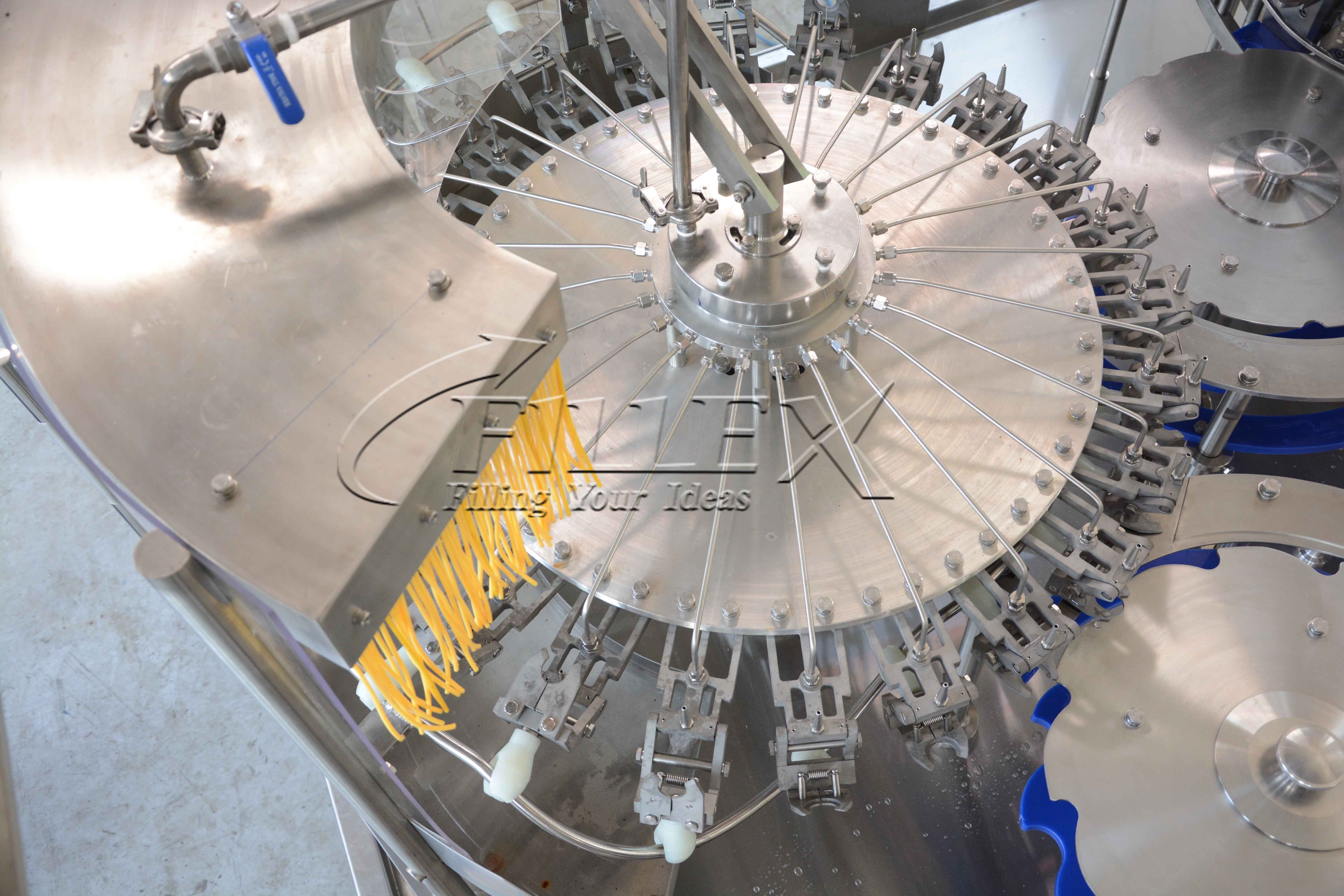

The carbonated drinking filling machine could be separated to 3 modules. The height of the bottle-out conveyor is adjustable.

Bottles are conveyed to rinser, filler and capper through starwheel and conveyed out finally through bottle-out conveyor. Equip with alarm device for bottle block, bottle absence, cap absence and overload. The machine meets the national food hygienic standard, with high automation and easy to operate.

- Product Details

- {{item.text}}

Quick Details

-

Filling Accuracy:

-

99%

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fillex

-

Weight:

-

2000 KG

-

Product name:

-

Bottle Filling Capping

-

Suitable for:

-

Carbonated Drink Filling Line

-

Function:

-

Washing Filling Capping

-

After-sales Service Provided:

-

1 Year

-

Bottle type:

-

PET Plastic Bottle

-

Production capacity:

-

3000-48000BPH

-

Material:

-

Stainless Steel 304/316

-

Advantage:

-

Automatic Working

-

Control:

-

PLC+ Touch Screen

-

Usage:

-

Easy Operation

Quick Details

-

Machinery Capacity:

-

4000BPH, 8000BPH, 12000BPH, 6000BPH, 20000BPH, 16000BPH

-

Packaging Material:

-

Plastic, Metal

-

Filling Material:

-

Other

-

Filling Accuracy:

-

99%

-

Voltage:

-

380V 50Hz

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Fillex

-

Weight:

-

2000 KG

-

Product name:

-

Bottle Filling Capping

-

Suitable for:

-

Carbonated Drink Filling Line

-

Function:

-

Washing Filling Capping

-

After-sales Service Provided:

-

1 Year

-

Bottle type:

-

PET Plastic Bottle

-

Production capacity:

-

3000-48000BPH

-

Material:

-

Stainless Steel 304/316

-

Advantage:

-

Automatic Working

-

Control:

-

PLC+ Touch Screen

-

Usage:

-

Easy Operation

Products Description

CARBONATED SOFT DRINK FILLING PACKING MACHINE

Product Paramenters

|

Model

|

RFC-C14-12-5

|

RFC-C16-16-5

|

RFC-C24-24-8

|

RFC-C32-32-10

|

RFC-C 40-40-10

|

RFC-C 50-50-12

|

|

Capacity

(500ML)

|

3000

|

5000

|

8000

|

10000

|

13000

|

16000

|

|

Rinser head

|

14

|

16

|

24

|

32

|

40

|

50

|

|

Filler head

|

12

|

16

|

24

|

32

|

40

|

50

|

|

Capper head

|

5

|

5

|

8

|

10

|

10

|

12

|

Details Images

Recommend Products

This machine works harmoniously with air-conveyor belt; it holds the bottles by the neck when transporting.This machine is used to fill still water into pet bottle and with screw caps capping function.Integrated three function: 1. Rinse the empty pet bottle, 2.filling the juice pulp 3. filling the rinsed bottles 4. capping sealing.

Water is the main content of the beverage, high quality water to make good drinks. Except the product itself, the beverage production line requires using the technical water, such as washing water and cooling water. No matter the bottled water, beverage product water and technical water, all are from treated raw water.

Blowing & Filling & Packaging Machine Manufacturer

Fillex Beverage Machinery

FILLEX was established in 2006, possessed with 10000 square meters standard workshop and more than 80 professional workers. FILLEX has adhered to our long-term concept of "Filling Your Ideas " & "Packing Your Ideas".During the 15 years since the establishment of our company, our products are sold to many other countries like the United States, Canada, Ghana, Peru, Argentina,Russia, South Africa, Vietnam, Philippines, Pakistan, Malaysia ,Saudi Arabia,Jordan and so on.

We provide solutions for blow molding, water treatment, beverage processing systems,blowing filling and packaging solutions. Mainly for liquids such as pure water, fruit drinks, carbonated beverages, beer, condiments, cosmetics and so on.

Fillex Exhibitions

FAQ

Q. Are you a trading company or manufacture?

A: We are manufacture ,we have our professional manufacturing teams and technicians.

Q: Do you have technical support?

A: Our company is responsible for installation and debugging of equipment, meanwhile, responsible for the technology and operation

training for user operator.

Q: How is your delivery time?

A: Generally speaking, the sample order takes 5-7 days, and it takes 15-25 working days for the bulk order after receiving the

payment. The exact delivery time depends on the project project and the number of orders.

Q: How do you make our business long-term and good relationship?

A1. We maintain good quality and competitive prices to ensure our customers benefit;

A2. We respect every customer as our friend, we sincerely do business with them and make friends with them, no matter where they come from. We are partners.

A: We are manufacture ,we have our professional manufacturing teams and technicians.

Q: Do you have technical support?

A: Our company is responsible for installation and debugging of equipment, meanwhile, responsible for the technology and operation

training for user operator.

Q: How is your delivery time?

A: Generally speaking, the sample order takes 5-7 days, and it takes 15-25 working days for the bulk order after receiving the

payment. The exact delivery time depends on the project project and the number of orders.

Q: How do you make our business long-term and good relationship?

A1. We maintain good quality and competitive prices to ensure our customers benefit;

A2. We respect every customer as our friend, we sincerely do business with them and make friends with them, no matter where they come from. We are partners.

Hot Searches