- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

The Nile

-

Dimension(L*W*H):

-

1000*1000*1300mm

-

Weight:

-

800 KG, 1.5t

-

Marketing Type:

-

Hot Product 2022

-

Max feeding size:

-

120mm

-

Output size:

-

≤15mm

-

Motor power:

-

18.5kw

-

Keyword:

-

hammer crusher

-

OEM:

-

yes

-

MOQ:

-

1

-

Color:

-

Customizable

-

Factory Visit:

-

Welcomed Warmly

-

Certification:

-

ISO, CE

Quick Details

-

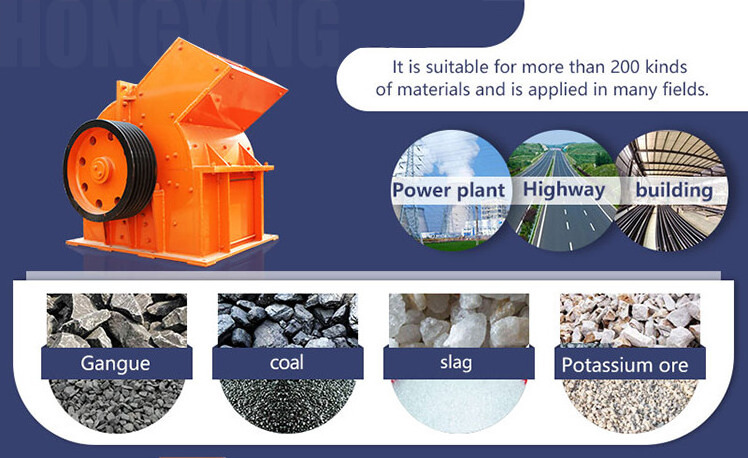

Application:

-

Stone Crusher For Mining

-

Capacity(t/h):

-

1-200

-

Place of Origin:

-

Henan, China

-

Brand Name:

-

The Nile

-

Dimension(L*W*H):

-

1000*1000*1300mm

-

Weight:

-

800 KG, 1.5t

-

Marketing Type:

-

Hot Product 2022

-

Max feeding size:

-

120mm

-

Output size:

-

≤15mm

-

Motor power:

-

18.5kw

-

Keyword:

-

hammer crusher

-

OEM:

-

yes

-

MOQ:

-

1

-

Color:

-

Customizable

-

Factory Visit:

-

Welcomed Warmly

-

Certification:

-

ISO, CE

Product Description

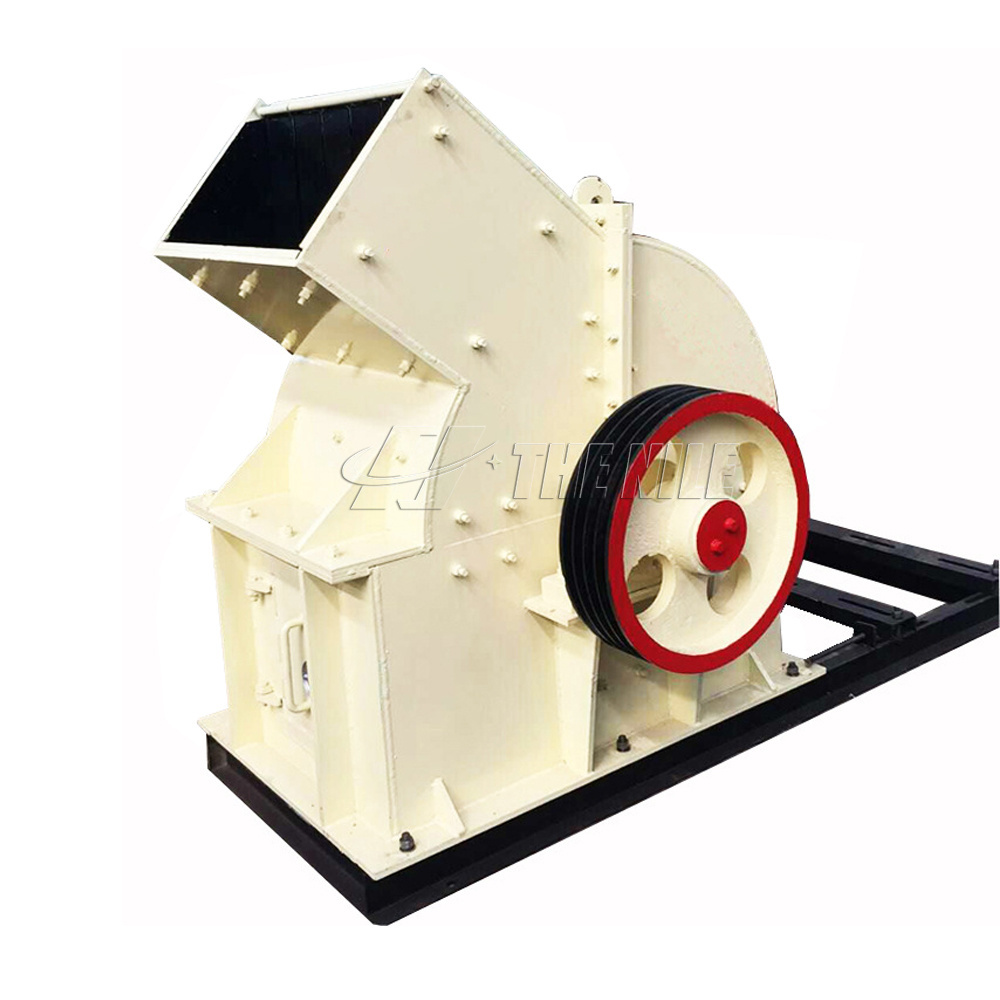

H

ammer crusher for gold mining small rock crusher f

or sale

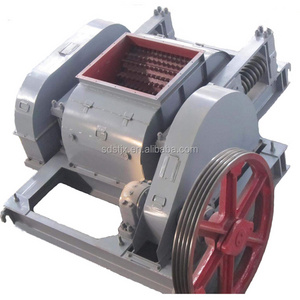

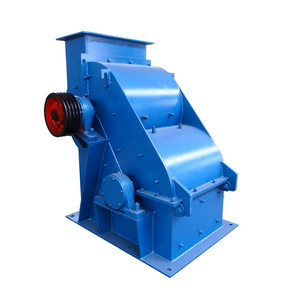

Hammer crusher is the most common of stone crushing equipment. It is also called hammer mill. It has high production capacity, low energy consumption, simple structure, reliable quality, easy maintenance, etc.

Hammer crusher advantages:

1. Working hammer casting with new technology, wear-resistant, and impact-resistant.

2. Output size can adjust according to the customer's request.

3. Beautiful overall design, compact structure, less easily damaged parts, easy maintenance, and other advantages, is an upgraded product.

Overseas Service

1. We have engineers in Kenya, Sudan, Uganda, Professional installation and training skills.

2. We have a factory and warehouse in Kenya and China, Fast pre-sale and after-sale service, Wear Parts in stocks, You can get it soon.

3. Our products have been spread all over China, and also exported to European, American, Asian, African countries. Our sales managers and engineers know the local condition very well, We will supply the most suitable solution for you.

Technical Data

|

Model No.

|

Max. Feeding Size

(mm) |

Output Size

(mm) |

Capacity

(t/h) |

Motor Power

(kw) |

Weight

(t) |

Overall Diemension

L*W*H(mm) |

|

PC400*300

|

100

|

≤10

|

5-10

|

11

|

0.8

|

850*950* 880

|

|

PC600*400

|

120

|

≤15

|

10-25

|

18.5

|

1.5

|

1000*1000*1300

|

|

PC800*600

|

120

|

≤15

|

20-35

|

55

|

3.1

|

1515*2590*1040

|

|

PC1000*800

|

120

|

≤15

|

20-40

|

110

|

7.9

|

3200*2210*1515

|

|

PC1000*1000

|

120

|

≤15

|

30-80

|

132

|

8.65

|

3515*2230* 1515

|

Product Details

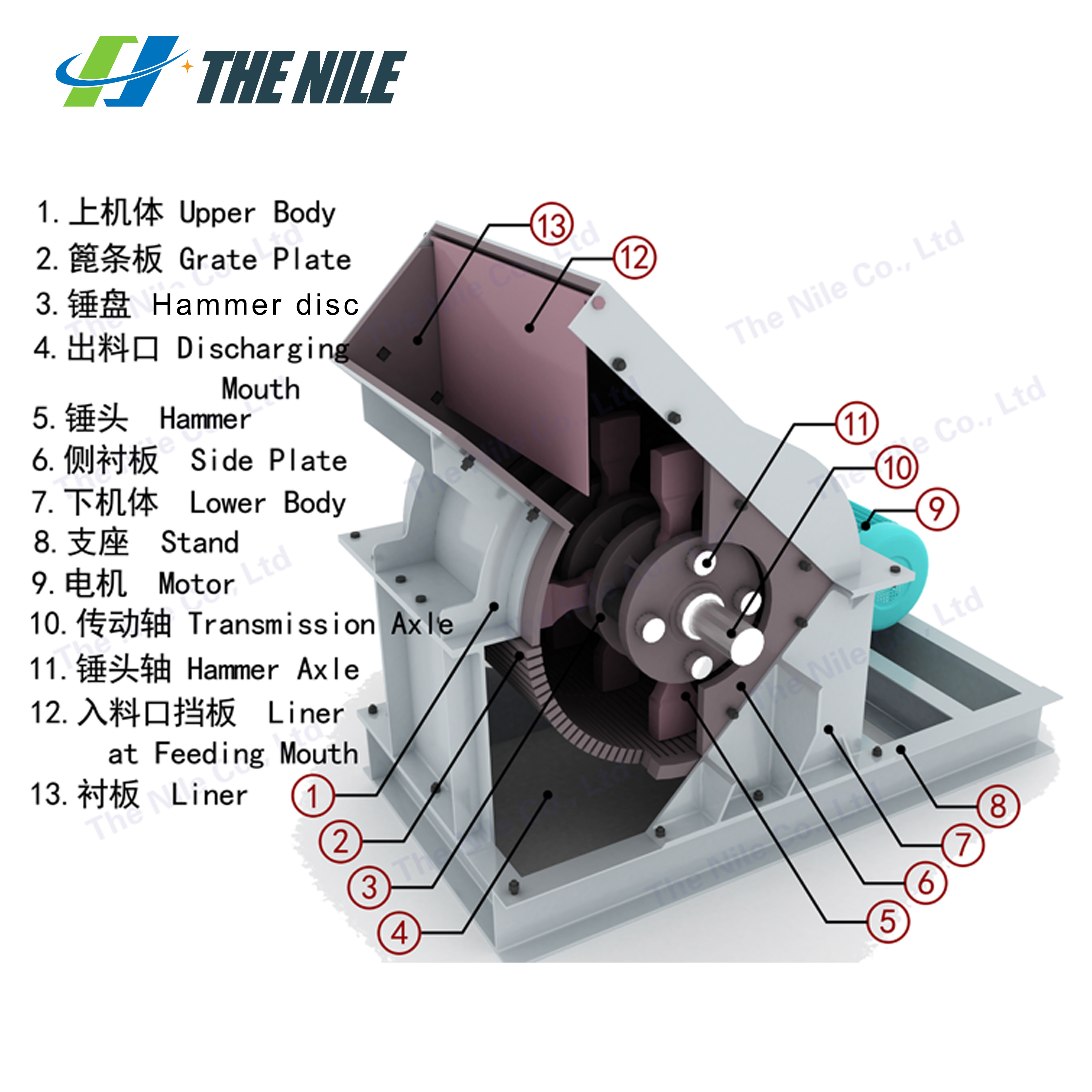

Working principle

:

Motor drives the rotor quickly in the crushing cavity. Raw materials enter the crusher through the feeding inlet and are impacted, cut, and ground by high-speed hammer heads. There is a grate under the rotor assembly, so that materials with size smaller than the grate mesh will be screened out and others are left to be further hammered until they reach the standard size. The size of the final product can be adjusted by changing the grate, the gap between the rotor assembly and the grate can also be adjusted according to different requirements.

Hammners are always operated with sharp edges. And high utilization of hammer head with continuous operation is achieved by reversible rotation. No cleaning in the grinding chamber is required because hammer head with zigzag hammer alignment cleans the grinding chamber automatically.

Wear Parts Supply

:

Customer Site

Overseas Service

1. We have engineers in Kenya, Sudan, Uganda, Professional installation and training skills.

2. We have a factory and warehouse in Kenya and China, Fast pre-sale and after-sale service, Wear Parts in stocks, You can get it soon.

3. Our products have been spread all over China, and also exported to European, American, Asian, African countries. Our sales managers and engineers know the local condition very well, We will supply the most suitable solution for you.

Packing & Delivery

Ways of Packing:

1. Sand blasting, coat with high quality paint;

2. Product wrap by PP-Bubble

3. Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

1. Sand blasting, coat with high quality paint;

2. Product wrap by PP-Bubble

3. Load container, Spear Parts in wooden case.

Transportation:

1. By sea Freight;

2. MSK/MSC/APL/EMC/WANHAI/KLINE

3. We will remind you before boat arrival

Hot Searches