- Product Details

- {{item.text}}

Quick Details

-

Design Style:

-

Modern

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SRT Hose

-

Model Number:

-

Shower Hose

-

Product name:

-

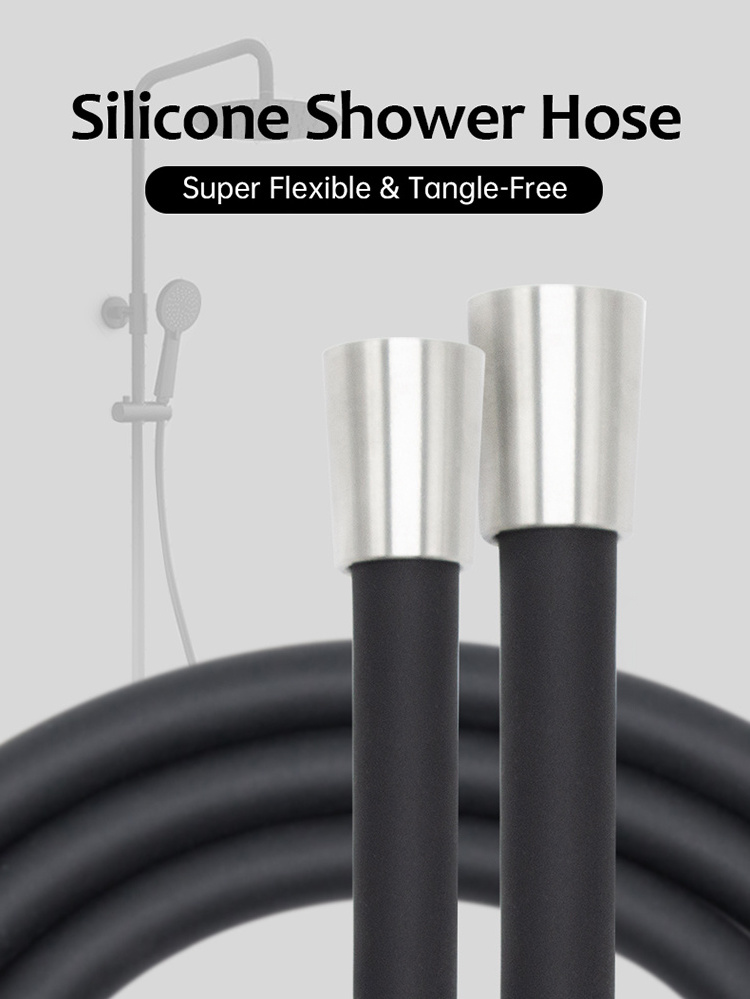

Flexible Silicone Shower Hose

-

Inner Tube:

-

PE Corrugated

-

Outer Hose:

-

Silicone

-

Interlayer:

-

Nylon Thread Braided

-

Nuts:

-

H57-3 Brass

-

Color:

-

Pink/Blue/Black/White/Light Brown/Gray

-

Work Pressure:

-

1.5Mpa

-

Burst Pressure:

-

3.5Mpa

-

Tension:

-

250N

-

Working Temperature:

-

-30 to 100 Degree C

Quick Details

-

Material:

-

PE Corrugated Inner Tube+Silicone Cover

-

Project Solution Capability:

-

graphic design, 3D model design, total solution for projects, Cross Categories Consolidation, Others

-

Application:

-

Bathroom,Barbershop

-

Design Style:

-

Modern

-

Place of Origin:

-

Zhejiang, China

-

Brand Name:

-

SRT Hose

-

Model Number:

-

Shower Hose

-

Product name:

-

Flexible Silicone Shower Hose

-

Inner Tube:

-

PE Corrugated

-

Outer Hose:

-

Silicone

-

Interlayer:

-

Nylon Thread Braided

-

Nuts:

-

H57-3 Brass

-

Color:

-

Pink/Blue/Black/White/Light Brown/Gray

-

Work Pressure:

-

1.5Mpa

-

Burst Pressure:

-

3.5Mpa

-

Tension:

-

250N

-

Working Temperature:

-

-30 to 100 Degree C

4 Lengths Available

3 Types of Connectors

Advantages of

Chrome-plated Copper Joints:

Chromium has excellent corrosion resistance and wear resistance, and can protect the surface of copper joints from oxidation and corrosion.

After chrome plating, the surface gloss is high and the texture is good, which can improve the aesthetics and grade of the product.The chrome plating process is mature, the surface of the copper joint after treatment is uniform and not easy to fade, and the service life is long.

Advantages of PVD:

The PVD process can form a hard and wear-resistant coating on the surface of the copper joint to improve the wear resistance and corrosion resistance of the copper joint.

PVD can prepare coatings of various colors and textures, which can meet the needs of different customers and enhance the design sense of the product.

The PVD-treated copper joint has a high surface finish and good gloss, which can improve the appearance and texture of the product.

Advantages of ORB:

The surface of the ORB-treated copper connector forms a layer of dark coating, which is not easy to leave fingerprints and water stains, and is easy to clean and maintain.

ORB has a natural, vintage texture and texture, which can enhance the texture and quality of the product.

ORB treatment is an environmentally friendly process that does not produce harmful gases and waste water, and is in line with the concept of sustainable development.

|

Features

|

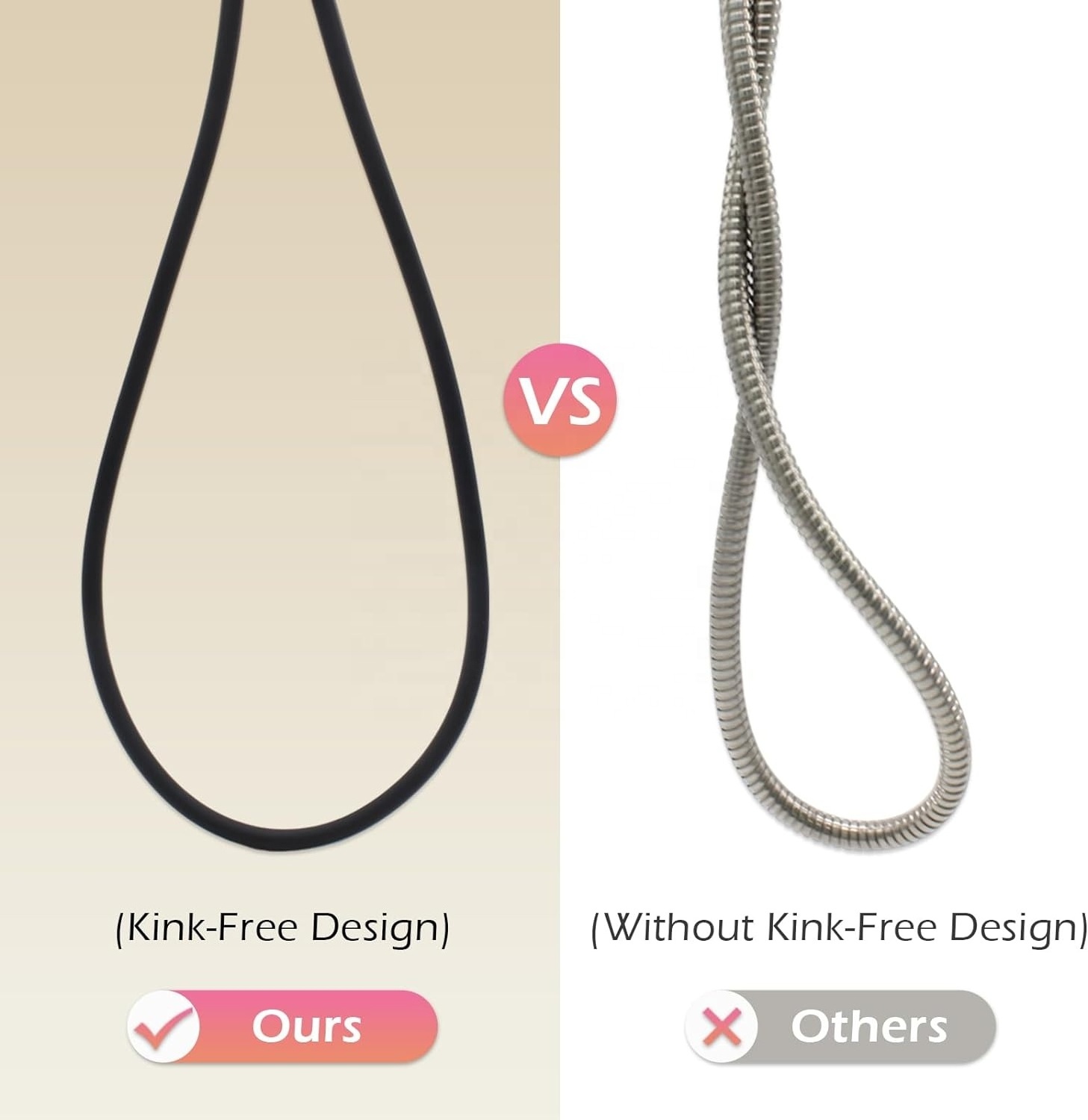

Auti-Twist Structure

Super Light, Flexible and Easy to Use G 1/2" Connection

|

|

Inner Hose

|

PE Corrugated (Non-Toxic)

|

|

Outer Hose

|

Silicone Rubber

|

|

Interlayer

|

Nylon Thread Braid

|

|

Nuts

|

H57-3 Brass

|

|

Work Pressure

|

≤1.5MPa

|

|

Burst Pressure

|

≤3.5MPa

|

|

Tension

|

≥500N

|

|

Temperature

|

Inner Hose≤ +100℃

|

|

Temperature

|

Outer Hose≤ +180℃

|

|

Warranty

|

Contact SRT for Detailed Warranty Information

|

JIANGSU SAINT-GERMAIN SHUNTONG TUBE INDUSTRY SCIENCE & TECHNOLO-GY CO., LTD.

(SRT TUBE) was founded in 2015, covering an area of more than 15,000 square meters, with a building area of 12,000 square meters.

Our company specializes in the production of sanitary-use braided drinking water safe flexible hose, patented semi-finished drinking water safe inner pipe, and new material research, development and sales.

SRT

possesses 5 faucet pull-out corrugated pipe production lines, 4 shower pipe production lines, 6 composite material certified inner pipe production lines, 2 PEX ice maker pipe production lines, and 2 refrigerator PEX special-shaped pipe production lines.

SRT

is cooperating with Hangzhou Wanma Group, Shandong Dawn Group and Zhengzhou University Experimental R&D Center, which makes us possessing leading technology. We have obtained 2 invention patents and 35 utility model patents.

SRT

maintains very good business relationship with Jomoo Sanitary Ware, Submarine Drain Ware, etc. which are super famous brands in domestic market. Our products are exported to foreign high-end markets such as Europe, North America, South Korea, Japan, Singapore, etc., ranking at the leading position in this industry.

SRT

committed to solving problems such as the instantaneous blasting pressure increase of the "water inlet pipe", taking full compliance with international direct drinking water safety standards as its own responsibility. With this constant pursuit, SRT is developing step-by-step and growing fast.

Hot Searches