- Product Details

- {{item.text}}

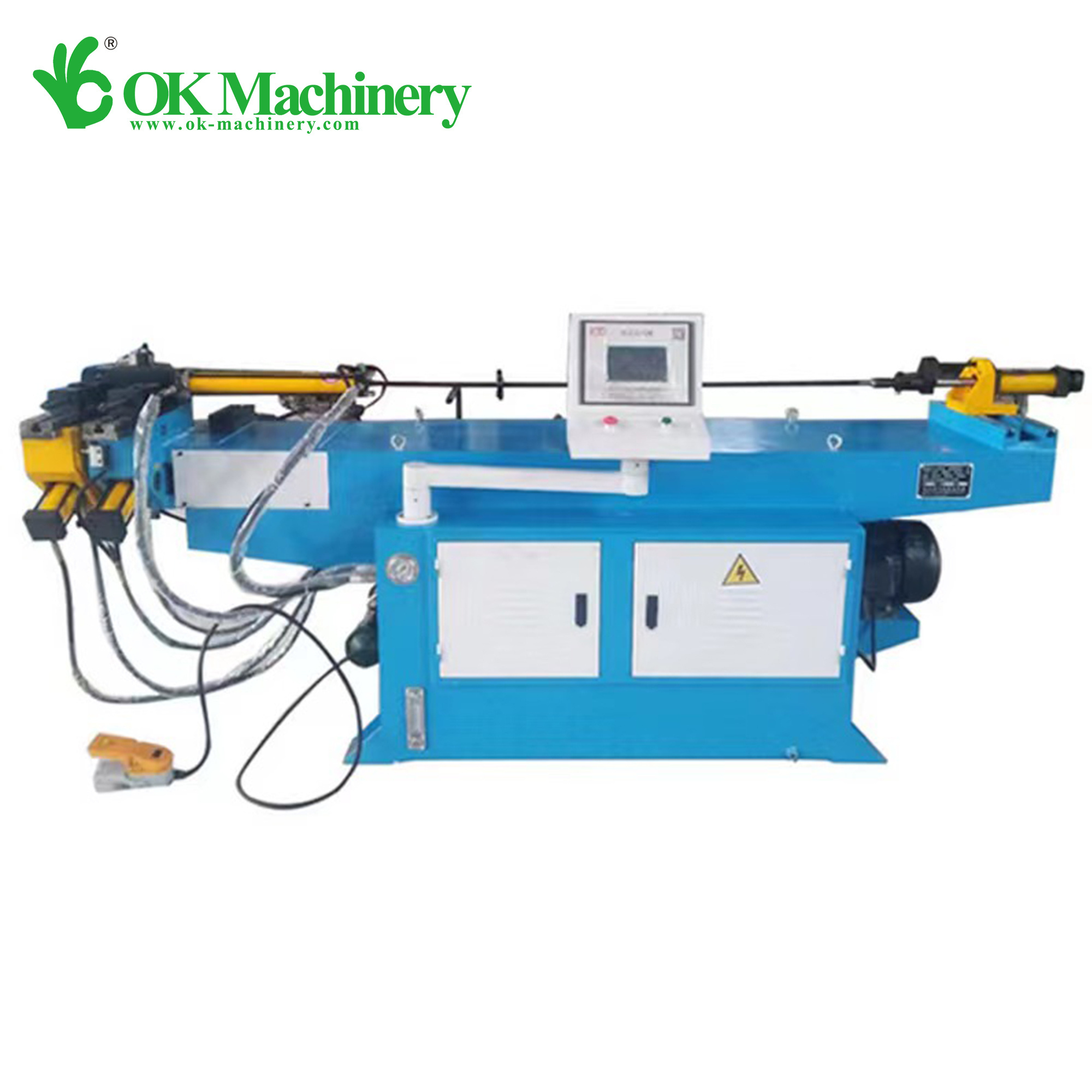

Quick Details

-

Bending Precision (Deg):

-

0.1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OK Machinery

-

Year:

-

2023

-

Power (kW):

-

5.5

-

Weight (KG):

-

800

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Tube Bending Machine

-

Application:

-

Tube Pipe Bending

-

Raw Material:

-

Round Pipe Square Tube

-

Keyword:

-

Tube Bender Electric

-

Material:

-

Stainess Steel

-

Function:

-

Steel Metal Bending

-

Control:

-

Touch Screen

-

Color:

-

Support Customized

-

Bending diameter range:

-

10-50mm Steel Pipe

-

After-sales Service Provided:

-

After-sales Service Provided

Quick Details

-

Machine Type:

-

Automatic

-

Bending Radius (mm):

-

1.5 - 350

-

Max. Bending Angle (Deg):

-

190

-

Bending Precision (Deg):

-

0.1

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

OK Machinery

-

Year:

-

2023

-

Power (kW):

-

5.5

-

Weight (KG):

-

800

-

Marketing Type:

-

New Product 2023

-

Product name:

-

Tube Bending Machine

-

Application:

-

Tube Pipe Bending

-

Raw Material:

-

Round Pipe Square Tube

-

Keyword:

-

Tube Bender Electric

-

Material:

-

Stainess Steel

-

Function:

-

Steel Metal Bending

-

Control:

-

Touch Screen

-

Color:

-

Support Customized

-

Bending diameter range:

-

10-50mm Steel Pipe

-

After-sales Service Provided:

-

After-sales Service Provided

Product Description

The folded sheet metal bending machine has

high productivity

and

high working accuracy

, using different shapes of up and down mould, can be bent into various shapes artifacts, slider stroke at a time can be to a bending forming of sheet metal, after a lot of bending can be achieved relatively complex shape workpiece, when equipped with the corresponding equipment, can also make a punch.

Specification

1). This machine adopts hydraulic electric control, sliding block stroke can be adjusted, and have some fixed, semi-automatic,automatic movements such as norm, using dynamic specification can easily test and adjustment

2). lift bending machine design,double oil cylinder work at the same time, balance, convenient operation, safety

3). The dead point have confirmed when rolling function, ensure that the workpiece precision

4). Under the condition of the relevant national standards, bending Angle precision of plus or minus 45 '.

5). A slow decline control function, the operator can better control the workpiece.

|

Name

|

Unit

|

Parameter

|

|

Max. Bending Capacity

|

mm

|

¢63*6

|

|

Bending Radius Range

|

mm

|

30-300

|

|

Max. Bending Angle

|

°

|

190°

|

|

Bending Speed

|

°/sec

|

30

|

|

Turning Speed

|

°/sec

|

160

|

|

Feeding Speed

|

mm/sec

|

800

|

|

Bending Precision

|

°

|

±0.10

|

|

Turning Precision

|

°

|

±0.10

|

|

Feeding Precision

|

mm

|

±0.10

|

|

Turning Servomotor Power

|

kW

|

1

|

|

Feeding Servomotor Power

|

kW

|

1.5

|

|

Though Effective Distance

|

mm

|

2600

|

|

System Motor Power

|

kW

|

7.5

|

|

Max. Pressure

|

Mpa

|

16

|

|

Oil Pump Delivery Volume

|

L

|

25

|

|

L*W*H (Packaging Dimension)

|

mm

|

5000*1200*1350

|

|

Weight

|

T

|

3.5

|

OK Machine Advantages

Pipe bending machine

is the product from the combination with our technology and advanced Italian technology, integrated with machine, hydraulic, and electricity. This series adopt VDU touch screen operating panel, which can input, store, and display various bending data and order. Y, B, C three coordinates of motions under precision control by industrial computer can realize full-auto mandrel on or mandrel off rapid bending.

The machine also with

advanced functions

, such as components bending spring back compensation, errors self diagnose alarm, memory store after power off, automatic lubrication and safety protection. Pipe bending(C axis), pipe rotating (B axis), and pipe feeding(Y axis) are all drove by closed ring servomotor. Advanced technology, high automation reliability, integrated design all make pipe bending machine the first class pipe processing machine in the world.

The steel plate welded structure

, with sufficient strength and stiffness, hydraulic transmission to ensure work is not due to the thickness of the sheet metal change or die "V" shaped groove choose undeserved and cause serious overload accident, in addition the machine working smoothly, with convenient operation, low noise, safe and reliable, etc

The oil cylinder is equipped with mechanical stop, ensure the repositioning precision of the slide block to the top dead center, to ensure the consistency of the bending Angle when mass production.

Customer Photos

Hot Searches