- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

OEM

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YL

-

Product Name:

-

Marine Propeller Shaft

-

Material Processing:

-

Forging, Casting, Welding

-

Heat Treatment:

-

Quenching & Tempering, Surface Hardening

-

Machining Tolerance:

-

Max. 0.01mm

-

Machining Roughness:

-

Max. Ra 0.4

-

Defect Control:

-

UT, MT, PT, RT

-

Chemical Compositions:

-

spectrometer

-

Standard:

-

GB, EN, DIN, ASTM, GOST, JIS, ISO

-

Weight/Unit:

-

100kgs - 60 000kgs

-

Certification:

-

ISO 9001

Quick Details

-

Weight (KG):

-

3000

-

Material:

-

steel

-

Torque Capacity:

-

Customers' Request

-

Model Number:

-

OEM

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

YL

-

Product Name:

-

Marine Propeller Shaft

-

Material Processing:

-

Forging, Casting, Welding

-

Heat Treatment:

-

Quenching & Tempering, Surface Hardening

-

Machining Tolerance:

-

Max. 0.01mm

-

Machining Roughness:

-

Max. Ra 0.4

-

Defect Control:

-

UT, MT, PT, RT

-

Chemical Compositions:

-

spectrometer

-

Standard:

-

GB, EN, DIN, ASTM, GOST, JIS, ISO

-

Weight/Unit:

-

100kgs - 60 000kgs

-

Certification:

-

ISO 9001

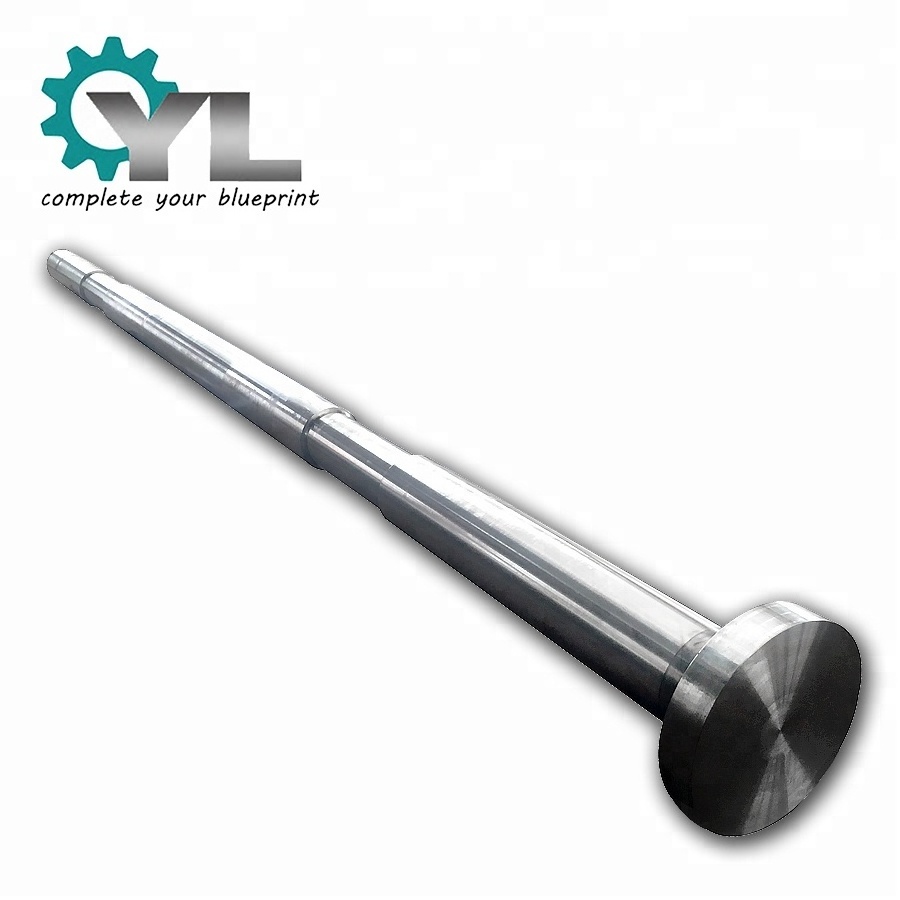

OEM Alloy Steel Forged Precision Spline Shaft Marine Propeller Shaft

Product Name: OEM Alloy Steel Forged Precision Spline Shaft Marine Propeller Shaft

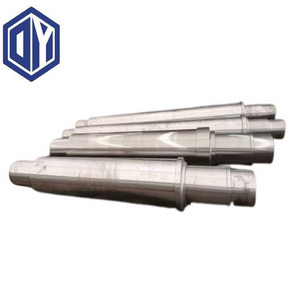

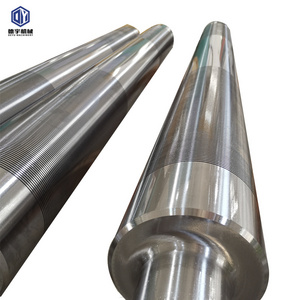

We are specialized in manufacturing different type of large mechanical products according to engineer drawings.

The products include gears, pinions, sprockets, shafts, wheels, rollers, couplings, pulleys, housings ,frames, molds, nonstandard machinery parts, wear resistant parts and structural components.

|

Material Standard

|

GB, EN, DIN, ASTM, GOST, JIS, ISO

|

|

|

|||

|

Material Processing

|

Forging, Casting, Welding

|

|

|

|||

|

Heat Treatment

|

Annealing, Normalizing, Q&T, Induction Hardening

|

|

|

|||

|

Machining Tolerance

|

Max. 0.01mm

|

|

|

|||

|

Machining Roughness

|

Max. Ra 0.4

|

|

|

|||

|

Module of Gear

|

8-60

|

|

|

|||

|

Accuracy of Teeth

|

Max. ISO Grade 5

|

|

|

|||

|

Weight/Unit

|

100kgs - 60 000kgs

|

|

|

|||

|

Application

|

Mining, Cement, Construction, Chemical, Oil Drilling, Steel Mill, Sugar Mill and Power Plant

|

|

|

|||

|

Certification

|

ISO 9001

|

|

|

|||

|

OEM AND ODM SERVICE ARE OFFERED

|

|

|

|

|||

1.Chemical Compositions Test

2.Mechanical Properties Test (Tensile Strength, Yield Strength, Elongation, Reduction of Area, Impact Value, Hardness)

3.Non Destructive Test (UT, MT, PT, RT)

4.Dimensional Checking

Customer Satisfaction

Good Quality of Products

On Time Delivery

are our pursue goal all the time.

Each of our product has been manufactured with the highest quality materials and followed the most appropriate procedures to make sure the long lifespans of use.

Technical Supports are fully provided for suggestion of new materials, designing drawings, measuring and mounting service.