

|

|

Abrasive flow rate:

|

60kg/min

|

|

Voltage:

|

380V 50HZ

|

Application

Rubber belt shot blaster is good application for high volumes of small components. Components are gently tumbled at constant speed under an electric powered shot stream on a perforated abrasion resistant rubber belt.

Recommend Products

Product packaging

Hot Searches