- Product Details

- {{item.text}}

Quick Details

-

Roll Ratio(Front/Back):

-

1:1.27

-

Cooling Mode:

-

Circulating Water

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SFC

-

Voltage:

-

as customized

-

Dimension(L*W*H):

-

4350*1850*1785mm

-

Year:

-

customized

-

Power (kW):

-

37

-

Weight (KG):

-

4000 KG

-

Type:

-

Open Mixing Mill

-

Lubrication Type:

-

Automatic Thin Oil Lubrication

-

Control System:

-

PLC

-

Friction Ratio:

-

1:1.17

-

Working Length:

-

2000mm / 79inch

-

HS code:

-

84778000

-

Front rolle linear speed:

-

28.42 m/min

-

Roller Material:

-

Chilled cast iron

-

Drive way:

-

single or double axis

-

Wechat / Whatspp:

-

+86-18253286958

Quick Details

-

Diameter of Roll(mm):

-

400 mm

-

Rotation Speed of Front Roll(rpm):

-

16 - 20 rpm

-

Length of Roll(mm):

-

1000 mm

-

Roll Ratio(Front/Back):

-

1:1.27

-

Cooling Mode:

-

Circulating Water

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

SFC

-

Voltage:

-

as customized

-

Dimension(L*W*H):

-

4350*1850*1785mm

-

Year:

-

customized

-

Power (kW):

-

37

-

Weight (KG):

-

4000 KG

-

Type:

-

Open Mixing Mill

-

Lubrication Type:

-

Automatic Thin Oil Lubrication

-

Control System:

-

PLC

-

Friction Ratio:

-

1:1.17

-

Working Length:

-

2000mm / 79inch

-

HS code:

-

84778000

-

Front rolle linear speed:

-

28.42 m/min

-

Roller Material:

-

Chilled cast iron

-

Drive way:

-

single or double axis

-

Wechat / Whatspp:

-

+86-18253286958

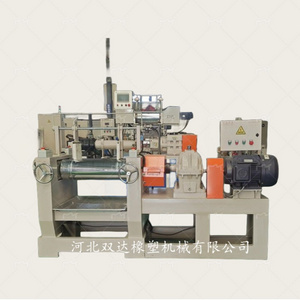

Two Roll Mixing Mill for Mixing Rubber Materials / Rubber Mixing Machine / Rubber Mixer

1. Rolls: Chilled Alloy Cast Iron rolls with surface hardness 68~72HS. The Rolls are mirror finished & polished, duly grinded and are hollowed for cooling or heating.

2. Roll Clearance Adjusting Unit: Nip adjustment at two roller ends is done manually using two separate screws attached to the brass housing body.

3. Roll Cooling: Universal Rotary joints with inner Spray pipes with Hoses and Headers. Piping is complete up to supply pipe terminal.

4. Journal Bearing Housing: Heavy Duty Steel Casting Housing fitted with Anti Friction Roller Bearings.

5. Lubrication: Full Automatic Grease lubrication pump for Anti Friction Roller Bearings fitted in dust sealed housing.

6. Stand Frame & Apron: Heavy Duty Steel Casting.

7. Gearbox: Hard-tooth reduction gearbox, GuoMao brand.

8. Base Frame: Common base frame heavy duty, Steel channel and MS plate fabricated accurately machined on which whole machine with Gearbox and motor are fitted.

9. Electric Panel: Star Delta Electric operating panel with Auto Reversing, Voltmeter, Ampere, Overload protection relay, 3 Phase Indicator and Emergency Stop Switch.

We can design various kinds of non-standard rubber machinery according to your requirements.

RFQ:

1. What does your factory do regarding quality control?

We pay much more importance to quality control from the very beginning to the end of production. Every machine will be fully assembled and carefully tested before shipment.

2. What's the machine quality guarantee?

Quality guarantee time is one year.We choose world famous brand components to keep our machine in perfect working condition.

3. Are you able to give installation and commissioning overseas?How long time will it take?

Yes, we can supply overseas service and technical support but customer needs to pay for the cost of the installation. Small machine usually takes within 2~3 days. Big production line usually takes about 30 days.

4. How can I trust you to deliver the right machine as I ordered?

We will absolutely deliver a good quality machine as we discussed and confirmed in the order. The core of our company culture is innovation,quality,integrity and efficiency. Also we have had many good cooperation with world famous rubber production manufacturers.

5. How can we go to your side?

We are located in Qingdao City, Shandong province, China. The name of airport is Qingdao liuting airport. We will pick up you at the airport

.

https://www.alibaba.com/product-detail/Superior-Quality-Rubber-Kneader-Machine-with_1600069203601.html?spm=a2747.manage.0.0.4bf871d2QA1Zji https://www.alibaba.com/product-detail/Hot-Sale-Rubber-Curing-Press-Machine_62292957968.html?spm=a2747.manage.0.0.4bf871d2QA1Zji