- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HAOMEI

-

Power:

-

110kw

-

Dimension(L*W*H):

-

33.8m*14.8m*10.8m

-

Weight:

-

4600 kg

-

Product name:

-

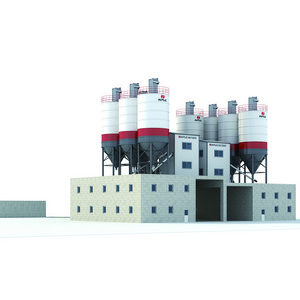

Cement concrete batching plant equipment with maintenance and services

-

Main Mixer::

-

JS1000

-

Power of Main Mixer::

-

37kw

-

Feeding Mode::

-

Lifting hopper

-

Mixing Time::

-

60s

-

Max Aggregate Size::

-

60/80mm

-

Discharging Height::

-

3.8m/4.1m(for customers choice)

-

Control Mode::

-

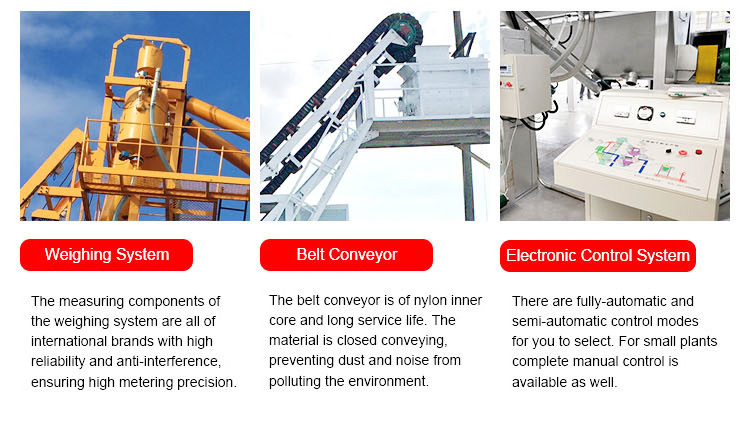

Automatic Control System/Central Console Control System

-

Cement Silo:

-

Required on clients' demand, 50T,100T available

-

Cement Screw:

-

Each cement silo equipped with one 219 screw

Quick Details

-

Machine Type:

-

Production line

-

Marketing Type:

-

New Product 2023

-

Core Components:

-

mixer

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

HAOMEI

-

Power:

-

110kw

-

Dimension(L*W*H):

-

33.8m*14.8m*10.8m

-

Weight:

-

4600 kg

-

Product name:

-

Cement concrete batching plant equipment with maintenance and services

-

Main Mixer::

-

JS1000

-

Power of Main Mixer::

-

37kw

-

Feeding Mode::

-

Lifting hopper

-

Mixing Time::

-

60s

-

Max Aggregate Size::

-

60/80mm

-

Discharging Height::

-

3.8m/4.1m(for customers choice)

-

Control Mode::

-

Automatic Control System/Central Console Control System

-

Cement Silo:

-

Required on clients' demand, 50T,100T available

-

Cement Screw:

-

Each cement silo equipped with one 219 screw

Cement concrete batching plant equipment with maintenance and services

Models and Technical Specifications 1 of Cement concrete batching plant equipment with maintenance and services

|

Type |

HZS25 |

HZS35 |

HZS50 |

HZS75 |

|

|

Theoretical production capacity(m3/h) |

25 |

35 |

50 |

75 |

|

|

Concrete mixer |

Type |

JS500 |

JS750 |

JS1000 |

JS1500 |

|

Power(KW) |

24.75 |

38.6 |

51 |

65.5 |

|

|

Discharging capacity(L) |

500 |

750 |

1000 |

1500 |

|

|

Aggregate size(mm) |

80/60 |

80/60 |

80/60 |

80/60 |

|

|

Aggregate Bin volume(m3) |

3.2 |

7.3 |

8.3 |

12 |

|

|

Weighing Accuracy |

Aggregate (KG) |

1500Kg ±2% |

2200Kg ±2% |

3000Kg ±2% |

4500Kg ±2% |

|

Cement(KG) |

300Kg ±1% |

450Kg ±1% |

600Kg ±1% |

1500Kg ±1% |

|

|

Fly ash(KG) |

|

|

400Kg ±1% |

600Kg ±1% |

|

|

Water (KG) |

200Kg ±1% |

200Kg ±1% |

400Kg ±1% |

600Kg ±1% |

|

|

Additive(KG) |

|

30Kg ±1% |

50Kg ±1% |

50Kg ±1% |

|

|

Total power(KW) |

45Kw |

60Kw |

115Kw |

110KW |

|

|

Discharging height(M) |

3.8 m |

3.8 m |

3.8 m |

3.8m |

|

|

Gross weight(T) |

7.7 |

15 |

40 |

50 |

|

Models and Technical Specifications 2 of Cement concrete batching plant equipment with maintenance and services

|

Type |

HZS60 |

HZS90 |

HZS120 |

HZS180 |

HZS240 |

||

|

Theoretical production(m3/h) |

60 |

90 |

120 |

180 |

240 |

||

|

Concrete mixer |

Type |

JS1000 |

JS1500 |

MAO3000/2000 |

MAO4500/3000 |

MAO6000/4000 |

|

|

Power(KW) |

18.5 |

65.5 |

74 |

110 |

150 |

||

|

Discharging capacity(L) |

1000 |

1500 |

2000 |

3000 |

4000 |

||

|

Aggregate size(Pebble/Macadam)(mm) |

80/60 |

80/60 |

80 |

150 |

150 |

||

|

Aggregate Bin volume(m3) |

8.38 |

12 |

20 |

30 |

40 |

||

|

Belt conveying Capacity(t/h) |

300 |

450 |

550 |

650 |

900 |

||

|

Weighing Accuracy |

Aggregate (KG) |

3000Kg ±2% |

3000Kg ±2% |

2200Kg ±2% |

3000Kg ±2% |

4200Kg ±2% |

|

|

Cement(KG) |

1500Kg ±1% |

1500Kg ±1% |

1200Kg ±1% |

1800Kg ±1% |

2200Kg ±1% |

||

|

Fly ash(KG) |

600Kg ±1% |

900Kg ±1% |

400Kg ±1% |

500Kg ±1% |

800Kg ±1% |

||

|

Water (KG) |

600Kg ±1% |

600Kg ±1% |

500Kg ±1% |

800Kg ±1% |

1000Kg ±1% |

||

|

Additive(KG) |

50Kg ±1% |

50Kg ±1% |

50Kg ±1% |

80Kg ±1% |

80Kg ±1% |

||

|

Total power(KW) |

|

120Kw |

165Kw |

130Kw |

170KW |

220KW |

|

|

Discharging height(M) |

|

3.8 m |

4.1 m |

4.1m |

4.1m |

4.1m |

|

With excellent mixing effects and large capacity, the Cement concrete batching plant equipment with maintenance and services is the best choice for concrete manufacturers who have the high quality and consistency of the final concrete products. As an industry leader in Smart conneeco mix concrete batch plant for sale suppliers, the provision of coal-fired New ready mix concrete plant for hire in india is known for its durability, index effectiveness and ability.

Cement concrete batching plant equipment with maintenance and services usually adopts JS series of twin shaft batch mixer as the main mixer. Twin shaft concrete mixer is a compulsory concrete mixer, and has a stronger mixing effect than the self-falling concrete mixer higher mixing efficiency. It can be used to mix hard and dry concrete and lightweight aggregate concrete.

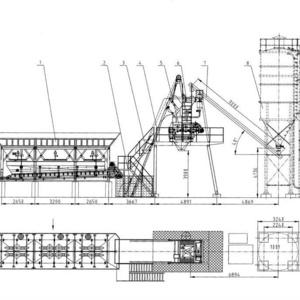

Aggregate batching system in the concreting batching plants, including the total supply system, weighing system and electrical control system. The feed device is driven by a belt. The batching system is controlled by the sensor.

Haomei machinery equipment co.,ltd is a famous manufacturer of quality stationary concrete batching plant, mobile concrete batching plant, concrete mixer, concrete trailer pump, concrete boom pump truck and concrete mixer truck etc. We adhere to the policy of "QUALITY FIRST AND INTEGRITY WINS" to cooperate with clients from all over the world. Seeking for long-term relationship and mutual benefit is our unstoppable goal.

Our company covers over 100 acres with workshop area of more than 50,000 square meters has 5 branches. We have over 1000 technical workers and 80 engineers equipped with advanced producing and inspecting machines with strict management. We focus greatly on our products quality and with such quality our products have been receiving admiration by clients from over 30 provinces in China and royal clients from overseas..

Our main products: HZS25, HZS35, HZS50, HZS60, HZS75, HZS90, HZS120, HZS 80 stationary concrete batching plant, YHZS25, YHZS35, YHZS60, YHZS75 mobile concrete batching plant, JS500, JS750, JS1000, JS1500, JS2000, JS3000, JS4000, SICOMA mobile concrete mixers, HBT series concrete trailer pump, concrete boom pump truck and concrete mixer truck with different capacities.

Q1: Which countries have you exported to?

Many countries like Indonesia, the Philippines, South Africa, Australia, Malaysia, Thailand, Singapore, Saudi Arab, Iraq, Pakistan, Nigeria, Algeria, Vietnam, Laos, Mongolia, Kenya, Ethiopia, Egypt, Garner, Tanzania, Zambia etc.

Q2: Is the Belt conveyor necessary ?

Small capacity (Below 60m3/h) normally use Skip Hopper to feed aggregate, no need to use belt conveyor.

While for large capacity, (Larger than 60m3h), normally use Delivery belt to raise efficiency.

Q3: What’s the lifetime of your machinery?

Usually 10 years under good maintenance.

Q4: What are components of a concrete batching plant?

An integrated plant should include the mixing plant, concrete delivery vehicles, experiment room devices, forklifts, floor scales, pump trucks, transformers, etc.

Q5: What’s the discharging height of a concrete mixing plant?

There are two types: 3.8m and 4.1m, and you can choose based on your requirements.

Q6: How long does it take to install the concrete batching plant?

Generally, it takes 2 weeks to install the whole set,and we will give you all necessary help.

Q7: How much is a set of ready mix concrete plant?

Please send inquiries directly to us. We will give a specific price based on your practical needs.