- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

/

-

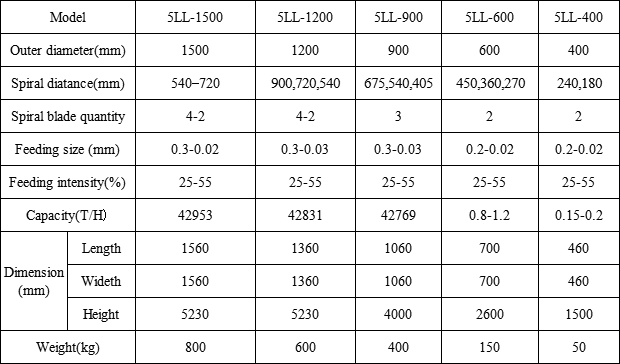

Dimension(L*W*H):

-

1560*1560*5230mm

-

Weight:

-

600 KG

-

Product name:

-

Spiral Concentrator

-

Application:

-

Ore

-

Installation:

-

Engineer Guide

-

Capacity:

-

6-8 Tons/hour

-

Feeding size:

-

0-2mm

-

Material:

-

Fibergrass

-

Market:

-

Global

-

Price:

-

Negotiation

-

Local Service Location:

-

None

-

Certification:

-

ISO9001:2008

Quick Details

-

Production Capacity:

-

98%

-

Place of Origin:

-

China

-

Brand Name:

-

JINCHUAN

-

Voltage:

-

/

-

Dimension(L*W*H):

-

1560*1560*5230mm

-

Weight:

-

600 KG

-

Product name:

-

Spiral Concentrator

-

Application:

-

Ore

-

Installation:

-

Engineer Guide

-

Capacity:

-

6-8 Tons/hour

-

Feeding size:

-

0-2mm

-

Material:

-

Fibergrass

-

Market:

-

Global

-

Price:

-

Negotiation

-

Local Service Location:

-

None

-

Certification:

-

ISO9001:2008

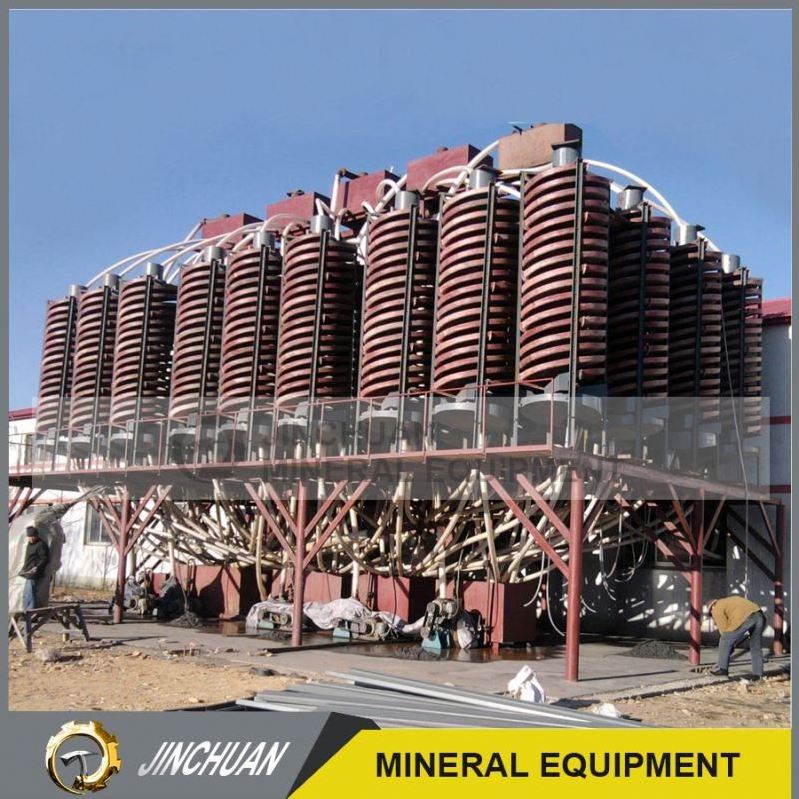

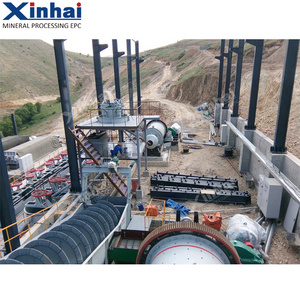

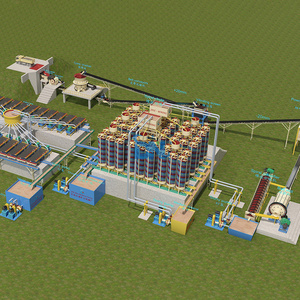

Introduction

Spiral concentrator is our company's concentrating experienced scientific product, which is the best concentrating equipment, especially for concentrating sand ore in beach, riverside, seashore and stream.The product is made of the fiberglass lined with wear resistant resin and emery cover; the advantages are light, moisture proof, anti rust, wear proof, anti corrosion and no noise, properly suitable for the different feeding particle sizes and grades. It is the domestic advanced level, the new highly effective equipment.

Main Features

1.Reasonable structure and small occupation area

2.High recovery, high efficiency, and precise separation,

3.Light in weight, rust and corrosion resistant;

4.Simple installation and Minimal maintenance requirements

5.Low operating cost and long operating life

6.Reliable running with minimal operator attention

7.Strong adaptability to fluctuation of feeding amount, density, size and grade;

Working principle

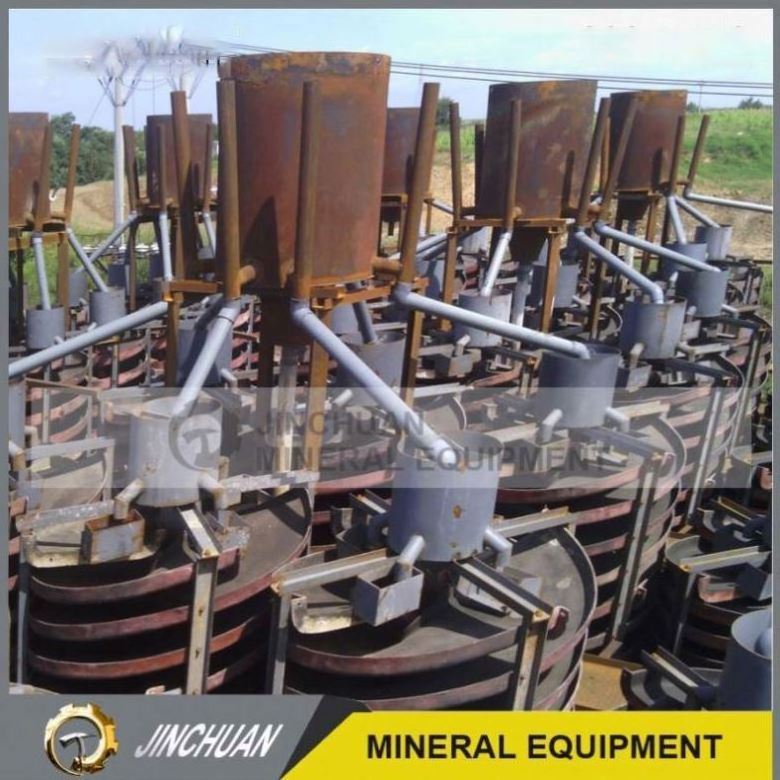

Spiral Chute is working under the the force of water flow, gravity, inertial centrifuge and friction. Slurry is pumped to the top of the spiral , and it enters a feed distributor that evenly distributes the feed to each spiral concentrator. The design and shape of the spiral make it work, when combined with gravitational acceleration. As the slurry travels the spiraling path down the spiral, mineral grains settle and start sorting according to size, density and to a lesser extend shape. Low density particles arecarried with the bulk of the water towards the outside of the spiral , while particles with the greatest density migrate towards the inside of the spiral.

Main Features

Normally, one set spiral concentrator has four starts, each starts has four or five turns.therefore,when ore come into the spiral chute, we use the distributor tank

Applications

Iron ore, chromite and manganese beneficiation

Tin, tantalum and ore concentration

Gold, native copper and base metal recovery

Silica sands processing

Pre-Sales Service

* Inquiry and consulting support.

* Sample testing support.

* View our Factory.

After-Sales Service

* Training how to instal the machine, training how to use the machine.

* Engineers available to service machinery overseas.

100% Response Rate

100% Response Rate

100% Response Rate