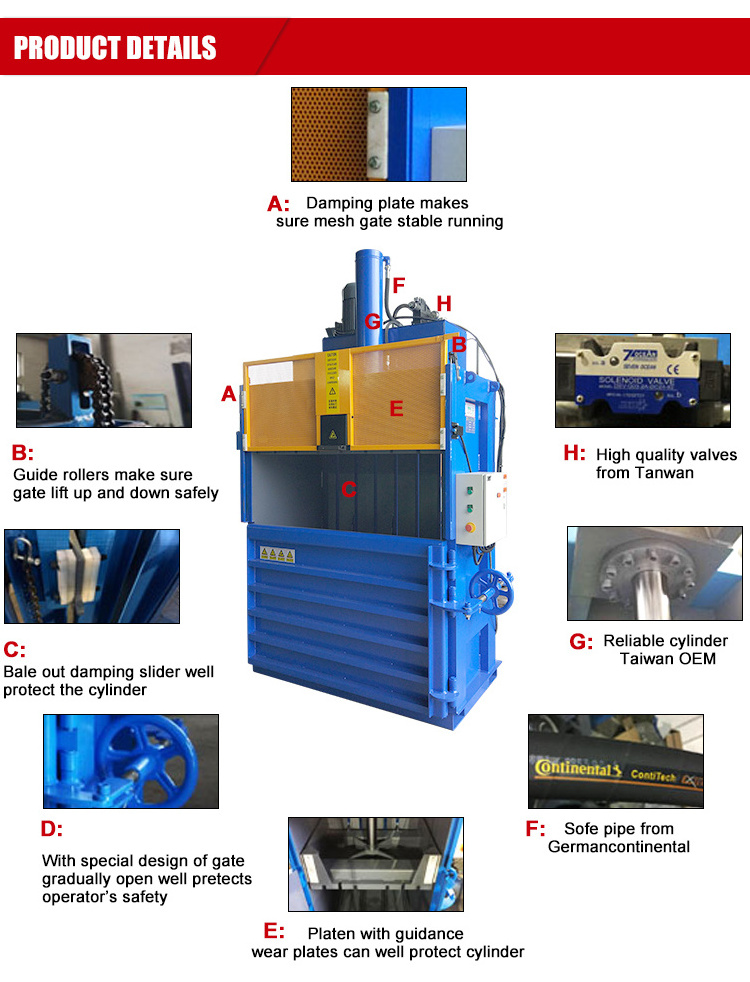

- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

XTPACK BALER

-

Weight:

-

7 KG

-

Dimension(L*W*H):

-

3734*1098*3700mm

-

Product name:

-

Tire balers

-

Baling Chamber Size:

-

1530*790*1800mm

-

Bale size(L*W*H)After expansion:

-

1600*850*1200mm

-

Bale weight:

-

1tons

-

Usage:

-

Specially designed for compressing rubber products like tires etc

-

Bale size*(L*W*H,H is adjustable):

-

1530*790*(1500-1200)mm

-

After Warranty Service:

-

Online support,Engineers available to service machinery overseas

-

Local Service Location:

-

India,Japan

-

Certification:

-

CE ISO

Quick Details

-

Voltage:

-

220-440V

-

Power:

-

15kw, 15kw

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

XTPACK BALER

-

Weight:

-

7 KG

-

Dimension(L*W*H):

-

3734*1098*3700mm

-

Product name:

-

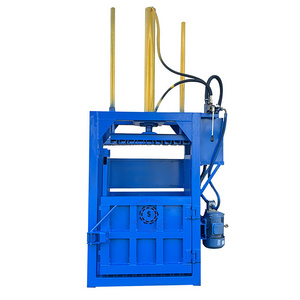

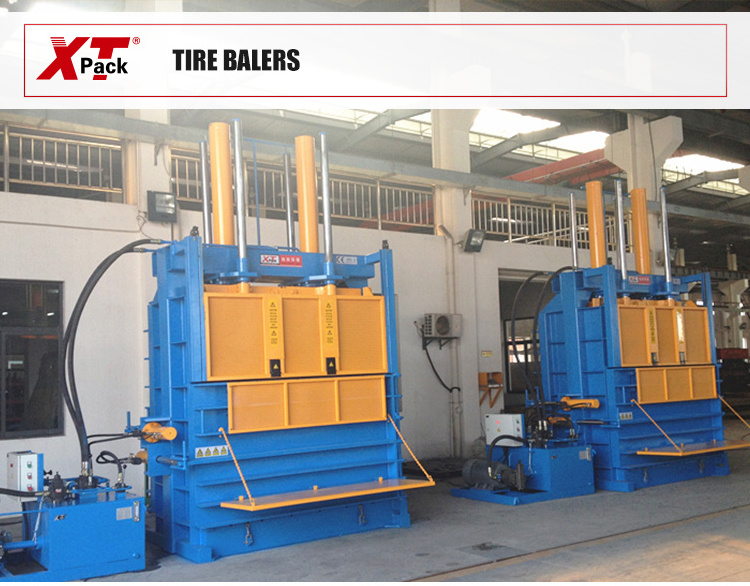

Tire balers

-

Baling Chamber Size:

-

1530*790*1800mm

-

Bale size(L*W*H)After expansion:

-

1600*850*1200mm

-

Bale weight:

-

1tons

-

Usage:

-

Specially designed for compressing rubber products like tires etc

-

Bale size*(L*W*H,H is adjustable):

-

1530*790*(1500-1200)mm

-

After Warranty Service:

-

Online support,Engineers available to service machinery overseas

-

Local Service Location:

-

India,Japan

-

Certification:

-

CE ISO

Vertical hydraulic scrap tire baling baler machine for sale

| Model | XTY-1200LF15379 | XTY-1200LF210120 |

|

Pressure |

120tons | 120tons |

|

Power |

15kw | 22kw |

|

Baling Chamber Size(L*W*H) |

1530*790*1800mm | 2100*1200*2100mm |

|

Bale size (L*W*H,H is adjustable) |

1530*790*(500-1200)mm | 2100*1200*(700-1400)mm |

| Bale size(L*W*H)After expansion | 1600*850*1200mm | 2200*1300*1400mm |

|

Bale weight |

1tons |

1.9tons |

|

Machine weight |

7tons | 12tons |

|

Machine Size (L*W*H) |

3734*1098*3700mm | 4231*1510*4300mm |

Features

- Hydraulic-driven opening door ensures operational safety and easier opening & closing

-

Two split platens with movable links to protect the platen from being distorted when pressing uneven materials like rubber tire etc

-

Whole system manual control to make sure durability and simple operation

-

Retractable retainer claws prevent the compacted bales to rebound

-

Employ whole set Taiwan hydraulic system

-

Mainly use Schneider electric components

-

Employ Japanese A.M.C. oil pipe joint makes sure no oil leakage

-

Auto chain bale ejector for easy operation and greater efficiency ( the bale can be automatically ejected out by the lifting chains)

-

Front & Back opening doors for convenient strapping and bale ejecting

-

Equip with air cooler to keep oil under normal temperature so that make sure perfect machine working performance