- Product Details

- {{item.text}}

Quick Details

-

Brand Name:

-

Chijiang

-

Product name:

-

Polyamide 6/66 Nylon6/66 Pa6/66

-

Brand:

-

CHIJIANG

-

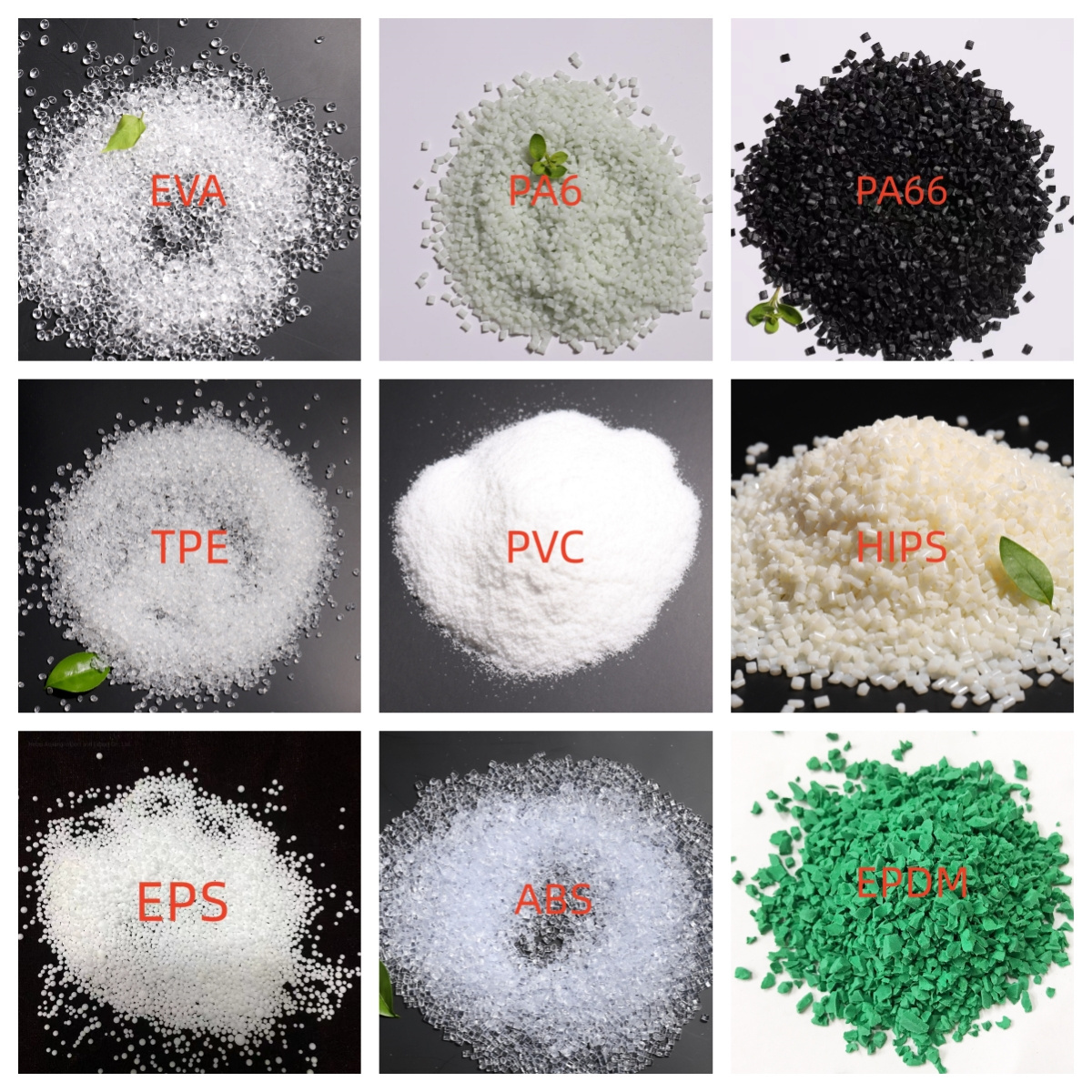

Appearance:

-

pellets or granules

-

MOQ:

-

1Ton

-

HS code:

-

3908101200

-

Sample:

-

Avialable

-

Package:

-

25KG/BAG

-

Processing:

-

Injection Molding Grade

-

Material:

-

PA Raw Material Granule

Quick Details

-

color:

-

nature

-

Shape:

-

Granules

-

Place of Origin:

-

Hebei, China

-

Brand Name:

-

Chijiang

-

Product name:

-

Polyamide 6/66 Nylon6/66 Pa6/66

-

Brand:

-

CHIJIANG

-

Appearance:

-

pellets or granules

-

MOQ:

-

1Ton

-

HS code:

-

3908101200

-

Sample:

-

Avialable

-

Package:

-

25KG/BAG

-

Processing:

-

Injection Molding Grade

-

Material:

-

PA Raw Material Granule

Products Description

PA6 Basic parameters

PA6, also known as nylon 6, is a translucent or opaque milky white particle. It is generally used in auto parts, mechanical parts,electrical and electronic products, engineering accessories, etc. . Basic parameters: Name: Polyamide 6 or Nylon 6 (PA6)

Properties: Translucent or opaque milky white crystalline polymer Properties: thermoplastic, lightweight, tough, chemical

resistance and durability Burning identification method: yellow flame on blue background, burning vegetable flavor Solvent test:resistance to cyclohexanone and aromatic solvents Density: (g/cm3) 1.14-1.15 Balanced water absorption: 3.5% Has good wear resistance, self-lubrication and solvent resistance. Tensile strength:> 60.0Mpa Elongation:> 30% Bending strength: 90.0Mpa

PA6 characteristic

The chemical and physical properties of PA6 are very similar to PA66, however, it has a lower melting point and a wide process,temperature range, using PA6. In order to improve the mechanical properties of PA6, various modifiers are often added. Glass fiber is the most common additive, and sometimes synthetic rubbers such as EPDM and SBR are added to improve impact resistance. For products without additives, the shrinkage of PA6 is between 1% and 1.5%. Adding glass fiber additives can reduce the shrinkage to 0.3% (but slightly higher in the direction perpendicular to the process). The shrinkage of the molding assembly is mainly affected by the crystallinity and hygroscopicity of the material. Actual shrinkage is also a function of part design, wall thickness and other process parameters.

Properties: Translucent or opaque milky white crystalline polymer Properties: thermoplastic, lightweight, tough, chemical

resistance and durability Burning identification method: yellow flame on blue background, burning vegetable flavor Solvent test:resistance to cyclohexanone and aromatic solvents Density: (g/cm3) 1.14-1.15 Balanced water absorption: 3.5% Has good wear resistance, self-lubrication and solvent resistance. Tensile strength:> 60.0Mpa Elongation:> 30% Bending strength: 90.0Mpa

PA6 characteristic

The chemical and physical properties of PA6 are very similar to PA66, however, it has a lower melting point and a wide process,temperature range, using PA6. In order to improve the mechanical properties of PA6, various modifiers are often added. Glass fiber is the most common additive, and sometimes synthetic rubbers such as EPDM and SBR are added to improve impact resistance. For products without additives, the shrinkage of PA6 is between 1% and 1.5%. Adding glass fiber additives can reduce the shrinkage to 0.3% (but slightly higher in the direction perpendicular to the process). The shrinkage of the molding assembly is mainly affected by the crystallinity and hygroscopicity of the material. Actual shrinkage is also a function of part design, wall thickness and other process parameters.

Specification

PA6 Chip 275 TDS:

|

Features

|

Medium Viscosity, Bright chips, General grade, Insulation, wear-resisting, electric corrosion-resisting, alkali resistance

|

|

|

||

|

Process Method

|

Injection Molding

|

|

|

||

|

Application

|

Spinning, fishing nets, conventional spinning, modified plastic material

|

|

|

||

|

Physical Properties

|

Test Method

|

Unit

|

Value

|

||

|

Density

|

ISO 1183

|

g/cm³

|

1.122

|

||

|

Melt Flow Rate

|

ISO 1133

|

g/10min

|

20.6

|

||

|

Relative Viscosity

|

INTERNAL METHOD

|

%

|

2.78 (2.75±0.03)

|

||

|

Moisture Content

|

ISO 62

|

%

|

3.37

|

||

|

Particle content with black dots

|

INTERNAL METHOD

|

particles/100g

|

< 1

|

||

|

Shrinkage

|

GB/T 17037.4

|

%

|

0.53~0.61

|

||

|

Mechanical Properties

|

Test Method

|

Unit

|

Value

|

||

|

Tensile strength yield

|

ISO 527

|

MPa

|

65.3

|

||

|

Tensile strength break

|

ISO 527

|

MPa

|

39.5

|

||

|

Tensile modulus

|

ISO 527

|

MPa

|

2321

|

||

|

Elongation Yield

|

ISO 527

|

%

|

1.6

|

||

|

Elongation Break

|

ISO 527

|

%

|

113

|

||

|

Tensile break nominal strain

|

ISO 527

|

%

|

164

|

||

|

Impact Properties

|

Test Method

|

Unit

|

Value

|

||

|

Charpy Notched Impact Strength

|

ISO 179

|

KJ/m²

|

3.7

|

||

|

Thermal Properties

|

Test Method

|

Unit

|

Value

|

||

|

HDT temperature

|

ISO 75-2

|

℃

|

50

|

||

|

Melt Temperature

|

ISO 11357-3

|

℃

|

222.3

|

||

|

Electrical Properties

|

Test Method

|

Unit

|

Value

|

||

|

Surface Resistivity

|

IEC 60093

|

ohms

|

5.3*10^14

|

||

|

Volume Resistivity (23℃)

|

IEC 60093

|

ohms·m

|

6.0*10^11

|

||

|

Dielectric Constant

|

IEC60250

|

F/m

|

3.32

|

||

|

Dielectric Loss Angle Tangent

|

IEC 60250

|

MHZ

|

2.0*10^-2

|

||

Prouduct Application

PA6 has thermoplastic properties, in light weight, good, toughness, chemical resistance and durability. it is widely used in the manufacture of bearings, circular gears, cams, bevel gears, various rollers, pulleys, pump impellers, fan blades, worm gears, propellers, screws, nuts, gaskets, high-pressure sealing rings, oil-resistant sealing gaskets , oil-resistant containers,

housings, hoses, cable jackets, shears, pulley sleeves, planer sliders, solenoid distribution valve seats, cold aging equipment,gaskets, bearing cages, various oil pipes on automobiles and tractors, pistons , ropes, transmission belts, zero fog materials for textile machinery and industrial equipment, as well as daily necessities and packaging films.

housings, hoses, cable jackets, shears, pulley sleeves, planer sliders, solenoid distribution valve seats, cold aging equipment,gaskets, bearing cages, various oil pipes on automobiles and tractors, pistons , ropes, transmission belts, zero fog materials for textile machinery and industrial equipment, as well as daily necessities and packaging films.

Packing & Delivery

1.Packing:

25kg/bag,50kg/ bag or per your requirement.

18mt/20'FCL,26mt/20'FCL

2.Storage:

The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the

open air.

3.Transportation:

25kg/bag,50kg/ bag or per your requirement.

18mt/20'FCL,26mt/20'FCL

2.Storage:

The resin should be stored in a drafty, dry warehouse and away from fire and direct sunlight. It should not be piled up in the

open air.

3.Transportation:

During transportation, the product should not be exposed to strong sunlight or rain and should not be transported

together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is

strictly prohibited.

together with sand, soil, scrap metal, coal or glass. Transportation together with toxic, corrosive and flammable substance is

strictly prohibited.

Hot Searches