- Product Details

- {{item.text}}

Quick Details

-

Heating Power (kW):

-

108 kW

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HEXING

-

Voltage:

-

380v, 220v, 415v, 440v

-

Dimension(L*W*H):

-

24X4.1X2.8m

-

Weight (T):

-

16 T

-

After-Sales Service Provided:

-

Video Technical Support

-

Application:

-

Plastic Food Tray

-

Color:

-

Customer Choice

-

Certification:

-

ISO CE

-

After Warranty Service:

-

Online Support

-

Automatic Grade:

-

Automatic

-

Cutting method:

-

Single/Double cutter

-

Width:

-

640-1040mm

Quick Details

-

Max.Forming Height(mm):

-

60 mm

-

Forming Width (mm):

-

1000 mm

-

Forming Length (mm):

-

1100 mm

-

Heating Power (kW):

-

108 kW

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

HEXING

-

Voltage:

-

380v, 220v, 415v, 440v

-

Dimension(L*W*H):

-

24X4.1X2.8m

-

Weight (T):

-

16 T

-

After-Sales Service Provided:

-

Video Technical Support

-

Application:

-

Plastic Food Tray

-

Color:

-

Customer Choice

-

Certification:

-

ISO CE

-

After Warranty Service:

-

Online Support

-

Automatic Grade:

-

Automatic

-

Cutting method:

-

Single/Double cutter

-

Width:

-

640-1040mm

PRODUCTS DESCRIPTION

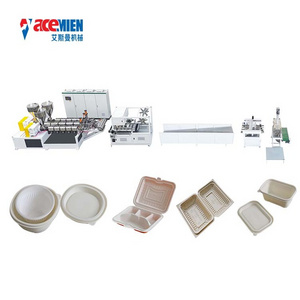

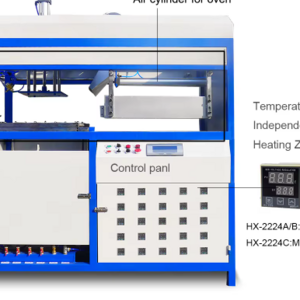

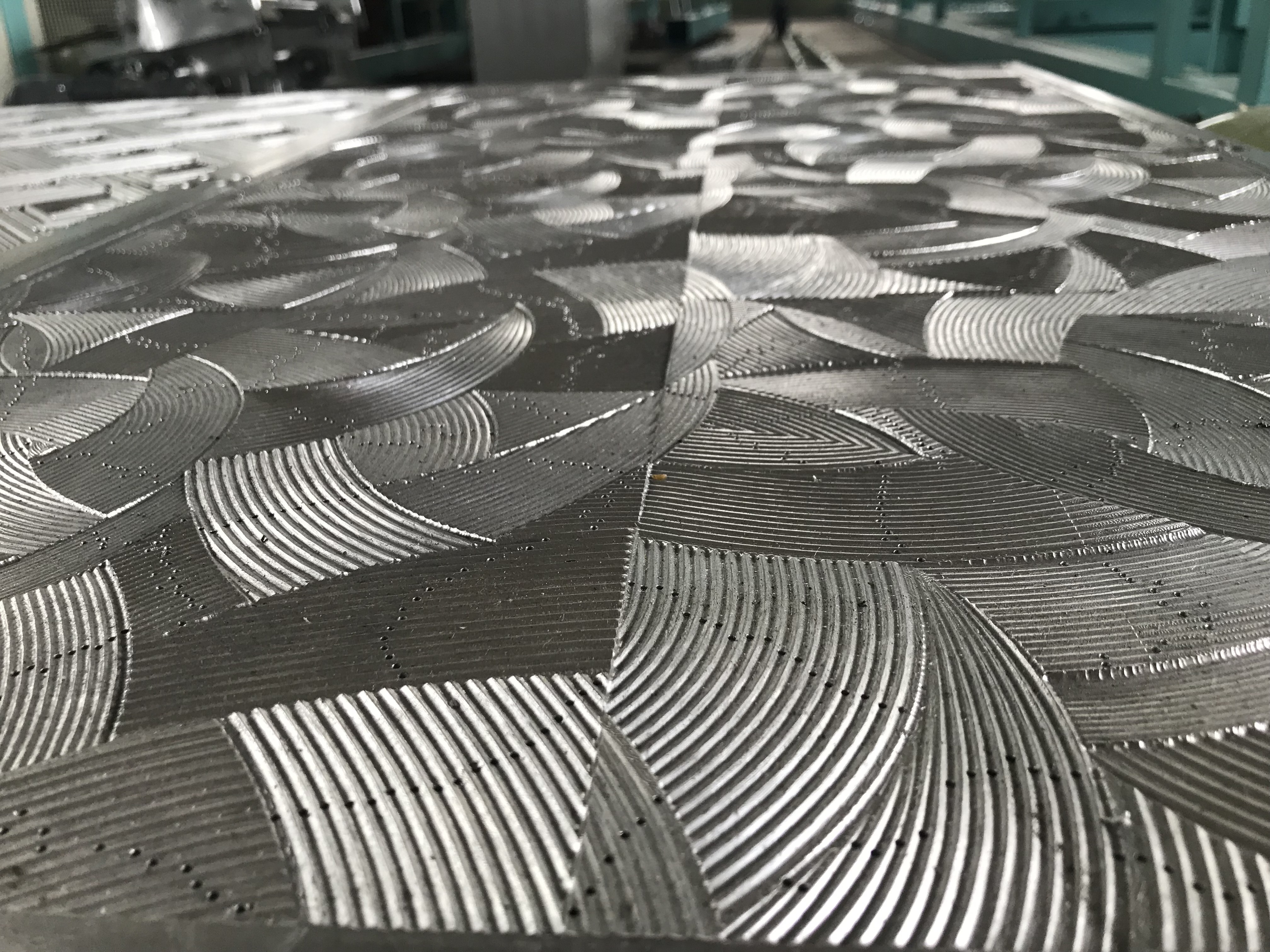

FULLY AUTOMATIC FORMING AND CUTTING INCORPORATED MACHINE

Forming cutting, stacking are done in the same machine, savinglabor, improving efficiency, lowing labor intensity and reducing productioncost Production process is to put foam sheet into forming machine, andproduct and wastage will come out from the rear part. Two workers areenough for the whole production line. It can be used to produce manykinds of materials. Product can be used in the food, medicine, electronicparts, tourism, toys, etc.

|

Model

|

Unit

|

HX-1040

|

|

Max.Forming Area

|

m㎡

|

1000*1100

|

|

Max.Forming Depth

|

mm

|

80

|

|

Production Efficiency

|

s/mould

|

3-5

|

|

Forming Pressure

|

T

|

15

|

|

Heating Power

|

kw

|

108

|

|

Total Power

|

kw

|

168

|

|

Total Weight

|

T

|

16

|

RECOMMEND PRODUCTS

COMPANY PROFILE

CUSTOMER PHOTO

COOPERATION BRAND

SERVICE PROCESS

FAQ

Q1.What materials are needed for equipment production?

A1:pe machine: polyethylene, talc powder, GMS, liquid butane.

ps machine: polystyrene, talc powder, liquid butane.

If you want to produce color products, you also need to use color master.

Q2.How long is the production cycle of the equipment?

A2:The production cycle is determined according to the equipment model, quantity and workshop production tasks.

The minimum equipment cycle is about 20-30 days.

Q3.Minimum order quantity?

A3:Our minimum order quantity for equipment is 1 set.

Q4.When can I get a quote?

A4:We usually quote within 24 hours of receiving your inquiry. If you need a price very urgently, please call us on email so we will give priority to your inquiry.

Q5.Can I put my logo on the packaging?

A5:Yes, we can do OEM service, but you need to send us your packaging and logo design.

Q6.What kind of payment do you accept?

A6:T/T, L/C at sight, cash

A1:pe machine: polyethylene, talc powder, GMS, liquid butane.

ps machine: polystyrene, talc powder, liquid butane.

If you want to produce color products, you also need to use color master.

Q2.How long is the production cycle of the equipment?

A2:The production cycle is determined according to the equipment model, quantity and workshop production tasks.

The minimum equipment cycle is about 20-30 days.

Q3.Minimum order quantity?

A3:Our minimum order quantity for equipment is 1 set.

Q4.When can I get a quote?

A4:We usually quote within 24 hours of receiving your inquiry. If you need a price very urgently, please call us on email so we will give priority to your inquiry.

Q5.Can I put my logo on the packaging?

A5:Yes, we can do OEM service, but you need to send us your packaging and logo design.

Q6.What kind of payment do you accept?

A6:T/T, L/C at sight, cash

Hot Searches