- Product Details

- {{item.text}}

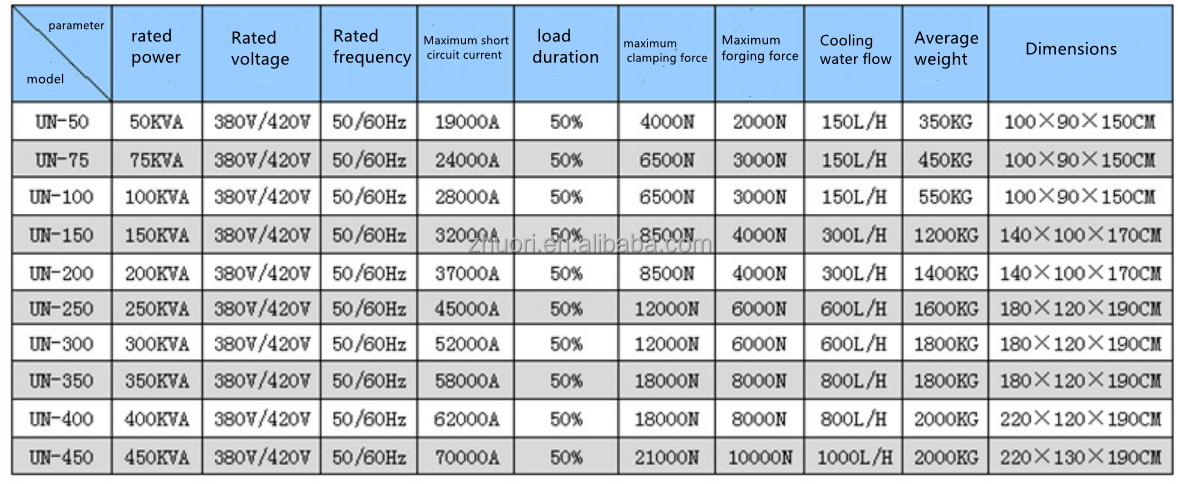

Quick Details

-

Current:

-

50HZ

-

Dimensions:

-

1000/1500/2000

-

Usage:

-

Stainless steel carbon steel

-

Power (kW):

-

1-10

-

Weight (KG):

-

360 KG

-

Application:

-

Wheel Rim Welding

-

Input voltage:

-

380V±10%

-

Color:

-

AS CUSTOMER NEED

-

Type:

-

AUTOMATIC

-

Payment:

-

100%

-

After-sales Service Provided:

-

1 YEAR

-

Service:

-

ALL LIFETIME

-

Welding Materials:

-

Carbon Steel Wire

-

Cooling Method:

-

COLD WATER AS DIFFERENT HOURS

-

Certification:

-

IECEE

Quick Details

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

ZHUORI

-

Input Voltage:

-

380V

-

Current:

-

50HZ

-

Dimensions:

-

1000/1500/2000

-

Usage:

-

Stainless steel carbon steel

-

Power (kW):

-

1-10

-

Weight (KG):

-

360 KG

-

Application:

-

Wheel Rim Welding

-

Input voltage:

-

380V±10%

-

Color:

-

AS CUSTOMER NEED

-

Type:

-

AUTOMATIC

-

Payment:

-

100%

-

After-sales Service Provided:

-

1 YEAR

-

Service:

-

ALL LIFETIME

-

Welding Materials:

-

Carbon Steel Wire

-

Cooling Method:

-

COLD WATER AS DIFFERENT HOURS

-

Certification:

-

IECEE

Product Description

|

product name

|

Butt welding machine, flash welding machine, foot welding machine, wire butt welding machine, steel butt welding machine, round

pipe and round steel butt welding machine,Butt welding machine for round tube and square tube with 45 degree angle,Butt welding machine for round tube and square tube with 90 degree angle,Round tube square tube T-shaped butt welding machine |

|

colour

|

customizable

|

Title goes here.

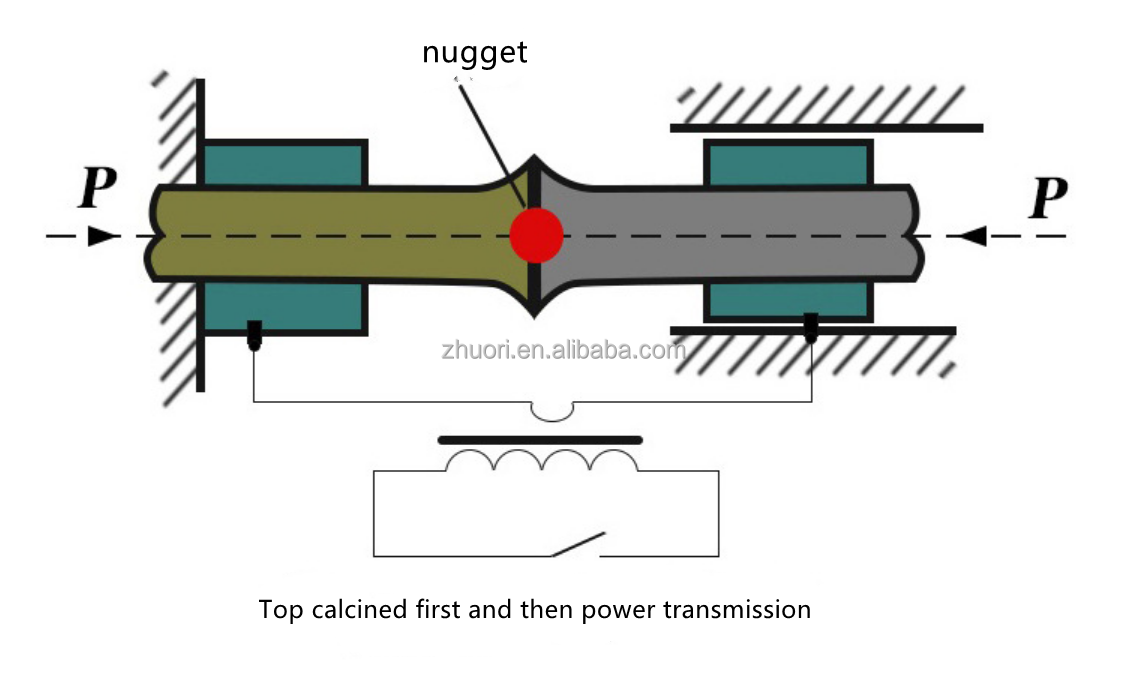

Butt welders are also known as current welders or resistance butt welders. Using the resistance between the contact surfaces of the two workpieces, a low voltage and a large current is instantaneously passed through, so that the contact surfaces of the two butt-jointed metals are instantly heated to melt and fuse.

Butt welding machine is divided into different welding methods: flash butt welding machine, steel butt welding machine, copper rod butt welding machine

Flash butt welding mainly uses the heat generated by the contact resistance of the workpiece to heat the workpiece, the metal

surface is melted, the temperature gradient is large, and the heat affected zone is relatively small.

The welding seam forms a common grain under the condition of plastic deformation of the counterpart solid phase metal of the

workpiece. The weld structure and composition are close to the base metal (or after heat treatment), and it is relatively easy to

obtain equal-strength and equal-plastic welded joints.

The flashing process has the self-protection function of exhausting air and reducing metal oxidation. Upset forging can also drain

oxides out of the weld with the liquid metal. Weld inclusions, incomplete penetration and other defects are less.

The flashing process has a strong self-adjustment function, and has low requirements for strictly maintaining the specification

and consistency, and the welding quality is stable. Unit welding cross-sectional area requires small electric power, and only

(0.1-0.3) KVA/mm2 electric power is required for welding low carbon steel.

The welding productivity is high, and it only takes a few seconds to tens of seconds to weld a joint.

Welding has a wide range of applications. In principle, all metal materials that can be forged can be welded by flash butt

welding. For example, low carbon steel, high carbon steel, alloy steel, stainless steel and other non-ferrous metals and alloys

can be welded by flash butt welding.

The welding cross-sectional area range is large, generally from tens to tens of thousands of mm2 cross-sectional area can be

welded.

Flash butt welding is widely used in welding various plates, pipes, profiles, solid parts, knives, etc. It is widely used and is

an economical and efficient welding method.

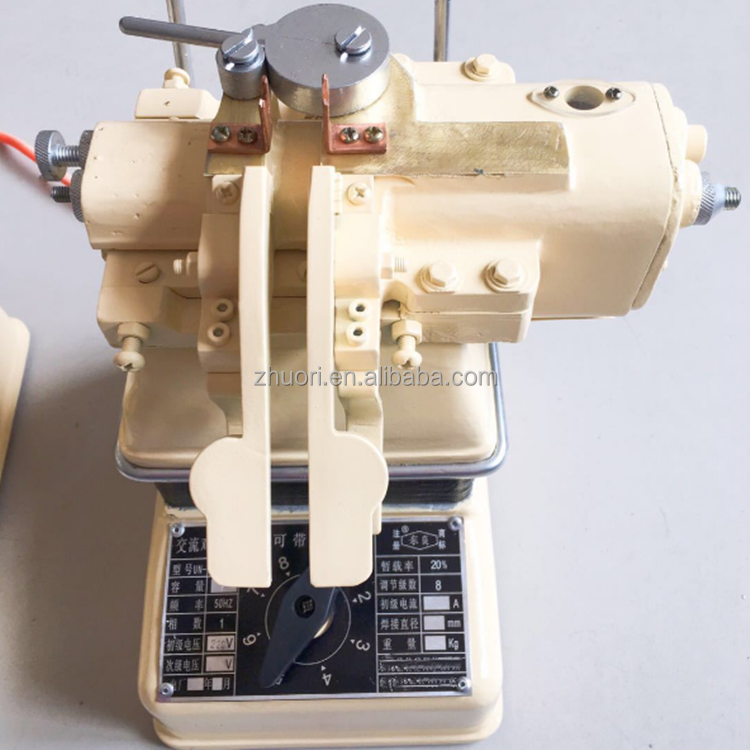

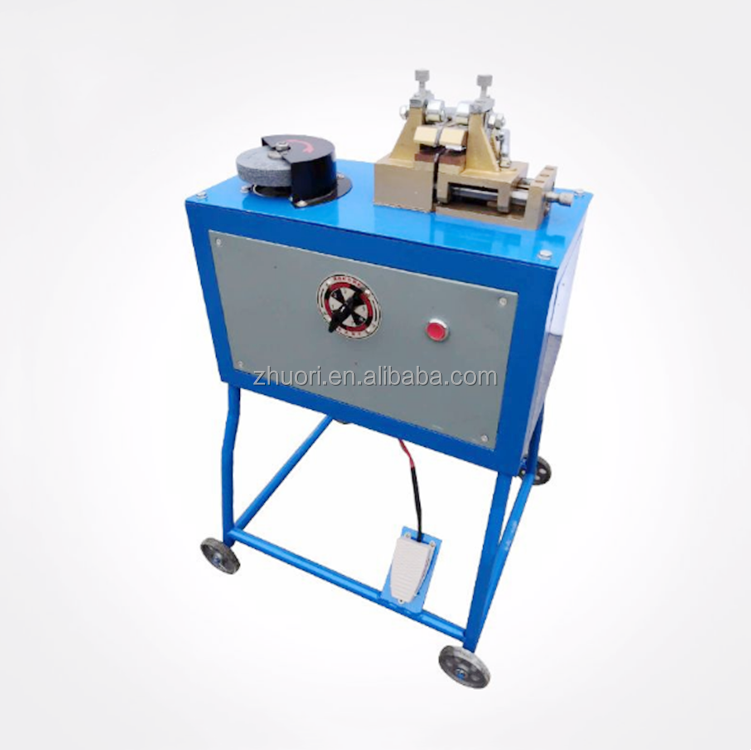

Product show

main Products

Hot Searches