- Product Details

- {{item.text}}

Quick Details

-

After sales service:

-

Engineers available

-

Environment:

-

Environment Fridendly

-

Color:

-

Customized

-

Application:

-

Automatic Spray Painting

-

Kinds of coating:

-

Liquid Coating

-

Keywords:

-

Painting Production Line

-

Control System:

-

PLC+Touch Screen Automatic

-

Name:

-

Painting Line

-

Install location:

-

Painting Spraying Equipment

-

Weight:

-

As per required

-

Certification:

-

SGS, ISO9001,CE

Quick Details

-

Place of Origin:

-

Guangdong, China

-

After-sales Service Provided:

-

Free spare parts, Field installation, commissioning and training, Field maintenance and repair service, Video technical support, Online support

-

Install:

-

Oversea service

-

After sales service:

-

Engineers available

-

Environment:

-

Environment Fridendly

-

Color:

-

Customized

-

Application:

-

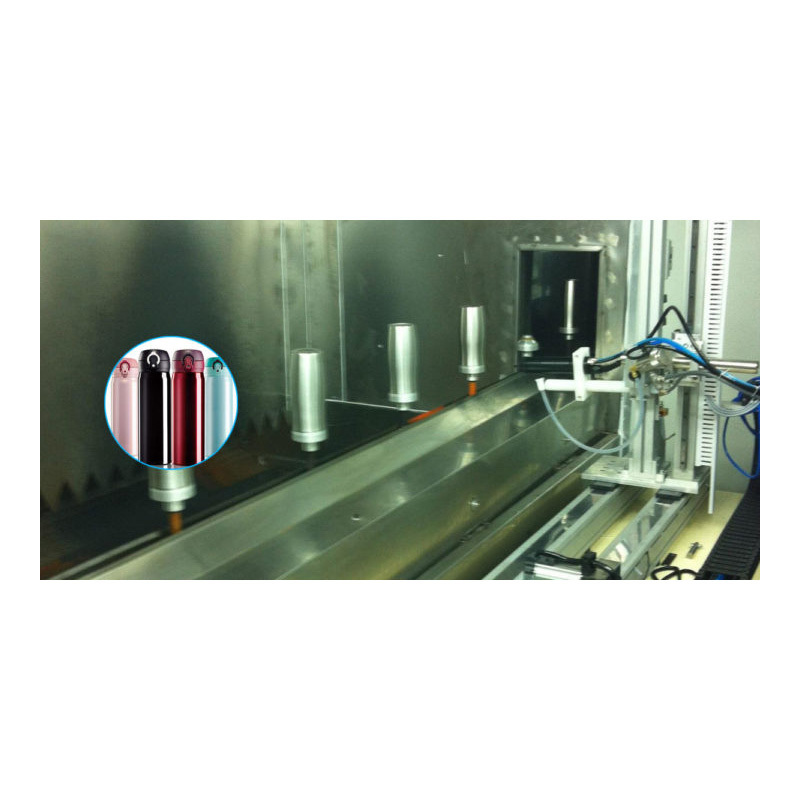

Automatic Spray Painting

-

Kinds of coating:

-

Liquid Coating

-

Keywords:

-

Painting Production Line

-

Control System:

-

PLC+Touch Screen Automatic

-

Name:

-

Painting Line

-

Install location:

-

Painting Spraying Equipment

-

Weight:

-

As per required

-

Certification:

-

SGS, ISO9001,CE

Welcome to Guanjie, and we are a factory producing Spray Painting Equipment, Powder Coating Equipment and Conveyors.

All equipment is customized as per your requirements.

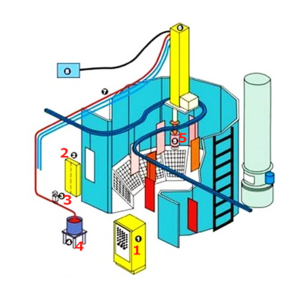

Main Systems Including

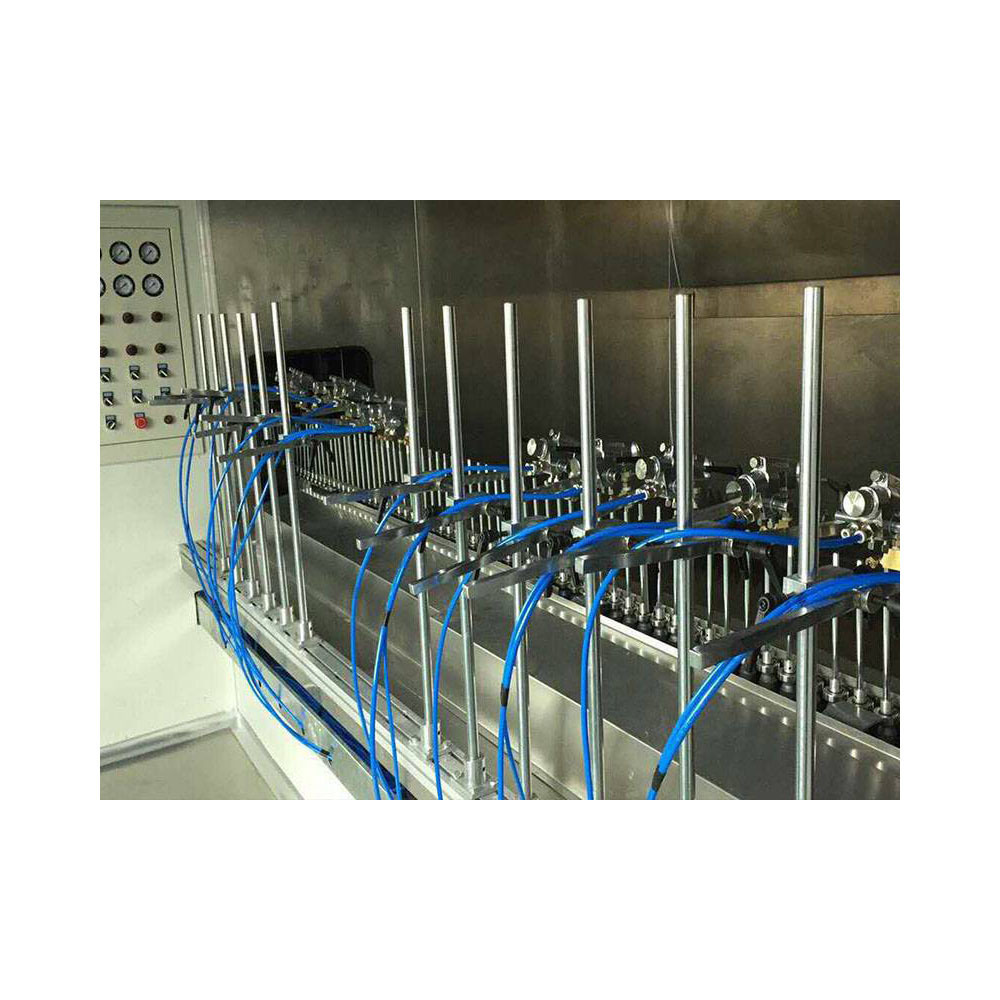

| Systems | Technical Process and Options |

| Pretreatment | Washing, degreasing, etching, phosphating, blasting |

| Spray Booths | Manual or automatic with powder recycle system |

| Drying&Curing Ovens | Tunnel ovens, bridge ovens |

| Heating Source | Coal/diesel/bio-particles/L.P.G./N.G./electricity |

| Transport system | Chain conveyor, power and free conveyor |

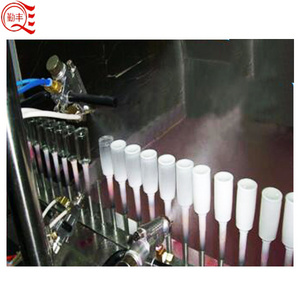

Spray Painting Production Line

Advantages:

1,Fexibility

(1) large scope of work, large possibility of audit.

(2) the inner surface and outer surface can be sprayed.

(3) it can realize the production of mixed lines of various models, such as the production of mixed lines of cars, station wagons, pickup trucks and so on.

2,Improve Spray Quality and Material Utilization Rate

(1) Profile spray track is accurate to improve the uniformity of coating film and other appearance spray quality.

(2) Reduce the amount of overspray and the amount of cleaning solvent, and improve the utilization rate of materials.

3,Easy to operate and maintain

(1) Off-line programming can greatly shorten the debugging time on site.

(2) Pluggable structure and modular design can achieve rapid installation and replacement of components, greatly reducing maintenance time.

(3) All parts have good accessibility for maintenance, which is convenient for maintenance.

4,High utilization rate of equipment.

(1) The utilization rate of reciprocating automatic spray machine is generally only 40%-60%, and the utilization rate of spray paint production line can reach 90%-95%.

Our company's automatic spray coating line requirements for the automotive exterior decoration: generally need three layers of painting (primer, color paint, topcoat), there are ways such as spraying for three times and baking for one time,or spraying for threes times and baking for two times, or even both of spraying and baking for three times.

Business Process: