- Product Details

- {{item.text}}

Quick Details

-

Machine Speed:

-

20-120m/min

-

Welding Method:

-

Solid state high frequency straight seam welding

-

Cutting System:

-

Saw blade cutting

-

Pipe Shape::

-

Round, Square, Rectangle, L,T,Z, special...

-

Power(W):

-

According to pipe sizes

-

Weight:

-

According to pipe sizes

-

Color:

-

Customer's Requirement

-

Keyword:

-

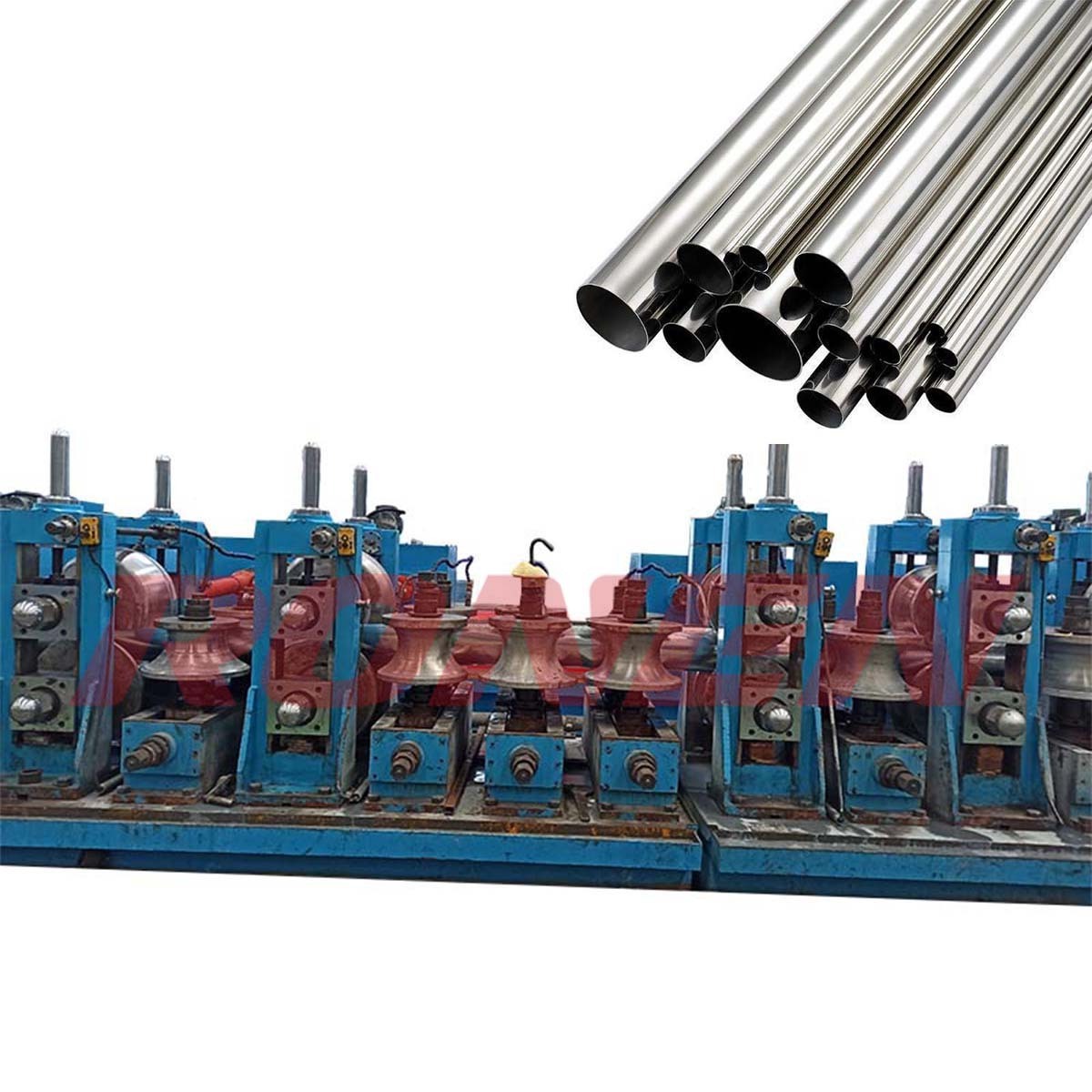

Erw Pipe Mill Line Manufacturer Circular Erw Pipe Mill

-

Control method:

-

A.C inverter regulating

-

Output method:

-

Output method Tracking machine's speed

Quick Details

-

Marketing Type:

-

New Product 2023

-

Place of Origin:

-

China

-

Weight (KG):

-

5000

-

Machine Speed:

-

20-120m/min

-

Welding Method:

-

Solid state high frequency straight seam welding

-

Cutting System:

-

Saw blade cutting

-

Pipe Shape::

-

Round, Square, Rectangle, L,T,Z, special...

-

Power(W):

-

According to pipe sizes

-

Weight:

-

According to pipe sizes

-

Color:

-

Customer's Requirement

-

Keyword:

-

Erw Pipe Mill Line Manufacturer Circular Erw Pipe Mill

-

Control method:

-

A.C inverter regulating

-

Output method:

-

Output method Tracking machine's speed

Steel Pipes Full Automatic Hot-Dip Galvanizing Plant Machine Equipment

1: What kind of pipe can be produced by our ms pipe mill line ?

1.

Oil & Gas Pipes 7. Wire and Cable Protection Pipe

2. Heating Pipe

8. Structural Support Steel Pipe

3. Low-pressure Process Pipeline 9. Industrial Steel Pipes

4. Low Pressure Fire Fighting Pipeline 10. Decoration Pipe

5. Sewage Pipes 11. Water Pipe

6. Steel Scaffolding Pipe 12. Building pipe

|

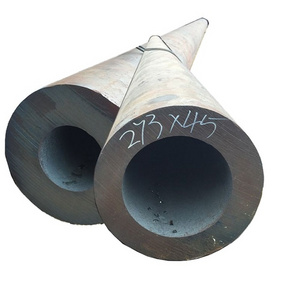

Model |

Specification(mm) |

Thickness (mm) |

Mill Installed Capacity(kw) |

Line Area(m) - programmable |

Working Speed (M/min.) |

|

|

|

Circular |

Rectangular & Square |

|

|

|

|

|

ERW20 |

8-20 |

10mm×10mm -15mm×15mm |

0.5-1.5 |

50KW |

40m*3.8m |

100 |

|

ERW32 |

10-32 |

10mm×10mm -25mm×25mm |

0.3-2.0 |

50KW |

45m*4m |

100 |

|

ERW50 |

20-50 |

15mm×15mm – 40mm×40mm |

0.8-3.0 |

65KW |

50m*4m |

100 |

|

ERW76 |

32-76 |

25mm×25mm – 60mm×60mm |

1.2-4.0 |

120KW |

70m*5m |

100 |

|

ERW89 |

42-89 |

25mm×25mm – 70mm×70mm |

1.5-4.5 |

150KW |

72m*5.5m |

70 |

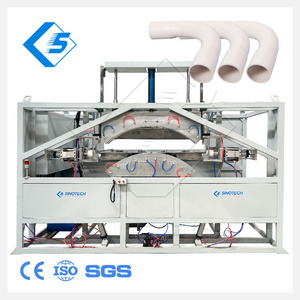

T he a ll-solid-state all-digital IGBT induction heating equipment is mainly used for heating galvanized steel wire. After induction heating, it reaches the heating temperature requirement. The complete induction heating equipment includes induction heating power supply ( i ncluding resonant capacitor, feeding copper bar, pouring inductor, frequency conversion drive, rectifier bridge, inverter bridge and inverter drive part, whole machine). A set of circulating soft water cooling system, heating console, trolly moving system , thermometer, etc.

The efficiency of the power supply is high and the energy saving effect is obvious.

The components are versatile and the whole machine is easy to maintain.

The bridge structure has good flow uniformity.

Full digital circuit, fixed angle control.