- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

TYM

-

Dimension(L*W*H):

-

1550*1964*1380mm

-

Weight:

-

7000 KG

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

jaw crusher

-

Model Number:

-

PEX-250*1000

-

Size of Feeder Opening:

-

250*1000mm

-

Max.feeding size:

-

210mm

-

Size of output:

-

25-60mm

-

Capacity:

-

15-1000tph

-

motor power:

-

30-37kw

-

overall dimension:

-

1550*1964*1380mm

-

weight:

-

7000kg

-

Color:

-

Customer Requirement

Quick Details

-

Application:

-

building material

-

Capacity(t/h):

-

15-50

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

TYM

-

Dimension(L*W*H):

-

1550*1964*1380mm

-

Weight:

-

7000 KG

-

Marketing Type:

-

Hot Product 2022

-

Product name:

-

jaw crusher

-

Model Number:

-

PEX-250*1000

-

Size of Feeder Opening:

-

250*1000mm

-

Max.feeding size:

-

210mm

-

Size of output:

-

25-60mm

-

Capacity:

-

15-1000tph

-

motor power:

-

30-37kw

-

overall dimension:

-

1550*1964*1380mm

-

weight:

-

7000kg

-

Color:

-

Customer Requirement

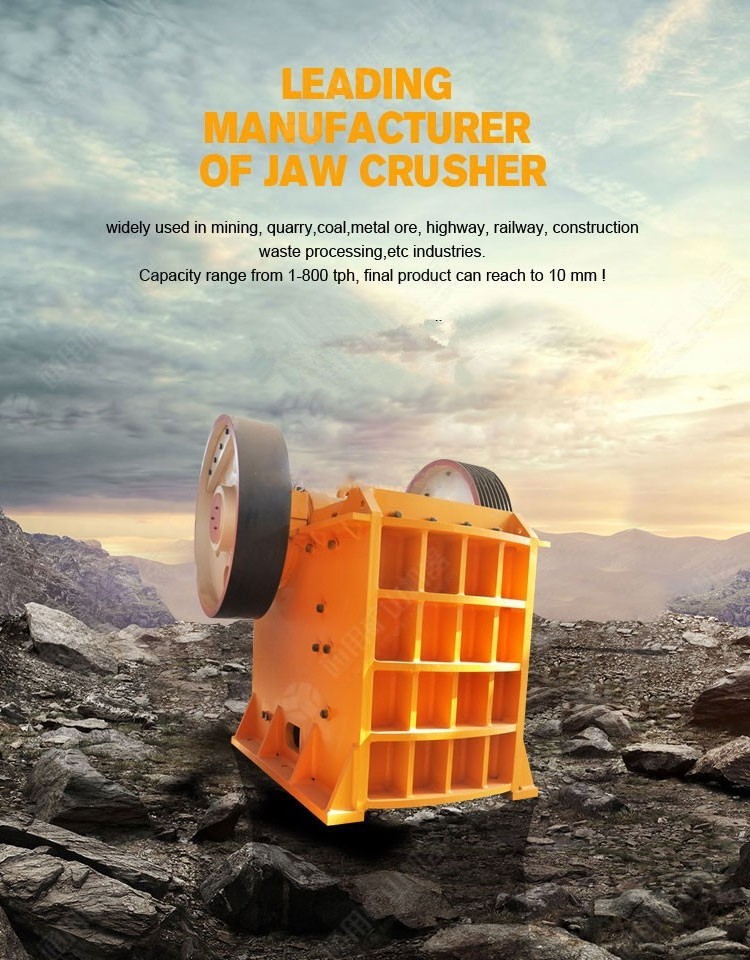

J aw crusher is mainly used to crush kinds of mining stones primarily,and the largest compression resistance of the material to be crushed is 320MPa.easy maintenance and less operating cost. And the jaw crusher is widely used in mining, metallurgical industry, building material, highway, rallway, and chemical industry.

working principle

The motor transmits power through belt,drives the moving jaw do periodic motion to the fixed jaw surround the eccentric shaft.The angle between toggle plate and moving jaw increases when moving jaw moves up.So the moving jaw closes to the fixed jaw.The stuff will be crushed in this process.The angle of Jaw Crushed between toggle plate and moving jaw descreases when moving jaw moves down, the moving jaw of Jaw Crusher moves away from fixed jaw by the pulling of rod and spring, the products after crushed will be discharged from the outlet of Jaw Crusher.

Jaw Crusher Technical Parameter

| Model | Size of Feeder Opening(mm) | Maximum Feeding Size(mm) | Adjustment range(mm) | capacity(t/h) | Motor Power(kw) | Overall Dimension(mm) | Weight(t) |

| PE150x250 | 150x250 | 125 | 10-40 | 1-3 | 5.5 | 896x745x935 | 0.8 |

| PE200x350 | 200x350 | 180 | 15-50 | 1-6 | 11 | 996x800x760 | 1.2 |

| PE250x400 | 250x400 | 200 | 20-50 | 5-20 | 15 | 1430x1310x1340 | 3 |

| PE400x600 | 400x600 | 350 | 40-100 | 15-60 | 30-37 | 1700x1732x1653 | 7 |

| PE500x750 | 500x750 | 425 | 50-100 | 40-110 | 45-55 | 2035x1921x2000 | 12 |

| PE600x900 | 600x900 | 480 | 65-160 | 90-180 | 55-75 | 2290x2206x2370 | 17 |

| PE750x1060 | 750x1060 | 630 | 80-140 | 110-320 | 90-110 | 2655x2302x3110 | 29 |

| PE900x1200 | 900x1200 | 750 | 95-165 | 220-450 | 110-132 | 3800x3166x3045 | 58 |

| PE1000x1200 | 1000x1200 | 850 | 200-220 | 280-560 | 132-160 | 5355x4280x3050 | 69 |

| PE1200x1500 | 1200x1500 | 1020 | 150-300 | 400-800 | 160-220 | 6380x5310x3710 | 100.9 |

| PEX150x250 | 150x250 | 125 | 10-40 | 1-3 | 5.5 | 800x700x800 | 1.5 |

| PEX150x750 | 150x250 | 125 | 18-50 | 5-16 | 15 | 896x745x935 | 3.8 |

| PEX250x750 | 250x750 | 210 | 25-60 | 15-30 | 22-30 | 1667x1545x1020 | 5 |

| PEX250x1000 | 250x1000 | 210 | 25-60 | 15-50 | 30-37 | 1550x1964x1380 | 7 |

| PEX250x1200 | 250x1200 | 210 | 25-60 | 20-60 | 37-45 | 2192x1900x1950 | 8.5 |

| PEX300x1300 | 300x1300 | 250 | 20-90 | 16-105 | 55 | 2720x1950x1600 | 15.6 |

The Advantage of Our Jaw Crusher

The Advantage of Our Jaw Crusher

1) Firm structure, stable performance, large capacity, even producing granularity.

2) With the increase of production, our jaw crusher can greatly reduce the operating costs.

3) Convenient maintenance and economical running expense..

4) The large feed opening and force-feeding action from the inward and downward eccentric movement of the swing jaw mean that our jaw crusher can increase the capacity.

5) It is widely used in mining, metallurgical industry ,building material ,highway, railway, water conservancy and chemical industries.

6) Various materials with compressive resistance less than 320Mpa can be crushed.

Application in production line

Application field

It is mainly used in the field of metallurgy, building materials, chemicals, mining and such mineral materials for grinding process. This mill can grind materials with Mohs hardness below 9.3 and humidity below 6%, variousnontlammable mineral materials„, such as quartz, feldspar, calcite, talcum, barite, fluorite, rare earth, marble,ceramics, bauxite, manganese ore, iron ore, copperore, phosphate rock, iron oxide red, Zircon sand, slagand so on.

Packing

1).Our crusher machines are packed in plastic bags.

2).The spare parts are packed in wooden cases.

3).Containers are our transport package.

4).Customization can be accepted.

Delievery

We are based on the actual needs of customers,to carry out talloe-made sales.By senior engineer to design scheme,after receipt of customer deposits began production,regardless of the equipment we can deliver the goods in two weeks,delivered the balance after delivery