- Product Details

- {{item.text}}

Quick Details

-

Weight:

-

1100 KG

-

Machine type:

-

Automatic Digital Collator Machine

-

After Warranty Service:

-

Video technical support

-

Certification:

-

ISO9001

-

Product name:

-

Paper Collator Machine

-

Function:

-

Collating,Gathering

-

Advantage:

-

High Efficency

-

Suitable Materials:

-

Paper Material

-

Application:

-

Printing Company

-

Paper Thickness:

-

50-400gsm

-

Finished Products:

-

Board Book

Quick Details

-

Type:

-

Paper Sheet Feeding Collating Machine

-

Place of Origin:

-

Zhejiang, China

-

Voltage:

-

380V/50Hz

-

Weight:

-

1100 KG

-

Machine type:

-

Automatic Digital Collator Machine

-

After Warranty Service:

-

Video technical support

-

Certification:

-

ISO9001

-

Product name:

-

Paper Collator Machine

-

Function:

-

Collating,Gathering

-

Advantage:

-

High Efficency

-

Suitable Materials:

-

Paper Material

-

Application:

-

Printing Company

-

Paper Thickness:

-

50-400gsm

-

Finished Products:

-

Board Book

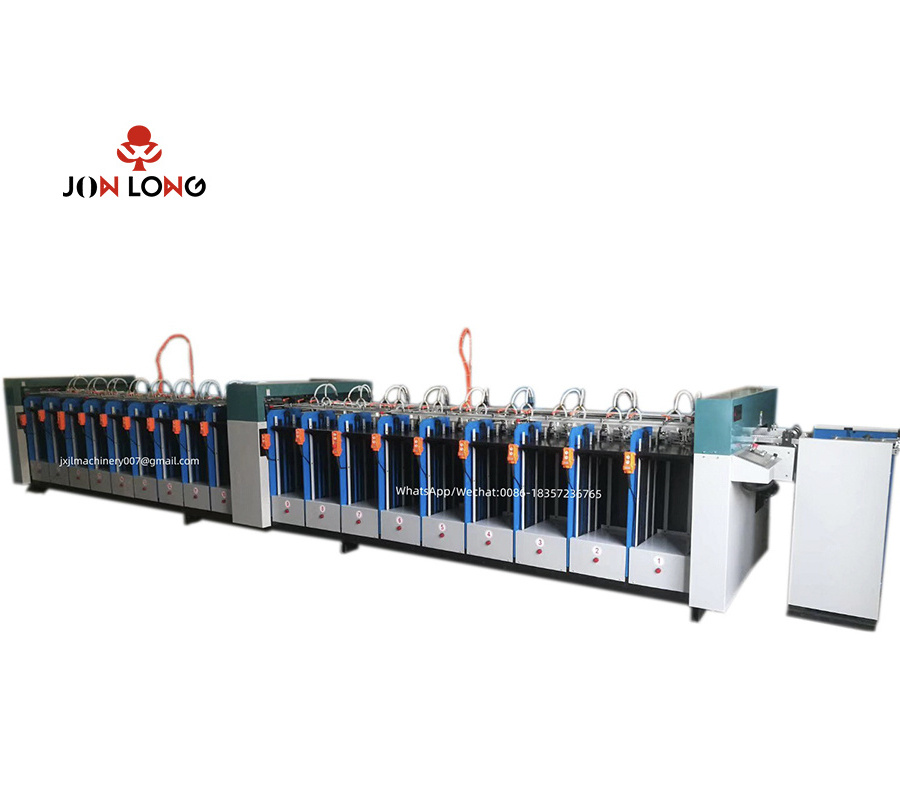

XP6-440 Automatic Book Paper Collator Machine Calendar Sheet Collator Gathering Machine

Paper sheet feeding collating machine can be customized, mainly the realization of the calendar, calendars, single, magazines, brochures, peritoneal paper, carbon paper, carbon paper, writing paper, cardboard, paper and plastic paper, wallpaper, PP and irregular shape of the paper page. The device is compact, small footprint, touch screen, man-machine dialogue, advanced paper detection function, automatic tension, double alarm. Adopt Ultrasonic to checking " feeding double piece of paper".

Technical parameters:

| Max.paper size | 860x580mm (Can be customized) |

| Min.Paper size | 180x120mm (Can be customized) |

| Paper thickness | 50-400gsm |

| Max.Loading height | 480mm |

| Speed | 1200-1800decks/hour |

| Drive motor | 380v, 1.5kw |

| Servo motor | 220v,1.1kw |

| Paper rubbing motor | 220v,90w |

| Air Pump motor | 380v,4kw |

| Vibrator motor | 220v,60w |

| Working voltave | 380v,3phase 4lines |

| Paper-laying method | Vertical and horizontal paper feeding |

1.The automatic paper collating gathering has compact structure, small footprint. Each station can be customized to set the number, according to the needs of each work.

2. Advanced PLC touch screen control.

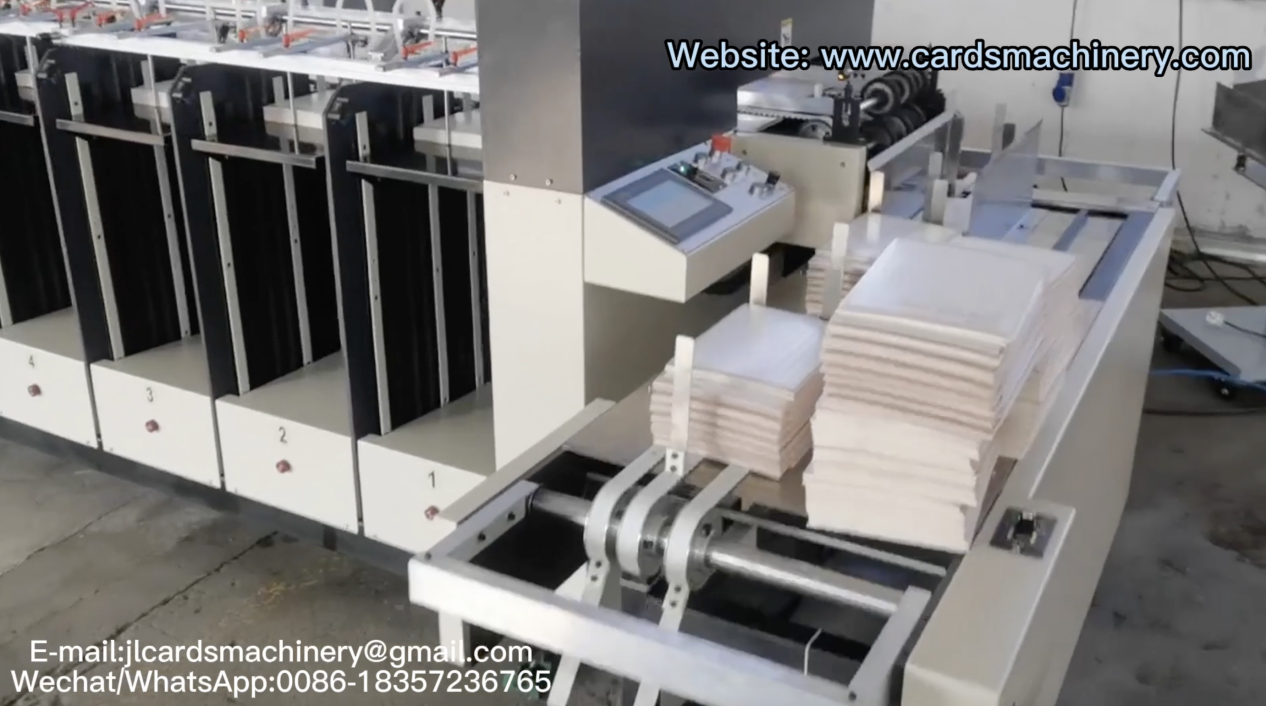

3.The way of receiving paper has neat receiving paper, and staggered receiving paper.

4. Paper feeding in vertical direction and paper carried in horizontal direction by accurate timing belt conveying device. Paper are collected by vibration to ensure the tidiness of final collated pages.

5. S tations with Ultrasonic to checking " feeding double piece of paper". Equipped with highly advanced paper detection device such the missing page be automatically filled, double sheet alarm device etc.

6.Each station is equipped with air blowing and paper separation to prevent sticking.

Please don’t hesitate to contact me for any other questions. Thank you!

WeChat/WhatsApp:0086-18357236765

S tations with Ultrasonic to checking " feeding double piece of paper".

Optional receiving paper methods (Default Neat Receiving Paper)

Neat Receiving Paper

Staggered Receiving Paper