- Product Details

- {{item.text}}

Quick Details

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

xiaoteng

-

Model Number:

-

XT-GZJ-1000

-

Dimension(L*W*H):

-

2200X2100X2200MM

-

Weight:

-

500kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Bottle Filling Capping

-

Filling material:

-

Flowing Liquid

-

Processing Types:

-

Normal Pressure Filling

-

Bottle type:

-

PET Plastic Bottle

-

Warranty:

-

One Year

-

Capacity:

-

2000-30000bph

-

Material:

-

Stainless Steel

-

Usage:

-

Beverage Packaging

-

Certification:

-

CE ISO

Quick Details

-

Packaging Material:

-

Glass, Metal, Paper, Plastic, Wood

-

Voltage:

-

220V/380V

-

Power:

-

1.5kw

-

Place of Origin:

-

Shanghai, China

-

Brand Name:

-

xiaoteng

-

Model Number:

-

XT-GZJ-1000

-

Dimension(L*W*H):

-

2200X2100X2200MM

-

Weight:

-

500kg

-

After-sales Service Provided:

-

Engineers available to service machinery overseas

-

Product name:

-

Bottle Filling Capping

-

Filling material:

-

Flowing Liquid

-

Processing Types:

-

Normal Pressure Filling

-

Bottle type:

-

PET Plastic Bottle

-

Warranty:

-

One Year

-

Capacity:

-

2000-30000bph

-

Material:

-

Stainless Steel

-

Usage:

-

Beverage Packaging

-

Certification:

-

CE ISO

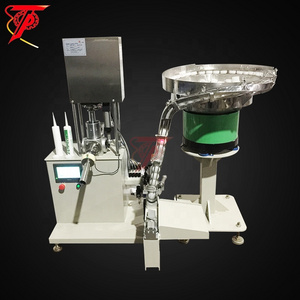

silicone sealant filling machine for silicon gel cartridge packing 310ml

Prosuct Description

PLC and intelligent Touch Screen. Adopt motor forward and reserve motion to adjust the filling volume automatically, it’s very easy to adjust the filling volume. At the same time, there is a micro-adjustment device for each filling cylinder, ensure the filling precision of each container.

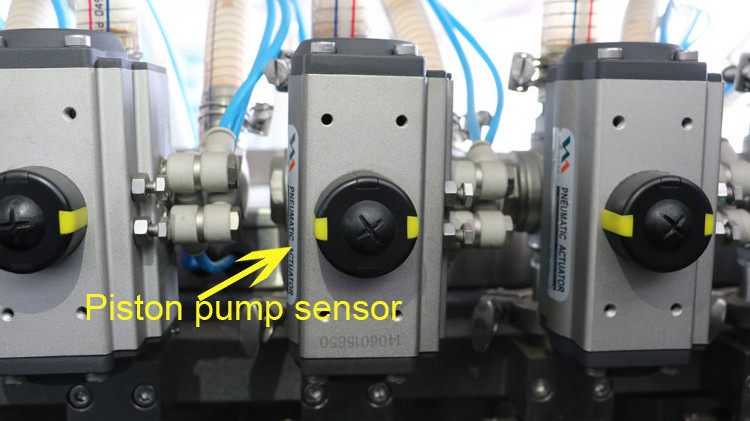

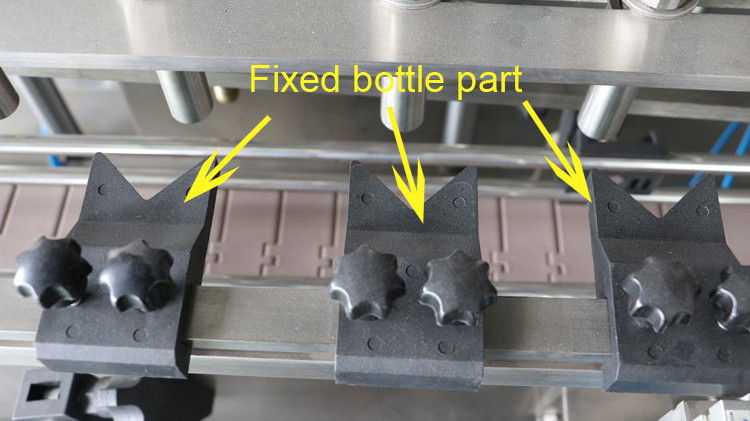

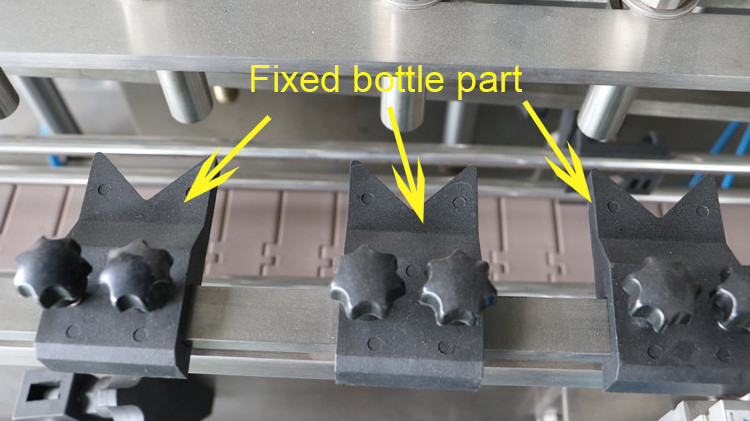

There is individual air collector inside the machine, ensure the stable action of each filling head. Container position will be fixed by air-cylinder, we can adjust the position of filling heads according to the shape of the container, easy to adjust, easy to fix the position, ensure the stable filling action. Drip proof system adopt air-cylinder control, it will plug up the filling nozzle, meanwhile adopts a new patent principle- Vacuum pump back, completely avoid the material leak.

The tank with material detection control system, avoid material overflow, and meanwhile it can keep the material level at the same height, ensure of stable pressure.

Machine Advantages

1,Suitable for various low viscosity material, and various shaped containers

2,Confirm the quantity of the filling heads according to the production capacity requirements.

3,Whole machine made of SUS304, with grace appearance

4, All connections adopt quick release joint, easy to dismantle and maintain, reduce the cost of the use and maintenance, save the time.

5, Adopt single row of material cylinder with quick connection, easy to dismantle the whole cylinder for cleaning or changing the seals inside.

6, Colorful Touch Screen operation panel, can display production station, operation program, filling method and etc. Easy to operate and easy to maintain.

7, We can adjust the filling volume of each filling nozzle individually, to ensure the uniformity of the filling volume.

8, Easy to adjust for different tape and shaped container, 10 minutes can change all the parts.

9, Filling Nozzle with vacuum pumpback function, ensure no leak and drip, avoid pollute the bottle surface.

10, Equip air collector inside the machine, ensure stable air pressure supply, insure high filling accuracy and quality.

Technical Parameters

| Model | XT-GZJ-1000 |

| Filling Head | 1-16(It depends on Customer's filling Speed) |

| Filling Range | 500-5000ml(Can be Adjustable Freely) |

| Capacity | 500-8000BPH |

| Filling Accuracy | ±0.5% |

| Power supply | 220V/380V 50HZ/60HZ |

| Power | 800w |

| Air Supply | 0.4-0.6MPA |

Picture Details

Our Customers

Packing Details

CE Certificates

Contact us