Conveyor system

Long service life

manual or automatic control

● Rollers in the blasting cabinet are protected by special alloy jacket with lifetime over 4,000 hours.

● Conveyor system is driven by motors with inverter. Rollers can be controlled manually and automatically.

- Product Details

- {{item.text}}

Quick Details

-

Power:

-

Cusomized

-

Dimension(L*W*H):

-

Customer's Requirement

-

Type:

-

Hook shot blasting machine for sale in China

-

Name:

-

Aluminum Alloy Car Wheel Rims Double Hook Shot Blasting Machine

-

Function:

-

Metal Rust Surface Cleaning

-

Professional Design:

-

Good Service

-

Cleaning Material:

-

Steel Structure

-

Application:

-

Casting

Quick Details

-

Place of Origin:

-

Shandong, China

-

Brand Name:

-

XITIE

-

Weight (KG):

-

25000 KG

-

Power:

-

Cusomized

-

Dimension(L*W*H):

-

Customer's Requirement

-

Type:

-

Hook shot blasting machine for sale in China

-

Name:

-

Aluminum Alloy Car Wheel Rims Double Hook Shot Blasting Machine

-

Function:

-

Metal Rust Surface Cleaning

-

Professional Design:

-

Good Service

-

Cleaning Material:

-

Steel Structure

-

Application:

-

Casting

Product Overview

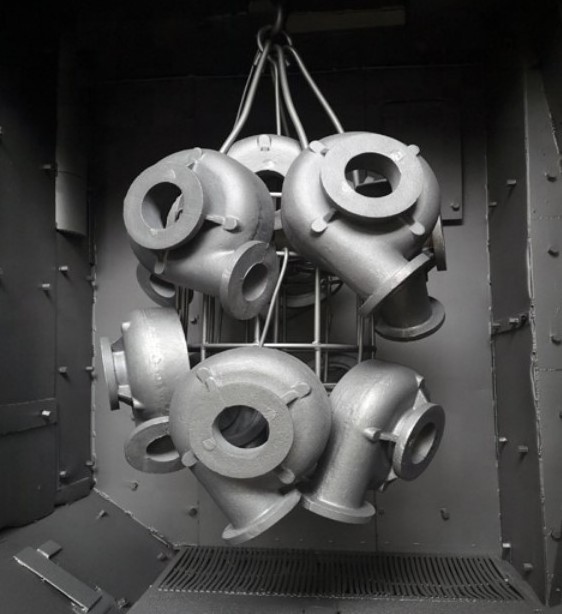

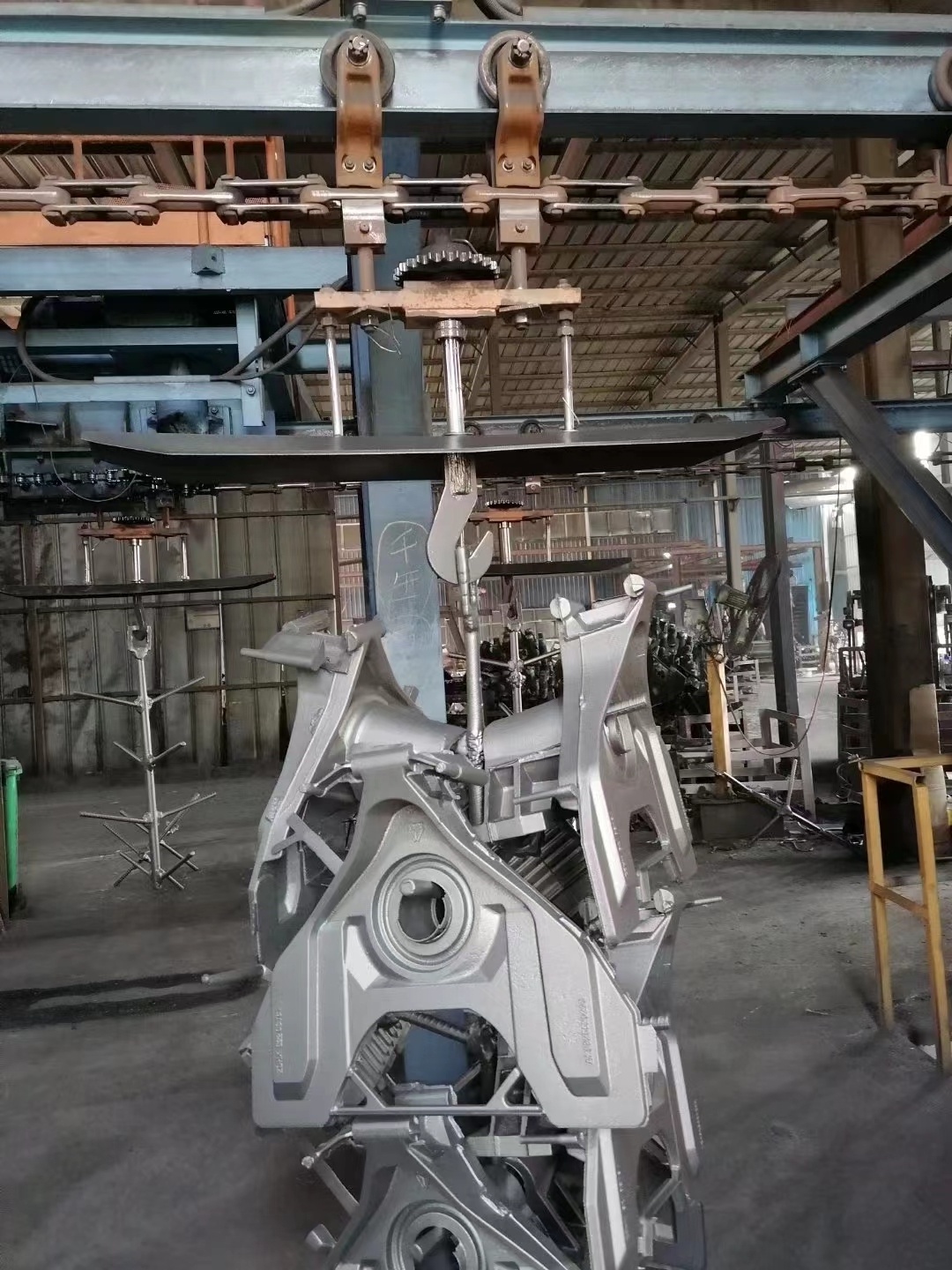

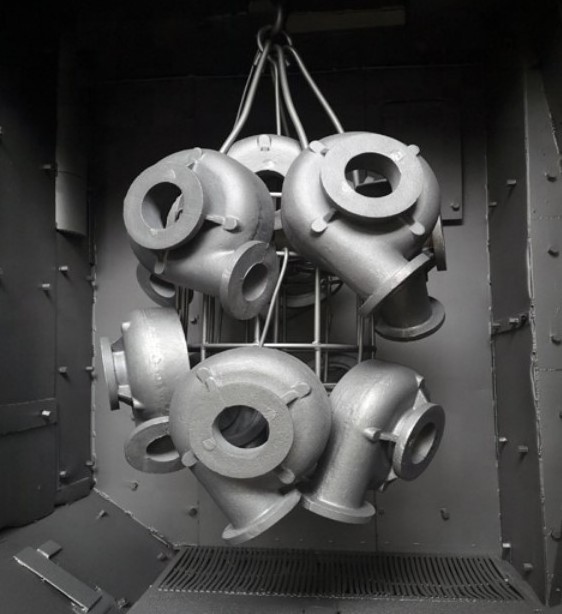

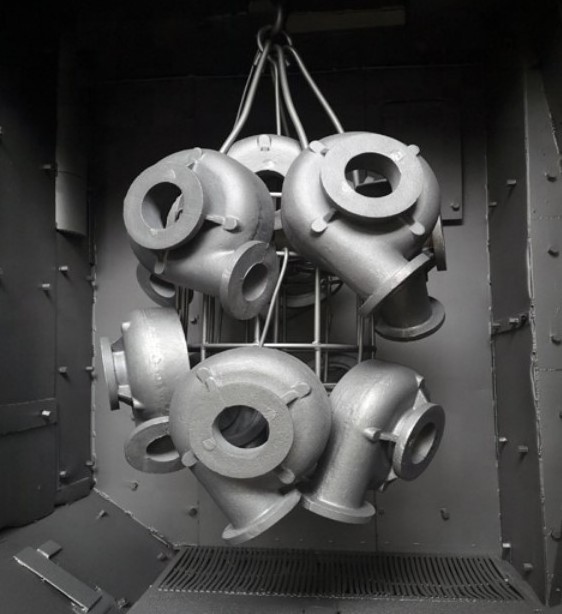

Aluminum Alloy Car Wheel Rims Derusting Double Hook Orbital Shot Blasting Machine

Monorail conveyor (hanging chain) shot blasting machine is suitable for shot blast cleaning of mass production of small and medium-sized iron castings, steel casting, forging and stamping workpiece, particularly suitable for forging, casting workpiece cleaning, to remove the adhering sand, rust, scale, dirt of workpiece surface, make the workpiece presents clean surface, eliminate the internal stress of workpiece, improve the fatigue resistance, increase the workpiece pai ting adhesion, and eventually to improve workpiece surface and inner quality.As a rule, overhead rail shot blasting machine is offered either for

batch and continuous processing.

batch and continuous processing.

PRODUCT SPECIFICATIONS

|

Type

|

Workpiece cleaning volume(mm)

|

Abrassive flow rate (kg/min)

|

|

Q383

|

Φ 600 x 1400

|

4 x 260

|

|

Q384

|

Φ 800 x 1500

|

6 x 260

|

|

Q385

|

Φ 900 x 1400

|

4 x 260

|

|

Q4810

|

Φ 1000 x 1500

|

6 x 260

|

Products Description

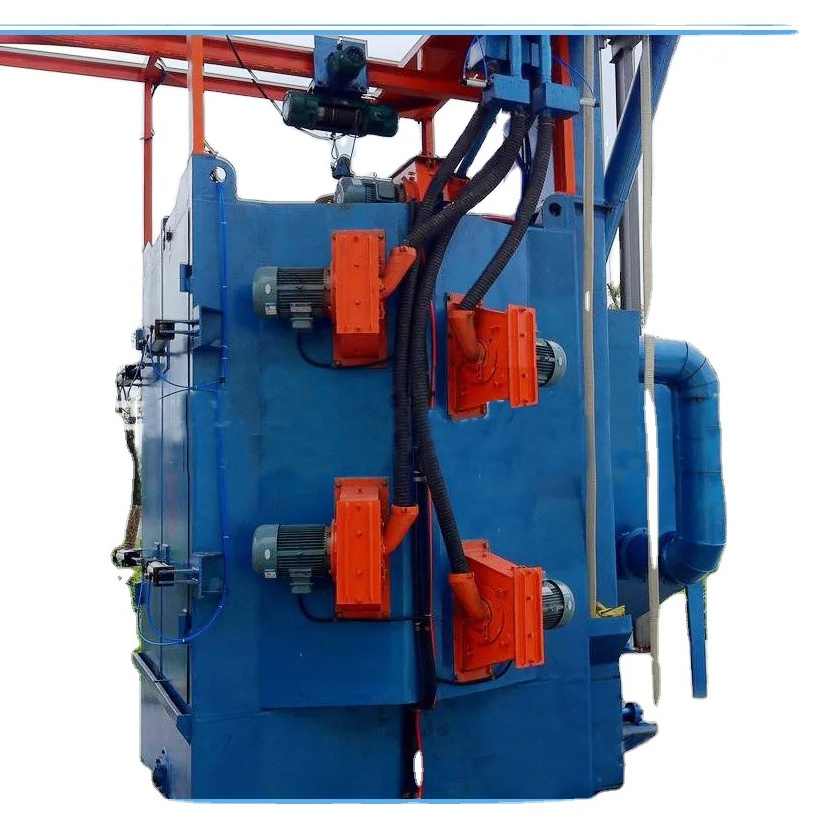

Blasting Chamber

Composition: Main blasting chamber, 2 auxiliary blasting chambers.

Auxiliary Blasting Chamber:Four layers rubber curtains

Main Blasting Chamber: blasting wheels are mounted on chamber in different angles

Divided & Modular Chambers: Designed accordingly

In the blasting chamber, the wall is protected by SPMn13 material liner and 65Mn protective liner, easy tear open outfit

replacement.

Auxiliary Blasting Chamber:Four layers rubber curtains

Main Blasting Chamber: blasting wheels are mounted on chamber in different angles

Divided & Modular Chambers: Designed accordingly

In the blasting chamber, the wall is protected by SPMn13 material liner and 65Mn protective liner, easy tear open outfit

replacement.

Abrasive Recycling System

Longitude Screw: collect abrasive at the bottom.

Horizontal Screw: Delivery abrasive from longitude screw to bucket elevator.

Bucket Elevator:Lift abrasive to separator.

Separator:Separate & get qualified abrasive

Horizontal Screw: Delivery abrasive from longitude screw to bucket elevator.

Bucket Elevator:Lift abrasive to separator.

Separator:Separate & get qualified abrasive

Product packaging

Hot Searches