- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Higee

-

Weight:

-

Custom

-

Dimension(L*W*H):

-

Custom

-

Function:

-

fully automatic corrugated box making machine

-

Origin:

-

Shanghai

-

Certificat:

-

CE

-

Flute type:

-

U/A/B/C/D/E

-

A flute height:

-

4.7MM

-

B flute height:

-

2.7MM

-

E flute height:

-

1.7MM

-

Certification:

-

ISO

Quick Details

-

Voltage:

-

380V 50HZ

-

Power:

-

Custom, 380V,50HZ 3 phrase

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

Higee

-

Weight:

-

Custom

-

Dimension(L*W*H):

-

Custom

-

Function:

-

fully automatic corrugated box making machine

-

Origin:

-

Shanghai

-

Certificat:

-

CE

-

Flute type:

-

U/A/B/C/D/E

-

A flute height:

-

4.7MM

-

B flute height:

-

2.7MM

-

E flute height:

-

1.7MM

-

Certification:

-

ISO

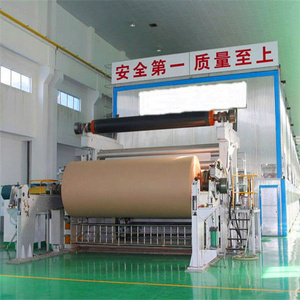

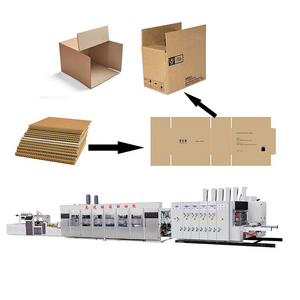

fully automatic corrugated box making machine

Descriptions:

Our company has developed ZYM series of roller printing and die-cutting machines,

which is a new ideal production equipment in carton production industry in recent years.

The device is mainly the automatic document feeder board,printing,slotting,corner cutting,trimming,drilling (any shape),

and other procedures forming a printing and die cutting equipment, the compact mechanical structure, simple operation,

adjustment convenient, advanced performance, high efficiency, ensure that processing of high-grade cardboard carton production industry an ideal replacement machine.

Suitable for a variety of shaped cardboard boxes or cartons.

Automatic Paper feeding part:

1. Cardboard size adjustment adopts screw roller adjusting system, one man operating, simple and fast.

2. Available for adjustable paper platform, more adaptable for kinds of cardboard, stable and precise paper feeding.

3. Adopts advanced seamless rubber strap, which has big friction, long life, low voice, easy maintenance and high economic efficiency.

4. Double stretch power control, convenient and reliable.

5. Transmission roll adopts decorative design roll, which increase the friction between strap and roll, ensure stable and fast cardboard feeding.

6. This machine includes electric and magnetic clutch separating brake system.

7. This machine adopts PLC auto program control, so it has high automatic extent.

8. Frequency converter drives motor to realize stable velocity change operating.

9. Light and electric signal brakes by PLC control power and magnetic clutch to keep pace with the main engine.

– Automation chain paper feed

– The prop fixes position, ensures that paper feed is accurate.

– Automatic counting.

n Printing Part

– Planetary transmission and electrical positioning. 360-degree adjustment in both dynamic and static condition.

– The embossing rollers get apart from printing template once machine stops.

– The upper ink roller is equipped with load-free system that prevents ink from getting dried when machine is running.

– Colors of 1 to 4 can be combined easily.

– The pneumatic provides ink circulatory system from attracting style.

– Top-quality paper separating and grooving blades are used.

– Printing roller equipped with a rapid hang mould device.

– Step pedal is used to control the side of printing plate when in mounting and dismounting.

Die Cutting Part:

Phase adjustment

1), the planetary gear structure.

2), the figures show that the phase-type instructions, to make operation more convenient, intuitive and accurate.

3), cutting the use of electric digital phase adjustment of 360 degrees (run, stop can be adjusted.) Modulation accuracy of 0.10 mm.

2. Cushion roll repair agency

Electric grinding bodies can be repeated 2-3 times.

3. Differential regulatory agencies

1). To ensure the cutting quality, the cushion roll gear adjusting mechanism installed outside the die roll and pads to ensure the roll speed are equal.

2). Mechanical rotating rollers move around 30 mm and with a radial differential system that allows the average distribution of roller wear

can greatly improve the life of the cot.

4. Balancing adjustment for increased stability.

T echnical Specifications :

|

Model |

Z Y M1200*2400 |

Z Y M1200*2800 |

|

Printing Colors |

Three Color |

Three Color |

|

Maximum Mechanical Velocity(pages/min) |

60 pages/min |

60 pages/min |

|

Maximum Size of Paper (MM) |

1 2 00* 22 00 |

1 2 00* 25 00 |

|

Maximum Size of Printing (MM) |

1 20 0*2 0 00 |

1 20 0*2 5 00 |

|

Minimum Size of Paper (MM) |

320*350 |

320*350 |

|

Maximum Size of Die-cutting(MM) |

1200*2000 |

1200*2500 |

|

Blade for Die-cutting (MM) |

25.4 |

25.4 |

|

Thickness of standard printing board (MM) |

7 |

7 |

|

Power of motor |

11KW |

15KW |

|

Precision for paper feeding |

D egree of bending of national standard, kicking paper error of plus or minus 1.5mm |

D egree of bending of national standard, kicking paper error of plus or minus 1.5mm |

|

Precision for die-cutting |

D egree of bending of national standard, slotting error of plus or minus 2.0mm |

D egree of bending of national standard, slotting error of plus or minus 2.0mm |

|

Precision of color register |

D egree of bending of national standard, color register error of plus or minus 1.5mm |

D egree of bending of national standard, color register error of plus or minus 1.5mm |

|

Size of machine |

7400 mm *38 00mm*2 5 00mm |

7400 mm *42 00mm*2 5 00mm |

2.Automatic Rotary Die Cutting Machine

Note; above models do width size according to customer to do a narrow width. The widest can be 3500mm.