- Product Details

- {{item.text}}

Quick Details

-

Weight (KG):

-

1000 KG

-

Product name:

-

Tyre Shredder Waste Tire Recycling Production Line

-

Color:

-

Clients' Demand

-

shaft design:

-

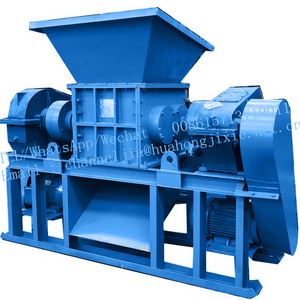

double shaft

-

motor brand:

-

Siemens

-

motor power:

-

15+15kw;22+22kw

-

capacity:

-

100-2500kg

-

weight:

-

3000-5000kg

-

power source:

-

380v 50hz

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support

-

Keyword:

-

Tire Shredder Rubber Crusher

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Wanrooe

-

Power (kW):

-

180 kW

-

Weight (KG):

-

1000 KG

-

Product name:

-

Tyre Shredder Waste Tire Recycling Production Line

-

Color:

-

Clients' Demand

-

shaft design:

-

double shaft

-

motor brand:

-

Siemens

-

motor power:

-

15+15kw;22+22kw

-

capacity:

-

100-2500kg

-

weight:

-

3000-5000kg

-

power source:

-

380v 50hz

-

After-sales Service Provided:

-

Engineers available to service machinery overseas, Video technical support

-

Keyword:

-

Tire Shredder Rubber Crusher

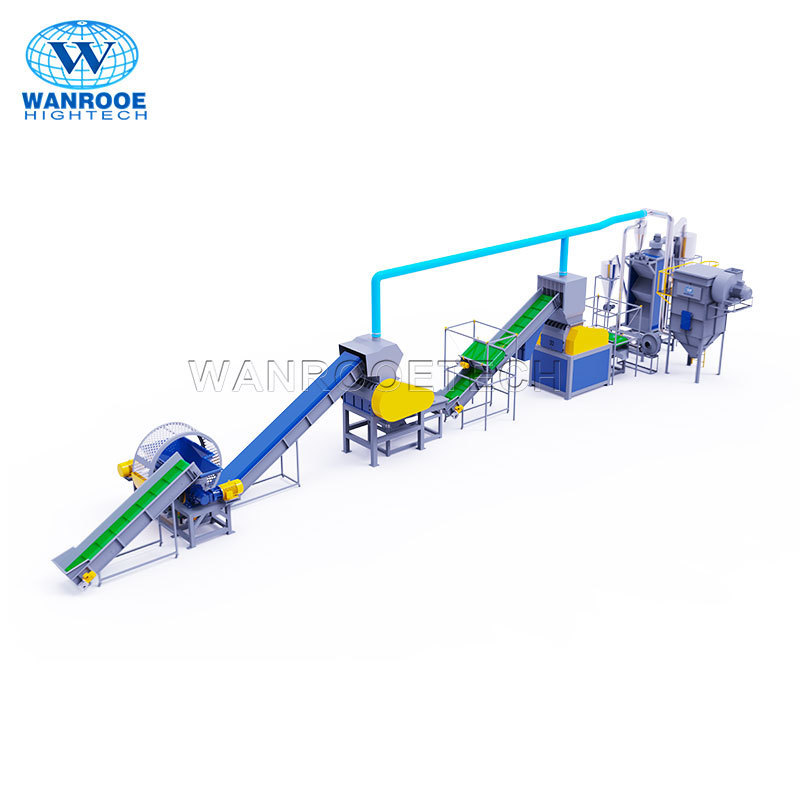

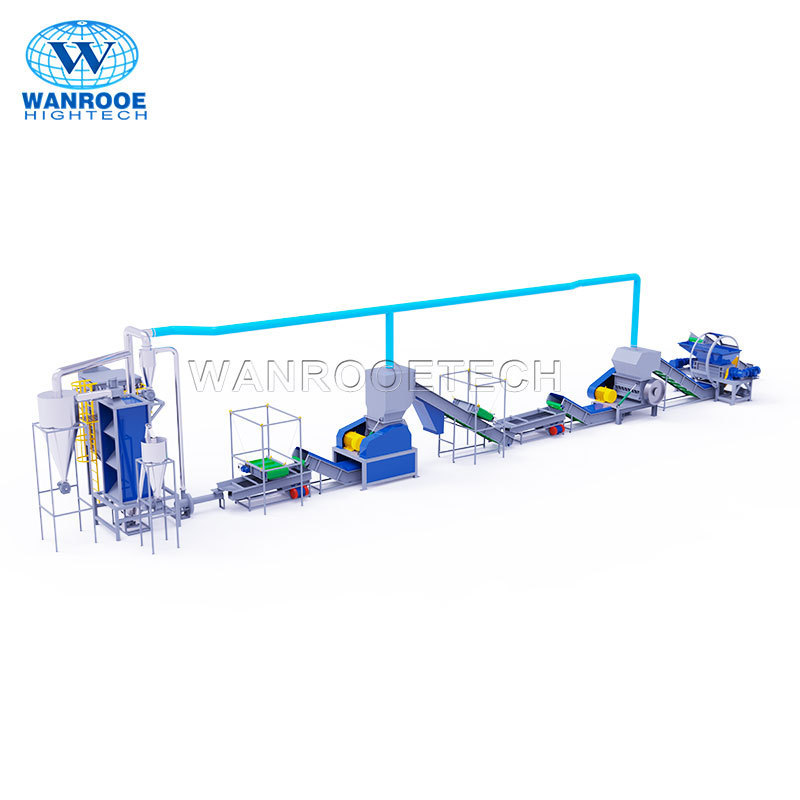

Tyre Shredder Waste Tire Recycling Production Line

Application Areas:

1.Paving sport ground:Runway, school sporting field, garden path, bowling alley, pavement, recreation field, basketball field, etc.

2.Automobile industry:Train’s floor, disc silk ribbon for braking, soleplate of automobile and truck, shake sleeve, seal stripe, buffer, shock absorber, daily material for ocean shiping, tyres and inner unerlay of tyres, etc.

3.Architecture and equipment:Adhensive/sealant, floors of hospital, company, insulated rubber material, carpet cushion, grass cushion for family animal, extruded products, module products, coating, bricks, thin slice, water-proof material, etc.

Description:

With the rapid development of the world automobile industry and transportation industry, the demand of all kinds of tires are increasing day by day.So the waste tire problem has become serious to environment. How to dispose the waste tires also become more and more important in every countries.The rubber powder production line is a new innovative equipment. Rubber powder production line is used for processing used tires and rubbers to fine rubber powders.End products size can reach 30-120 mesh free of steel wire and fiber.

Waste rubber powder production line consists of tire broken machine host and auxiliary machine two parts.Auxiliary equipment:Hook Wire Drawing Machine,Tire Cutter Machine(Optional according to tire size),Conveyor, Magnetic Separator Machine,and other components.

Technical Features:

1.To granulate waste tires into fine rubber powder with steel and fiber completely recycled at ambient temperature.

2.High purity of rubber powder is 99%.

3.Low energy consuming and good performance-cost ratio.

4.High autoimmunization, fewer labors requirement.

5.Unique design, high output and long service time.

6. In line have dust remover, equipment running pollution-free, meeting the environmental requirement of the government.

7.It is controlled by automatic PLC, with easy operation and high efficiency

9.Our tire shredders Use a planetary reducer, not a traditional gearbox, and the planetary gearbox has the following advantages:High Efficiency,Greater Stability,Compact Size,Higher Torque Density,Cost Effective Precision,High Radial Loads.

Process Flow:

| NO | Process | Machine | Description |

| 1 | Pull the steel wire out of tire | Tire Wire Drawing Machine | Tire Wire Drawing Machine can pull the steel from bear inside the tire completely, then, the tyre will be easy crushed and cut. |

| 2 | Cut the tire(Optional) | Tire Cutter Machine | If the tire size is too large,you can use the Tire Cutter Machine to Pre cut it. |

| 3 | Shred tire into block | Tire Shredder | Tire shredder can be used to shred used tyre into 25mm to 152mm(1”-6”) rubber chip. |

| 4 | Break the rubber block smaller and separate the steel wire | Tire Crusher | Special tire scraps crushing blades,can separate the truck scraps steel wire easily. |

| 5 | Strong Magnetic Separator to remove the steel wire( first time) | Magnetic Separator | Separate steel wire from rubber. |

| 6 | Grind the rubber block into powder | Rubber Miller | Grind rubber powders to 30-120 Mesh free of steel wire and Fiber. |

| 7 | Strong Magnetic Separator to remove the steel wire( second time) | Magnetic Separator | Remove any remaining fine wire. |

| 8 | Separate rubber powder and fiber | Fiber separating System | The main application of classifier is to divide input powder into light and heavy parts under the conditions of negative pressure and sealing. |

|

Model |

Shreddering Motor Power (kw) |

Shreddering Chamber size(mm) |

|

PNSS-300 |

7.5 |

510×300 |

|

PNSS-400 |

7.5 |

510×400 |

|

PNSS-600 |

7.5+7.5 |

510×600 |

|

PNSS-800 |

18.5+18.5 |

600×800 |

|

PNSS-1000 |

22+22 |

800×1000 |

|

PNSS-1200 |

30+30 |

1000×1200 |

|

PNSS-1400 |

55+55 |

1400×1200 |

|

PNSS-1600 |

55+55 |

1600×1200 |

|

PNSS-1800 |

75+75 |

1800×1400 |

|

PNSS-2000 |

90+90 |

2000×1400 |