- Product Details

- {{item.text}}

Quick Details

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

customized

-

Weight:

-

1-10 TON

-

Product name:

-

Mobile Gold Trommel

-

Keywords:

-

Gold Washing Machine

-

Other name:

-

Gold Trommel Wash Plant

-

Application:

-

Alluvial Gold Washing

-

Usage:

-

Gold Wash & Screen

-

Screen size:

-

3-10mm

-

Recovery rate:

-

95-99%

-

Feature:

-

Simple Operation

-

Advantage:

-

Portable, Diesel generator

-

After sale service:

-

Life Long Gurantee

-

Certification:

-

ISO9001

Quick Details

-

Production Capacity:

-

100

-

Place of Origin:

-

Jiangxi, China

-

Brand Name:

-

HENGCHENG

-

Voltage:

-

380v

-

Dimension(L*W*H):

-

customized

-

Weight:

-

1-10 TON

-

Product name:

-

Mobile Gold Trommel

-

Keywords:

-

Gold Washing Machine

-

Other name:

-

Gold Trommel Wash Plant

-

Application:

-

Alluvial Gold Washing

-

Usage:

-

Gold Wash & Screen

-

Screen size:

-

3-10mm

-

Recovery rate:

-

95-99%

-

Feature:

-

Simple Operation

-

Advantage:

-

Portable, Diesel generator

-

After sale service:

-

Life Long Gurantee

-

Certification:

-

ISO9001

trommel screen alluvial gold mining machine Small Gold Washing Plant

General D escription

The gold trommel ( small gold washing plant ) is a specialized piece of placer mining equipment that is most commonly used in commercial gold mining operations. When employed commercially, trommels can be quite large in scale and are often powered by large diesel or electric engines.

Machine Features

The small gold washing plant trommels are very efficient gold grabbers and even extremely fine or flour gold in the micron range can be recovered consistently using a properly constructed trommel that is set up for peak operation. Additionally, like a highbanker, trommels can be set up anywhere near the source of auriferous material, as long as water can be pumped or "fed" into the drum unit and there is a power source to operate the unit.

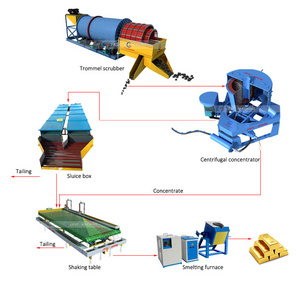

Machine Components

How the trommel works

1) The small gold washing plant

trommel is first set up at or near the

the

auriferous material to be processed.

2) It is then energized, the motor begins turning the rotating drum, and the water sprayer is activated.

3) Material is fed into the hopper box and directed into the angled and constantly turning drum.

4) The sprayer then washes or "cleans" dirt and mud from the material as it tumbles round and round inside the drum.

5) Any pieces of material (rocks and gravel) larger than the drum screen hole size will eventually be forced down the drum into the tailings tray and out, forming a tailings (coarse tailings) pile at the bottom of the unit.

6) The remainder of the gold-bearing gravel will fall into the sluice box below, where hydraulic action traps the black sands and gold while allowing the remaining waste to flow out the lower end of the box into additional tailings (fine tailings).

7) The entire process is repeated until the sluice box requires "cleaning."

8) The trommel is then shut down and all the black sand concentrates and gold are flushed from the sluice box into a container/tank.

9) The concentrates are then panned or run through a shaker table, and the gold recovered.

Technical Data

|

Model |

Capacity (t/h) |

Power (kw) |

Drum Dia (mm) |

Drum Len g th (mm) |

s creen mesh Size (mm) |

Dimension (mm) |

Weight ( T ) |

|

GT0510 |

1- 10 |

1.5 |

500 |

1000 |

<3~10 |

1800*1020*1500 |

1.0 |

|

GT1015 |

5- 20 |

4.0 |

1000 |

1500 |

3000*1400*2145 |

2 . 2 |

|

|

GT1020 |

1 0 - 40 |

5.0 |

1000 |

2000 |

3460*1400*2145 |

2 . 8 |

|

|

GT1225 |

2 0 - 60 |

7.5 |

1200 |

2500 |

4146*1600*2680 |

4 . 2 |

|

|

GT1530 |

3 0 - 90 |

11 |

1200 |

3000 |

4460*1900*2820 |

5 . 1 |

|

|

GT1545 |

50- 120 |

15 |

1500 |

4500 |

5960*1900*3080 |

6 . 0 |

|

|

GT1848 |

80- 20 0 |

22 |

1800 |

4800 |

6500*2300*4000 |

7 . 5 |

|

|

GT2055 |

120- 25 0 |

30 |

2000 |

5500 |

7500*2500*4000 |

8 . 6 |

Machine Details Show (GT0715 Model)

Hengcheng company is dedicated to provide a complete line of equipment including shaking table, spiral chute, jig machine,trommel,rotary scrubber, flotation machine, magnetic separator,grinding mill, and so on. We are involved in the range of mineral beneficiation services including mineral testing, process flowchart design, installation and commissioning, technical co nsult ing, as well as staff training,etc. Our proven technologies and experience permit us to provide every customer with the most effiicent & commercial beneficiation plant equipment.

|

If you are interested in our products,welcome to contact us. ↓↓↓ |