- Product Details

- {{item.text}}

Quick Details

-

Model Number:

-

UT-M

-

Product name:

-

Plastic Injection Molding

-

Material:

-

45#,P20 steel,NAK80,718H,SKD

-

Design software:

-

Solid Works 2009 CAD Software

-

Runner:

-

Cold Runner

-

Mould base:

-

LKM,HASCO,and so on

-

Weight:

-

depending on your size requirement

-

Mould life:

-

Can up to 500,000 shots

-

Cavity:

-

Multi Cavity

-

Packing method:

-

Film and Wooden case

Quick Details

-

Shaping Mode:

-

Plastic Injection Mould

-

Place of Origin:

-

China

-

Brand Name:

-

U TECH

-

Model Number:

-

UT-M

-

Product name:

-

Plastic Injection Molding

-

Material:

-

45#,P20 steel,NAK80,718H,SKD

-

Design software:

-

Solid Works 2009 CAD Software

-

Runner:

-

Cold Runner

-

Mould base:

-

LKM,HASCO,and so on

-

Weight:

-

depending on your size requirement

-

Mould life:

-

Can up to 500,000 shots

-

Cavity:

-

Multi Cavity

-

Packing method:

-

Film and Wooden case

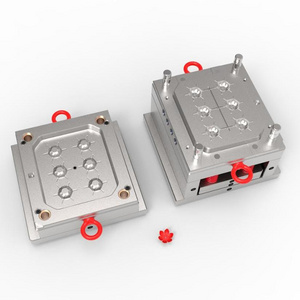

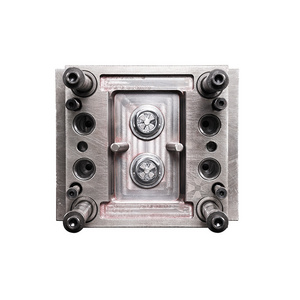

Product Intruduction

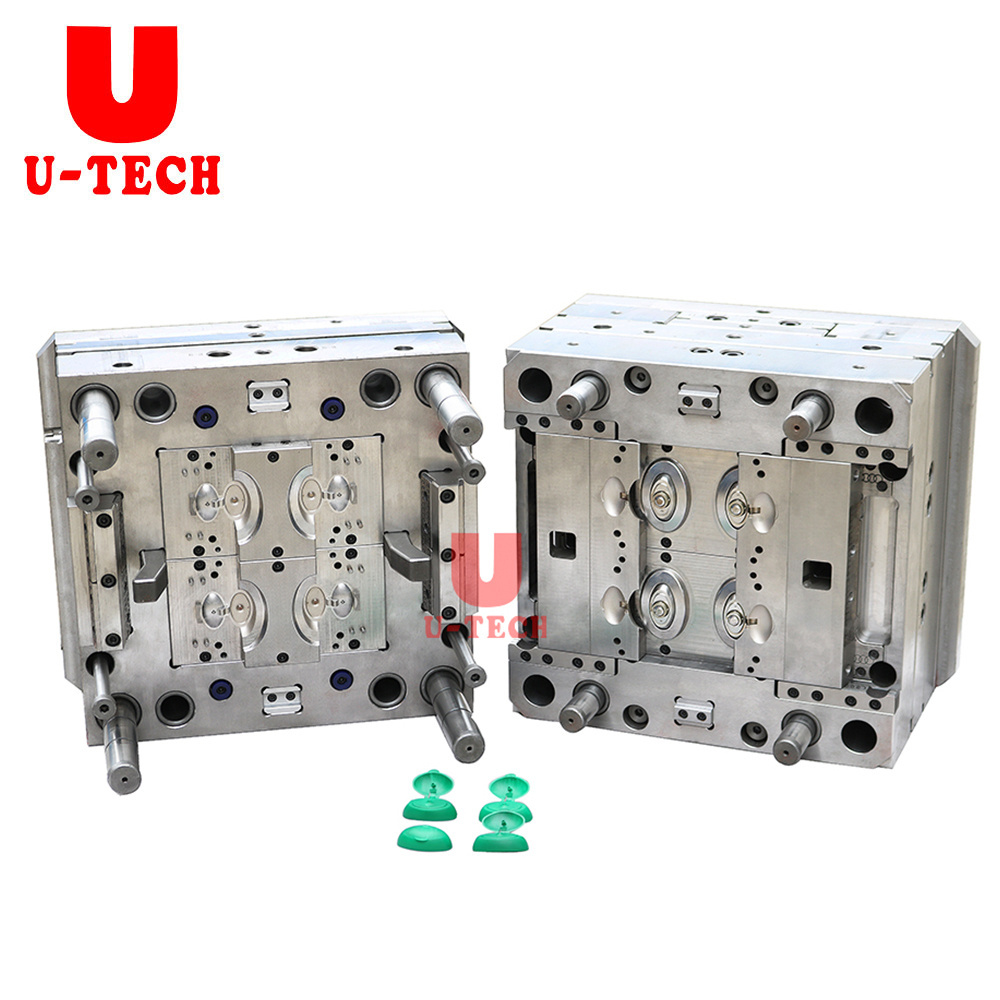

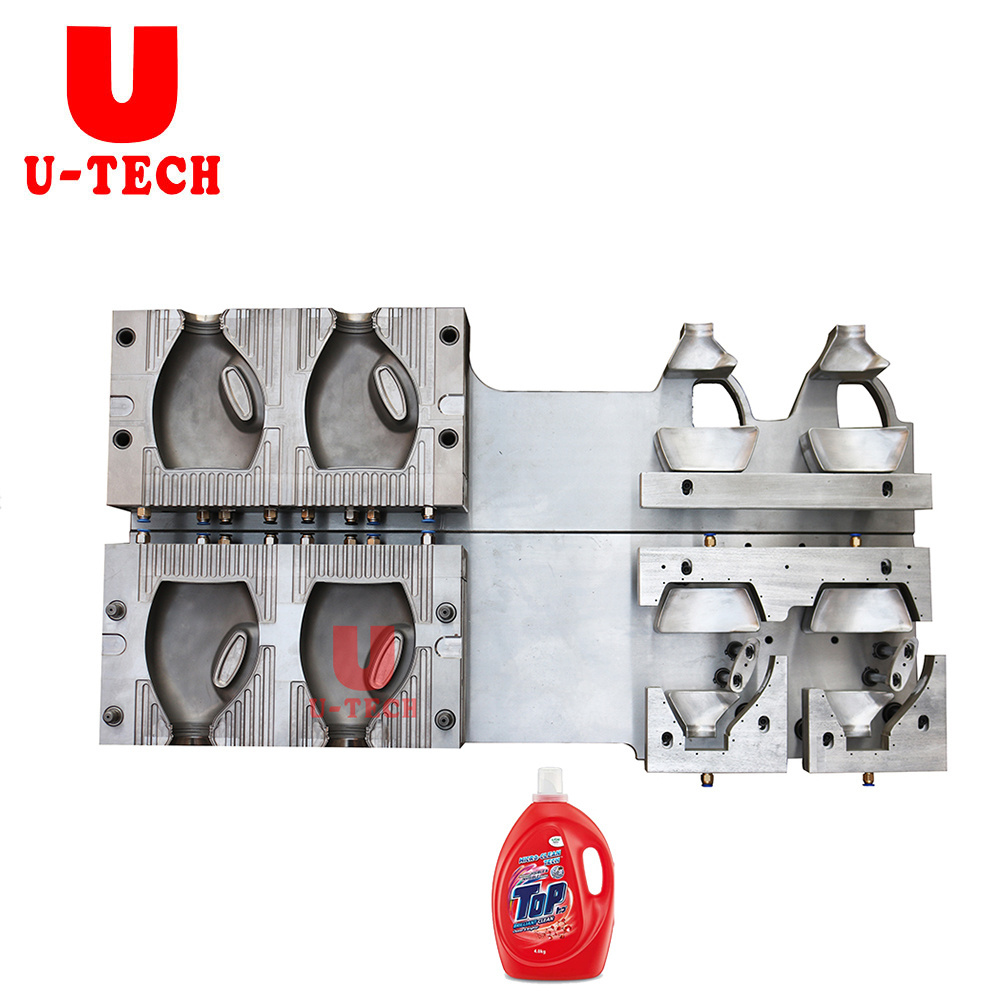

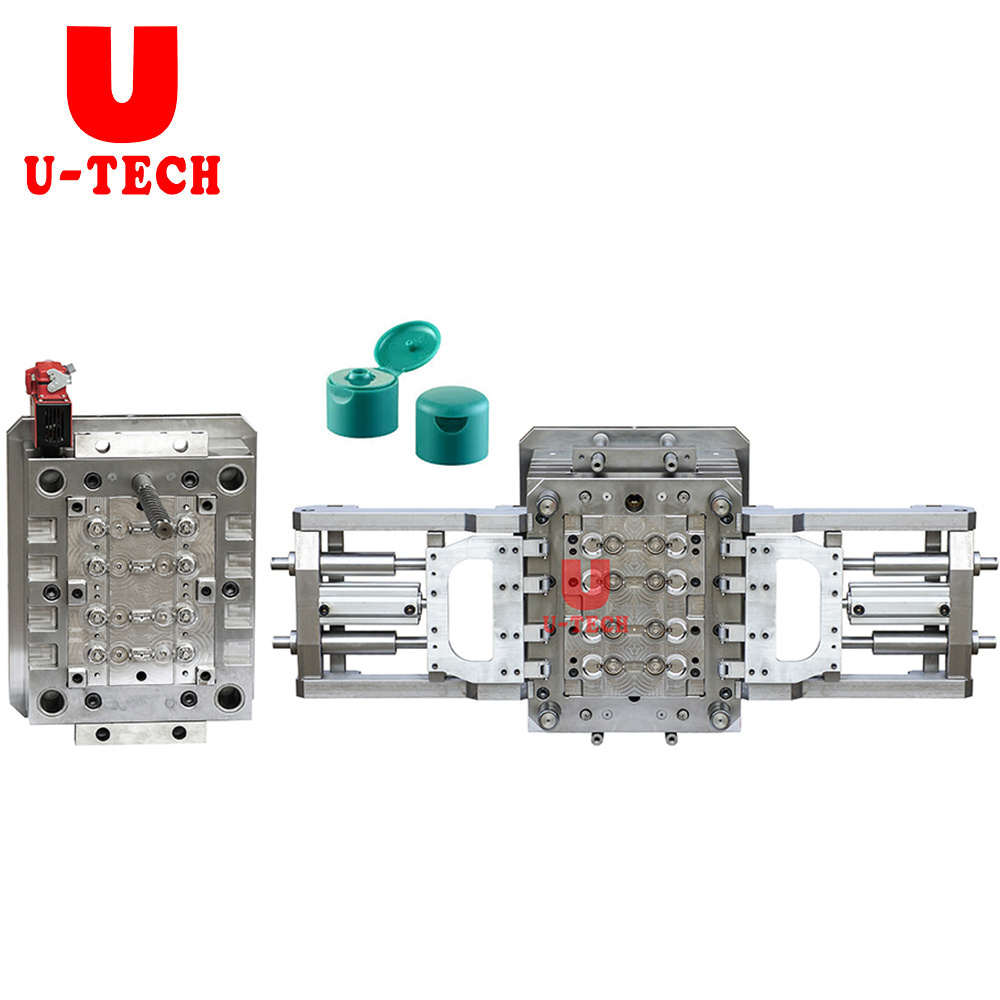

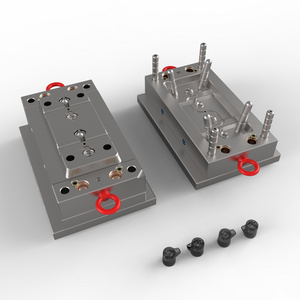

Plastic blow Mould

The rigidity, orientation, discharging mechanism, positioning method, gap size and other factors should be considered in the design and parameter selection of die structure. The wearing parts on the mold should be easy to replace. For plastic mold and die casting die, reasonable gating system, flow state of molten plastic or metal, position and direction of entering the cavity should also be considered. The first mock exam is to increase the productivity and reduce the runner loss. A number of identical or different products can be completed in one mold at the same time. High efficiency, high precision and long life mold should be used in mass production.

Product Paramenters

|

Technique

|

Plastic blow Mould

|

|

Surface treatment

|

Polishing, or as customer's requirements

|

|

Material

|

Mold: 718H, S136H, NAK80, DIN1.2344, LKM2083, LKM2344, 8406, 8407, S136, LKM2767 etc.

Product: PP, PC, PS, PE, PU, PVC, ABS, PMMA etc |

|

General size

|

According to your 3d drawings

|

|

Design software

|

UG, PROE, CAD, CAXA etc

|

|

Plastic mould life

|

500,000 shots

|

|

Manufacturing Machines

|

CNC,EDM,MILLING,WIRE-CUT, etc

|

|

Runner

|

Cold runner

|

|

Design Software

|

UG,PROE,CAD,Solidworks, etc

|

|

Cavity number of mould

|

Single cavity,Multiple cavity or one mold with different products

|

|

Surface treatment

|

Words corrosion,Mirror polish,Frosted surface or textured surface

|

|

Mould standard

|

Domestic standard, HASCO standard, DME standard. Master flow standard

|

|

Mould testing

|

All of the moulds can be well tested befre the shipments.

|

|

Good packages

|

In strong wooden pallets to avoid any damages during the long transportation

|

Flow chart

Preforms

stretch blow mold

extrusion blow mold

injection blow mold

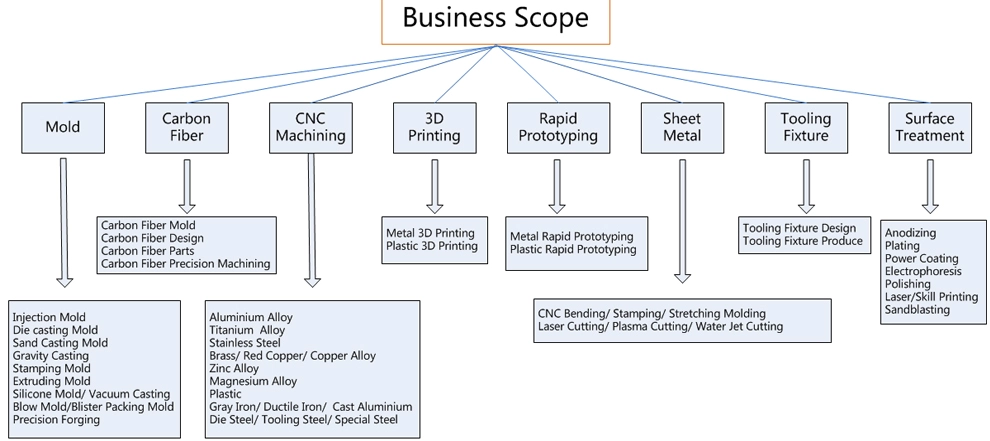

Why Choose Us

Certificate

FAQ

Q1:Do you have any reference project?

>> A1:We have reference project in most countries, and you can visit their factories if we get the permission of the customer.

Q2:What's your guarantee or the warranty of the quality if we buy your machines?

>>A2:We offer you high quality machines with 2 years guarantee . we will give u spare part free in 2 years.

Q3: Do you provide customized service?

>> A3: We will customize the machine according to your needs, materil ,power,filling type,the kinds of the bottles and so on.

Q4:When can I get my machine after I paid?

>> A4:We will deliver the machines on time as the date we agreed both side.

Q5:How can I install my machine when it arrives?

>> A5:We will send our engineer to your side as soon as you get all your machines ready , for testing and teaching your technicians how to run the machines.

Hot Searches