- Product Details

- {{item.text}}

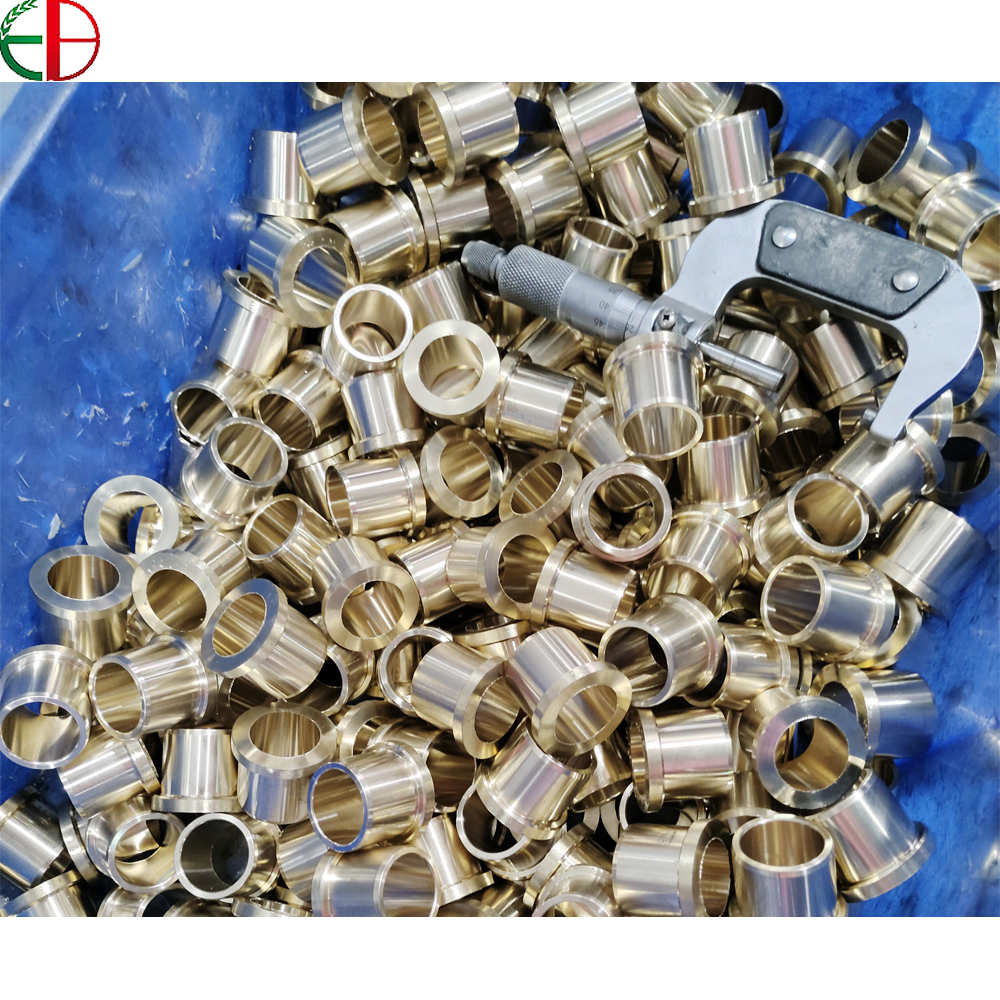

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

EB

-

Model Number:

-

EB1232

-

Process:

-

Casting/CNC Machining

-

Color:

-

Customized Color

-

Features:

-

High load capability,Low weight , Good corrosion resistance.

-

Other Type:

-

Flange ,Washer

-

Lubrication:

-

Oil Lubrication

Quick Details

-

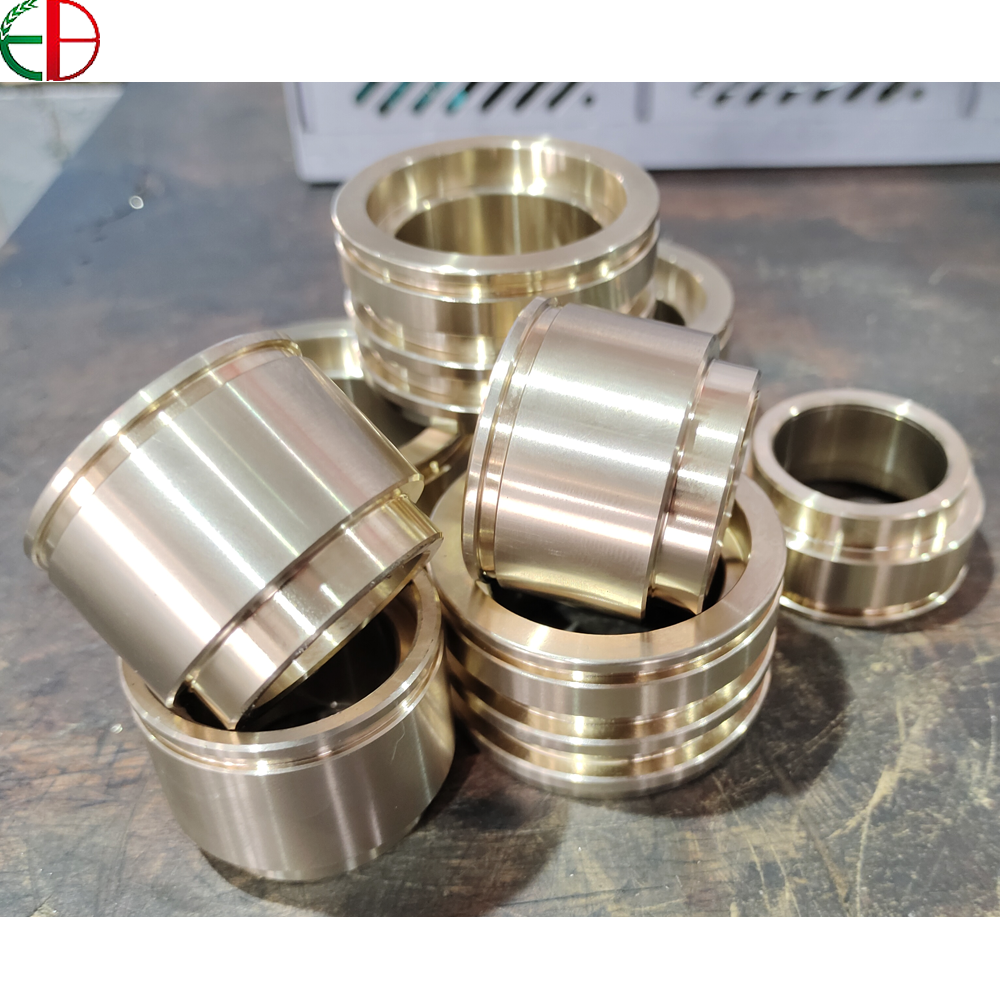

Applicable Industries:

-

Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Energy & Mining

-

Type:

-

bushing

-

Material:

-

Brass, CuZn25Al5Mn4Fe3/CuSn8P

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

EB

-

Model Number:

-

EB1232

-

Process:

-

Casting/CNC Machining

-

Color:

-

Customized Color

-

Features:

-

High load capability,Low weight , Good corrosion resistance.

-

Other Type:

-

Flange ,Washer

-

Lubrication:

-

Oil Lubrication

Product Description

|

|

QAL9-2

|

It has high strength and wear-reducing properties. It can be welded but not easy to braze. It is widely used in mechanical and electrical appliances and wear-resistant and corrosion-resistant parts.

|

|

|

QAL9-4(C61900)

|

|

|

|

QAL10-3-1.5

|

|

|

|

QAL10-4-4(C6301)

|

|

|

|

QAL10-5-5

|

|

|

|

C64200(USA)

|

|

|

Phosphor bronze/

Tin Phosphor bronze

|

ZQSn5-5-5

|

|

|

|

ZQSn10-1

|

|

|

|

ZQSnD6-6-3

|

|

|

|

QSn6.5-0.1(C5191)

|

|

|

|

QSn6.5-0.4

|

|

|

|

QSn7.0-0.2(C5210)

|

|

|

|

QSn4-3

|

|

|

|

QSn4-0.3(CuSn4)

|

|

|

|

QSn8-0.3(CuSn8, C5212)

|

|

|

|

QSi1-3

|

It has high strength and wear resistance, high corrosion resistance, weldability and machinability.

|

|

|

Qsi3-1

|

|

|

|

|

Requires high conductivity, high conductivity and corrosion resistance.

|

Features:

Bronze with tin as the main alloying element. The tin content is generally between 3 and 14%, and is mainly used to make elastic components and wear-resistant parts. The tin content of deformed tin bronze does not exceed 8%, and sometimes phosphorus, lead, zinc and other elements are added. Phosphorus is a good deoxidizer and also improves flow and wear resistance. Adding lead to tin bronze can improve machinability and wear resistance, and adding zinc can improve casting properties. This alloy has high mechanical properties, anti-wear properties and corrosion resistance, is easy to cut and process, has good brazing and welding properties, has a small shrinkage coefficient and is non-magnetic. Coatings such as bronze bushings, bushings, and antimagnetic components can be prepared by wire flame spraying and arc spraying.

Tin Bronze/5 Common Grades:

1.QSN4-3, corrosion-resistant and wear-resistant parts, antimagnetic components and springs, etc.

2.QSN4-4-2.5, parts subject to friction, such as bushings, bearings, discs, etc.

3.QSN6.5-0.1, spring contact piece, wear-resistant and anti-magnetic parts in precision instruments.

4.QSN6.5-0.4, used for papermaking copper mesh, springs, wear-resistant parts, etc.

5.QSN7-0.2, used for workpieces that are subject to friction, such as bearings, worm gears and springs.

Aluminum Bronze/5 Common Grades:

1.QAI5, used for corrosion-resistant elastic components.

2.QAI9-2, pipe fittings working in steam below 250℃.

3.QAI9-4, used for bearings, gears, valve seats, ship parts and electrical components.

4.QAI7, used for gears, friction wheels, worm gear transmission mechanisms, etc.

5.QAl10-3-1.5, used for wear-resistant parts working at high temperatures, such as bearings, gears, flywheels, etc.

Silicon Bronze/2 Common Grades:

1.QSI1-3 is used for friction parts working below 300℃, such as intake and exhaust valve guide bushes.

2. QSI3-1, used for springs, worm gears, worm gears and corrosion-resistant parts, etc.

Why Choose Us

Q: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5~10 days if the goods are in stock.Or it is 45 days if the goods are not in stock, it is according to

quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shipment. irrevocable LC at sight.

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5~10 days if the goods are in stock.Or it is 45 days if the goods are not in stock, it is according to

quantity.

Q: What is your terms of payment ?

A: Payment<=1000USD, 100% in advance. Payment>=1000USD, 50% T/T in advance ,balance before shipment. irrevocable LC at sight.

Hot Searches