- Product Details

- {{item.text}}

Quick Details

-

Raw material:

-

various E-waste material

-

Capacity:

-

based on customer requirement

-

Function:

-

Separate Copper, etc metal

-

Machinery Type:

-

fully-automatic

-

Keywords:

-

Pcb Copper Recycle, precious metal refining machine, etc

-

Color:

-

can customized

-

Certification:

-

CE ISO,etc

-

Advantage:

-

High Efficiecny

-

Keyword:

-

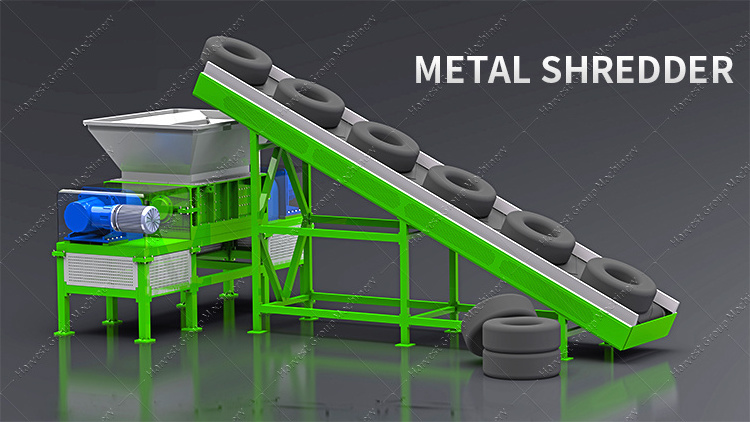

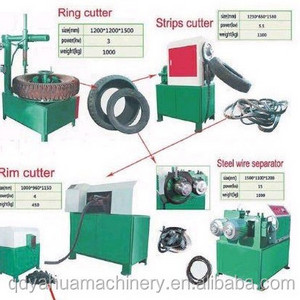

Tire Shredder Rubber Crusher

-

Application:

-

Waste Tire Processing Machinery

Quick Details

-

Place of Origin:

-

China

-

Power (kW):

-

315 kW

-

Weight (KG):

-

2400 KG

-

Raw material:

-

various E-waste material

-

Capacity:

-

based on customer requirement

-

Function:

-

Separate Copper, etc metal

-

Machinery Type:

-

fully-automatic

-

Keywords:

-

Pcb Copper Recycle, precious metal refining machine, etc

-

Color:

-

can customized

-

Certification:

-

CE ISO,etc

-

Advantage:

-

High Efficiecny

-

Keyword:

-

Tire Shredder Rubber Crusher

-

Application:

-

Waste Tire Processing Machinery

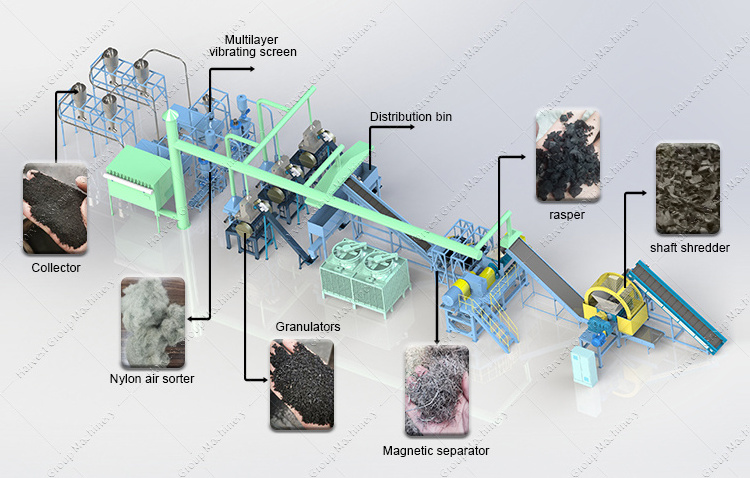

Product brief introduction

The rasper is specially designed for tire secondaryshred and steel separation. lt can process and produce 10-30mm wire freechips, the steel wire will be separated by rasperand attracted by magnet. The rasper blades are D2 steel, made from bestquality steel and heat treated by bodycote foroptimal shredding performance.The capacity forrasper ranges from 300kg to 6000kg per hour.

Advantage

1.High inertia from the flywheel ensures an even load on the machine, thus yielding a higher cutting power.

2.The machine is designed for quick and easy change of knives and screens, which are available in different hole sizes for flexible production.

3.The blades can be changed upside down, so both sides will be applied for cutting, thus will greatly increase the blade life.

4.The knives are processed by many steps, and can be reground multiple times on a “flat-bed&rdq

Rubber crusheris used to grind the chunks into smaller mesh powder through the vibrating screen as you need.

| Model | Drum diameter | Drum length | Roll speed ratio | Motor power |

| XKP-350 | 300mm | 500mm | 1:2.5 | 30KW |

| XKP-400 | 400mm | 600mm | 1:2.5 | 45KW |

| XKP-450 | 450mm | 760mm | 1:2.5 | 55KW |

| XKP-560 | 560mm | 800mm | 1:2.5 | 75KW |

| XKP-560D | 300mm | 1000mm | 1:2.5 | 132KW |

Waste Tire Recycling Rubber Powder Machine is suitable for different kinds of scrap tires, and we can provide you the best solution based on your different tires.

shred whole tires into 50*50mm/60*60mm rubber blocks.Host equipment,rubber crusher: is used to be grind the chunks into small mesh powder through

the vibrating screen as you need.

crumb rubber is ground down into a clean powder form with virtually all steel and fiber removed.Rubber powder has numerous secondary uses from injection molding products,coatings,roofing materials and various asphaltapplications.

Waste Tire Recycling Rubber Granule Making Machine is adopting physical recycling method and is designed to grind the rubber mulch from the rasper into small granules as fine as 1-6mm. The granules are screened and re-circulated until the desired size is reached.

Rubber powder is the final result of ambient tire recycling.At this stage,crumb rubber is ground down into a clean powder form with virtually all steel and fiber removed.Rubber powder has numerous secondary uses from injection molding products,coatings,roofing materials and various asphaltapplications.

Rubber Granules System

At this stage,wire-free rubber mulch is processed into a uniform granule with all steel and fiber removed.Crumb Rubber is typically found in 3/8”- 400 microns (0.400 mm) in size.

Rubber Powder System

At this stage, crumb rubber is ground down into a clean powder form with virtually all steel and fiber removed.

Rubber Powder is typically found in 400- 74 microns in size.

Q1: Are you a factory or a trading company ?

A1: We are a manufacturer with 30 years production experience in tire recycling plant and nail making machines. We have export license, we can offer you the factory prices.

Q2: Can you guarantee the capacity as you mentioned ?

A2: Definitely yes, the grooved two rollers are specially designed to increase the output and ensure the working efficient.

Q3: are you sure the final rubber powder can be completely clean out of wire steel or nylon ?

A3: The final powder purity can reach 99.9%. we have magnetic separator which can separate the wire steel from the rubber powder.