- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

KAYO-RF530

-

Product Name:

-

Reflow Oven

-

Usage:

-

Circuit Board Soldering

-

Heating Zones:

-

5 Zones

-

Heating Length:

-

960mm

-

Max. PCB Width:

-

300mm

-

Power Supply:

-

AC220V /AC380V±10% 50Hz

-

Staring Power:

-

11KW

-

Working Power:

-

3.5KW

-

Dimensions:

-

L1700*W710*H650mm

-

Certification:

-

CE/ISO

Quick Details

-

Weight (KG):

-

150

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

KAYO

-

Model Number:

-

KAYO-RF530

-

Product Name:

-

Reflow Oven

-

Usage:

-

Circuit Board Soldering

-

Heating Zones:

-

5 Zones

-

Heating Length:

-

960mm

-

Max. PCB Width:

-

300mm

-

Power Supply:

-

AC220V /AC380V±10% 50Hz

-

Staring Power:

-

11KW

-

Working Power:

-

3.5KW

-

Dimensions:

-

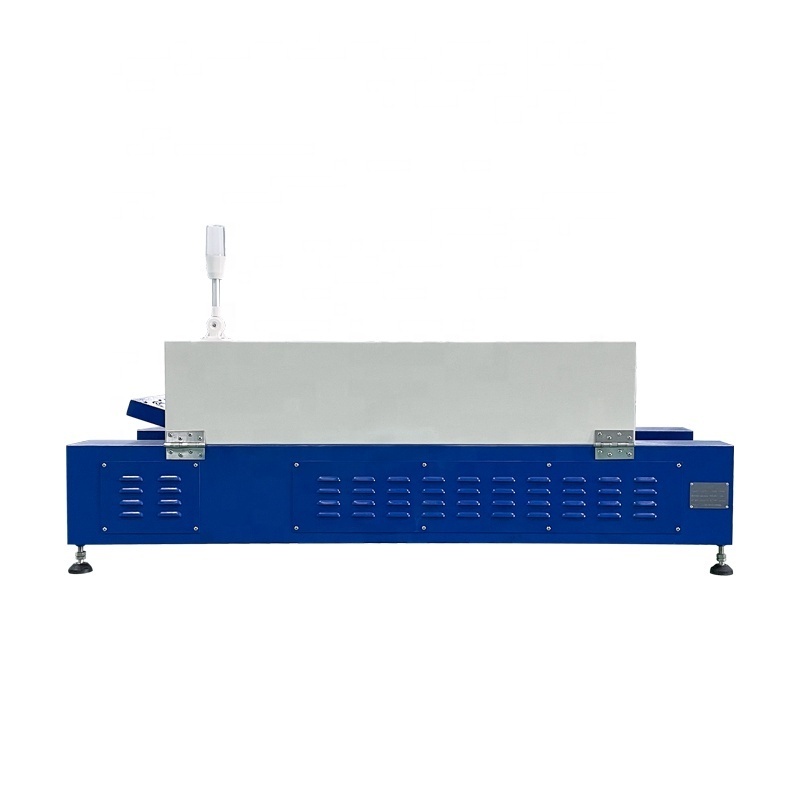

L1700*W710*H650mm

-

Certification:

-

CE/ISO

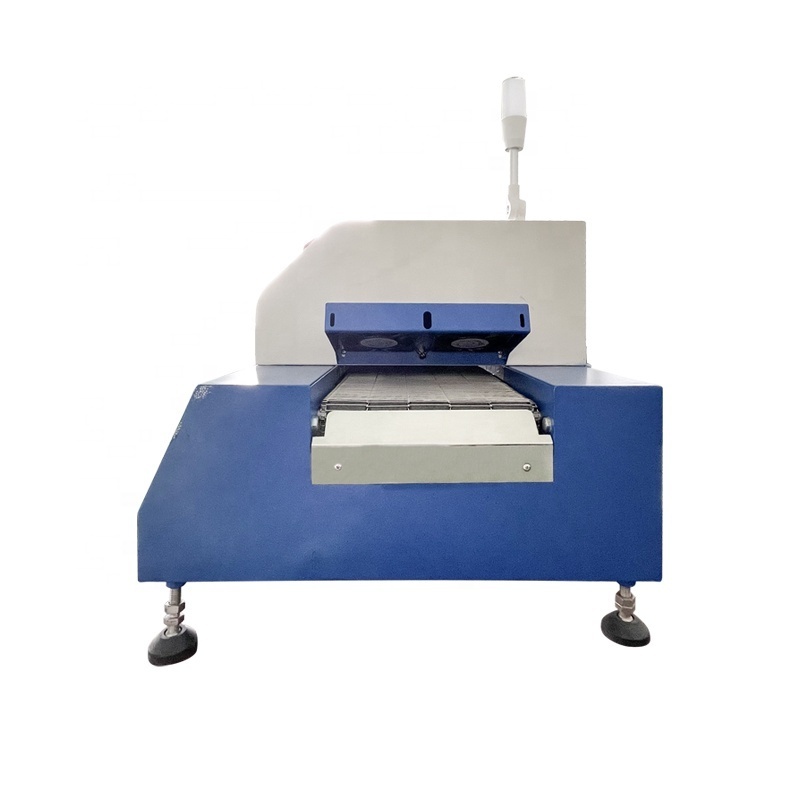

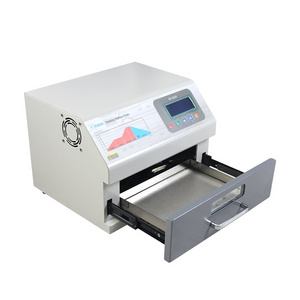

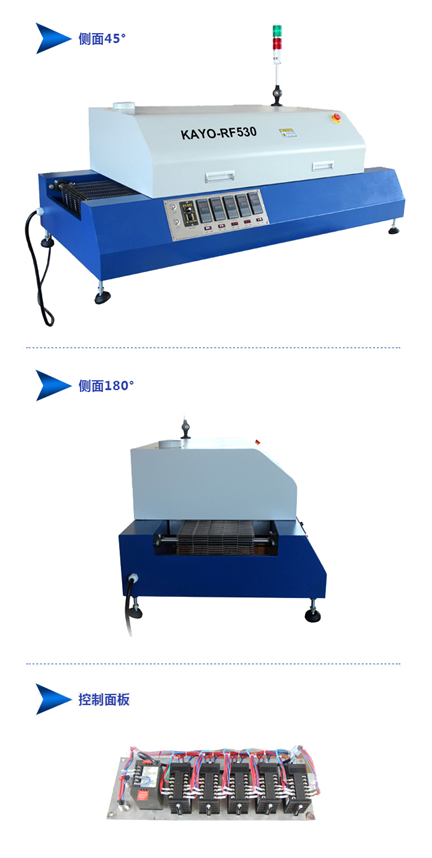

KAYO-RF530

Desktop 5 Heating Zones Reflow Oven

Product Display :

Product Details:

1. PID overall temperature control, easy to operate

1) External heating zones instrument and transport adjustment, which is more convenient for the customers to detect the temperature change and speed adjusting status, make sure the quality of the soldering.

2) Newest PID micro-computer overall temperature control system, which provides precise temperature control, quick heating-up, low energy consumption and high efficiency.

2. Ultra high temperature resistant motor

Adopt u ltra high temperature resistant motor, fast heat dissipation, high safety, greatly reducing the failure caused by excessive temperature.

3. High quality fan

Adopt high quality fan, fast heat dissipation, low fault, ensuring safe heat dissipation.

4. High temperature resistant & corrosion resistant finish

Oven adopt 800 degree High temperature resistant & corrosion resistant finish.

5. Precisely layout distribution box

The distribution box is precisely layout in the rear side of the machine for easy maintenance. It is extremely safe in both materials and design. Equipped with air switch, fuse, over temperature protection.

6. Thickening aluminum plate

Thickening aluminum plate could be more evenly distributed heat, better heat dissipation, more durable.

Product Specification:

|

Model |

KAYO-RF 5 30 |

|

Heating Zone |

Upper 3 Zones/ Down 2 Zone |

|

Heating Length |

960 mm |

|

Heating Method |

Hot Air Heating |

|

Control Mode |

Operation Panel Button + Intelligent micro computer meter PID Close Loop Control |

|

Warm-up time |

20min |

|

Time of Passing through the machine |

3.5~5.5 min |

|

Cooling Zone Quantity |

2 Air Cooling Zones |

|

Cooling Method |

Transverse Flow Forced Air Cooling |

|

Conveyor Width |

300mm |

|

PCB Max. Size |

280*280mm |

|

Component Permitted Height |

30mm |

|

Conveyor Direction |

Left→right (right→left optional) |

|

Transmission Net Height |

300±20mm |

|

Transmission Method |

Stainless steel mesh belt |

|

Conveyor Speed |

0-1 35 0mm/min |

|

Abnormal Alarm |

Extra-high / extra- low temperature alarm |

|

Power Supply |

AC220V /AC380V ± 10% 50Hz |

|

11 KW/ 3 .5KW |

|

|

Dimensions |

L1 7 00*W 7 10*H6 5 0mm |

|

Weight |

About 1 5 0KG |