- Product Details

- {{item.text}}

Quick Details

-

Pipe shape:

-

round

-

Raw material:

-

Alloy Steel

-

Usage:

-

Construction Pipe

-

Color:

-

Customer's Requirement

-

Thickness:

-

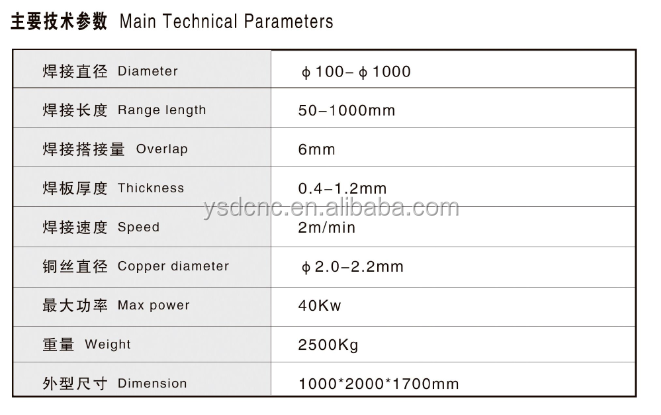

0.4-1.2mm

-

Pipe diameter:

-

100-1000mm

-

overlap:

-

6mm

-

range length:

-

50-1000mm

-

Weight:

-

2500kg

-

Power(W):

-

40kw

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Name:

-

Stitchwelder

-

Material:

-

Stainess Steel

-

Pipe shape:

-

round

-

Raw material:

-

Alloy Steel

-

Usage:

-

Construction Pipe

-

Color:

-

Customer's Requirement

-

Thickness:

-

0.4-1.2mm

-

Pipe diameter:

-

100-1000mm

-

overlap:

-

6mm

-

range length:

-

50-1000mm

-

Weight:

-

2500kg

-

Power(W):

-

40kw

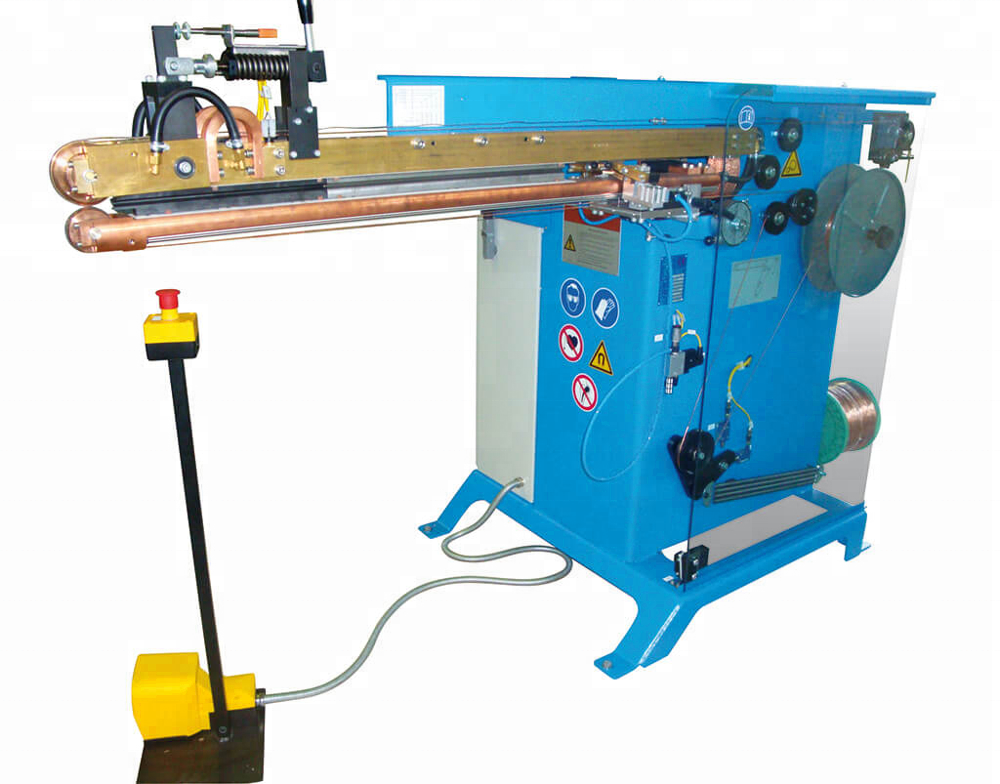

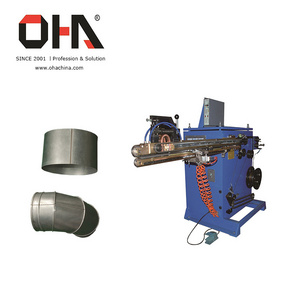

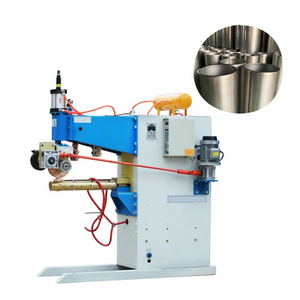

Stainless steel circular duct pipe air straight seam welding Stitch Welder machine

YSD duct production machines are: automatic duct production line, CNC Angle steel flange production line, double (single )linkage TDF flange machine , Angle code mould, plasma cutting machine, seven functions locking machine, manual ( pneumatic ) crimping machine, five line s ( seven lines ) beading machine, Angle crimping machine, reel shear beading machine ,leveling bending machine,steel-bend type,horizontal shrimp bend machine,pneumatic joint machine, Angle setter ,bias samsung rolling machine.

|

Company Name (manufacturer): Nanjing Shanduan CNC Machine Tool Co., Ltd. |

|

Brand: YSDCNC |

|

Address: MINGJUR INDUSTRIAL CONCENTRATION DISTRICT,SHIQIU TOWN,LISHUI AREA,NANJING,JIANGSU |

|

Tel : +86 025-57262305 Phone : +86 18851629789 |

|

WhatsApp/Skype /Wechat : +86 18851629789 |

|

Website: www. ysdcnc. com |

Stitchwelder

Performance Features:

The new generation of our Stitchwelder builds upon the most reliable and recognized Stitchwelder 1000/1270/1540 in the industry.

The guaranteed air-tight seam can be achieved through stitch welding or continuous welding application. Moreover,

YSDCNC

is emphasizing its leading role in the HVAC industry by equipping the Stitchwelder with a user-friendly touchscreen. This industrial novelty serves to facilitate the production set up and allows the user to save program settings.

The Stitchwelder also features the fastest welding speed in the industry with up to max. 15 m/min., underlining the continuous productivity and efficiency of the machine. Naturally, the welded seam is constant from the beginning to the end, sealing or paint cover is not required, no need to clean or rework the welding rolls, and eliminating burnt galvanized coating results in less finishing work. Finally, the 6 to 8 mm overlap keeps your material costs at a minimum.

Stitchwelder