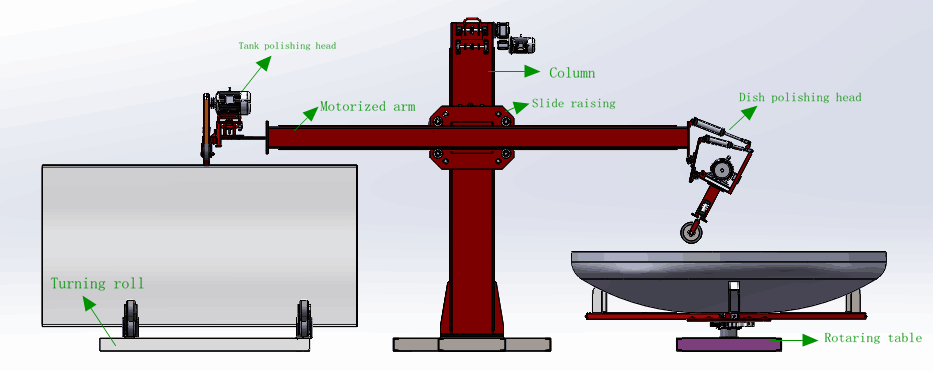

1, Column (moving stroke 1600mm), motorized arm (moving stroke 3000mm), slide raising drive mechanism and other components.

2, Column, arm material respectively 500x300x10mm, 250x150x8mm square tube.

3, Arm driven by a gear, rack and reducer; column driven by sprocket, chain and reducer.

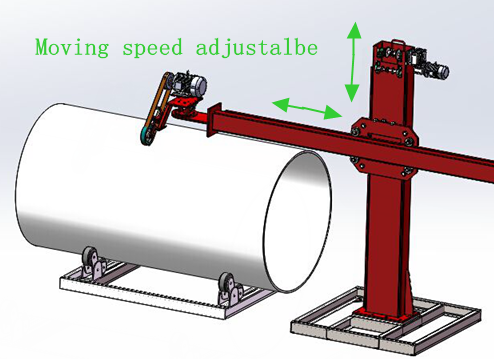

4, Arm moving speed( up and down,right and left movement) is adjustable frequency by variable-frequency drive.