- Product Details

- {{item.text}}

Quick Details

-

Rolling thinckness:

-

0.5-1.5mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Demma

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

8.8m*2.3m*2.35m

-

Weight:

-

11500 kg

-

Feeding width:

-

600mm, 600mm

-

Name:

-

Arch Span Forming Machine

-

Rollers materials:

-

Hard chrome coated 45# steel

-

Shaft material:

-

#45 steel

-

Cutting Material:

-

Cr12Mov Heat treatment

-

Total Power:

-

15kw

-

Effective width:

-

305mm

-

Thickness:

-

0.4 to 1.5mm

-

Suitable material:

-

Colored steel

-

Usage:

-

stee arch roof

Quick Details

-

Type:

-

Arching Machine

-

Tile Type:

-

Colored Steel

-

Production Capacity:

-

15 m/min

-

Rolling thinckness:

-

0.5-1.5mm

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

Demma

-

Voltage:

-

380V 50Hz 3phases

-

Dimension(L*W*H):

-

8.8m*2.3m*2.35m

-

Weight:

-

11500 kg

-

Feeding width:

-

600mm, 600mm

-

Name:

-

Arch Span Forming Machine

-

Rollers materials:

-

Hard chrome coated 45# steel

-

Shaft material:

-

#45 steel

-

Cutting Material:

-

Cr12Mov Heat treatment

-

Total Power:

-

15kw

-

Effective width:

-

305mm

-

Thickness:

-

0.4 to 1.5mm

-

Suitable material:

-

Colored steel

-

Usage:

-

stee arch roof

Description

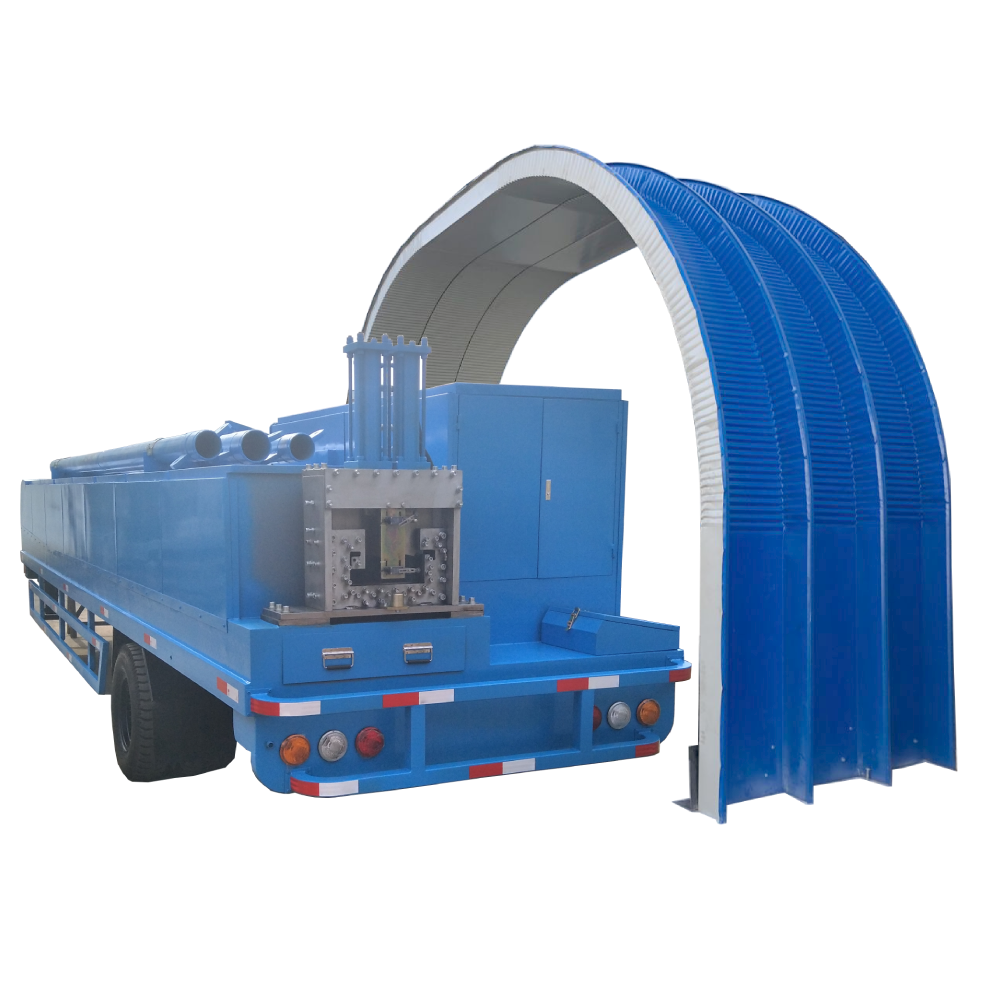

Arch Span Forming Machine

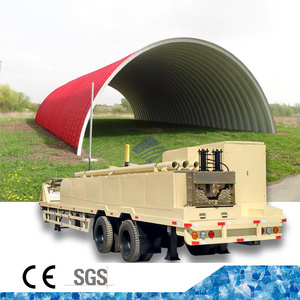

Our arch span forming machine is widely used for storages, hangars, warehouse, working shop, garages, medical facilites and agricaltural so on.

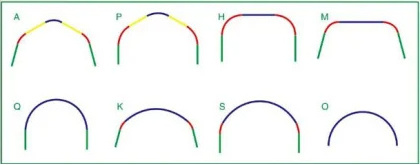

As there are various shapes of roofing panels, we provide you with a custom service.

-Producible Shapes of Building:

-Specifications of Arch Span Forming Machine:

|

Product name

|

Arch Span Forming Machine

|

|

Dimension

|

8.8 m*2.3m*2.35m

|

|

Total weight

|

about 11.5 tons

|

|

Voltage

|

380V/ 3 phase/ 50 Hz (or as your requirements)

|

|

Control system

|

Automatic PLC control system

|

|

Feeding thickness

|

0.4-1.5mm

|

|

Cutting method

|

Hydraulic cutting

|

|

Suitable material

|

Galvanized Steel Sheet, Colored Steel Sheet, Galvalume

|

-Details of Arch Span Forming Machine:

Famous Brand PLC SIEMENS (Automatic and Manual Changeable control system)

De-Coilers

It is easier to adjusting and faster to loading a steel coil

Hydraulic Cutting system

Hydraulic Cutting system (More stable & powerful)

PLC Automatic Control

Cutting Blade material: Real Cr12

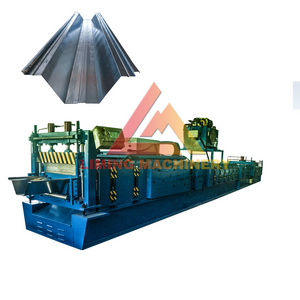

Roller

16 roller stations, more than 25 working steps

Rollers materials: Hard chrome coated 45# steel (reducing the roller wear)

The surface is polished

Shaft material

Real Solid Galvanized high grade #45 steel Much stronger than normal

Curving leaves materials

Cr40,The surface is polished (stop scratching the steel sheets)

30KW Diesel Generator

Be mounted on the machine

BUILDING TYPES

MORE CHOOSE

Shipping & Delivery

1. Packing type:wooden case,also be packaged according to customer requirements.

2. We will send photos and videos for your reference before shipment.

Hot Searches