- Product Details

- {{item.text}}

Quick Details

-

Power:

-

100w

-

Dimension(L*W*H):

-

customized

-

Weight:

-

300 kg

-

Filter degree:

-

80-500 Microns

-

Flow rate:

-

15-900T/H

-

Application:

-

cooling tower,air conditioning,heat exchange,irrigation,lake,sea

-

Chamber material:

-

Carbon steel or stainless steel

-

Install direction:

-

vertical or horizontal

-

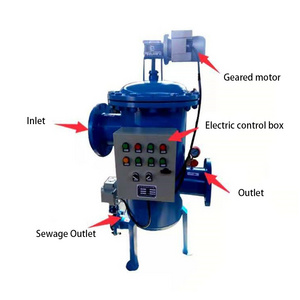

Control method:

-

Differential pressure, time and manual

-

Backwash time:

-

50-90S

-

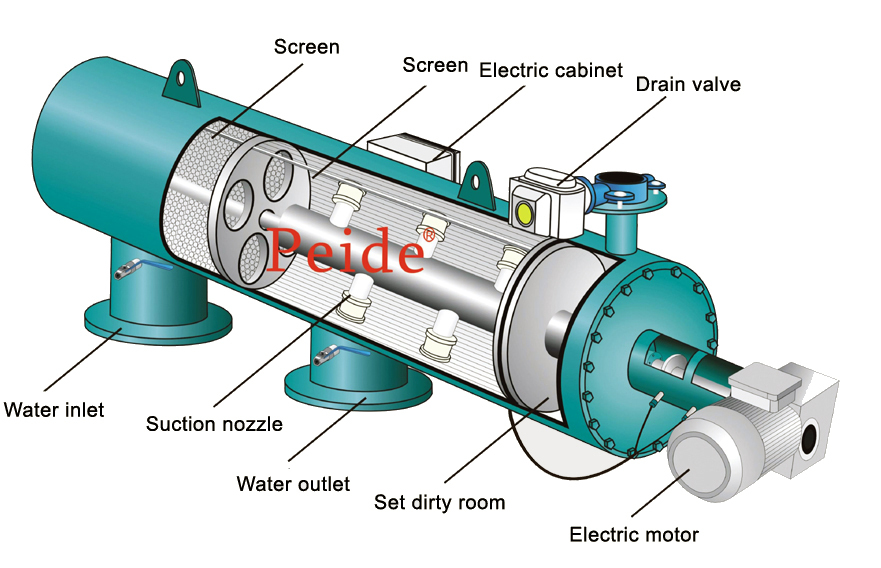

Screen:

-

Multi stainless steel mesh + pvc structure

-

Max working pressure:

-

1.0Mpa,1.6Mpa

Quick Details

-

Place of Origin:

-

Jiangsu, China

-

Brand Name:

-

Peide

-

Voltage:

-

220V/380V/Others, AC220V 380V,50Hz,3PH,CONTROLLER:220V

-

Power:

-

100w

-

Dimension(L*W*H):

-

customized

-

Weight:

-

300 kg

-

Filter degree:

-

80-500 Microns

-

Flow rate:

-

15-900T/H

-

Application:

-

cooling tower,air conditioning,heat exchange,irrigation,lake,sea

-

Chamber material:

-

Carbon steel or stainless steel

-

Install direction:

-

vertical or horizontal

-

Control method:

-

Differential pressure, time and manual

-

Backwash time:

-

50-90S

-

Screen:

-

Multi stainless steel mesh + pvc structure

-

Max working pressure:

-

1.0Mpa,1.6Mpa

Product Paramenters

|

Standard Design Pressure

|

10/16/25bar

|

|

Mini. Working Pressure

|

3bar (depend on the viscosity and filtration degree)

|

|

Flow rate Range

|

25~3000m³/h

|

|

Applicable Liquid

|

Viscous Liquid

|

|

Back-flushing Liquid

|

Filtered Clean Water

|

|

Filtration Degree

|

100-1000μm

|

|

Working Principle

|

Single Filter Continuous Filtration, Automatic Back-flushing

|

|

Design Temperature

|

0-120℃

|

|

Back-flushing Cycle

|

Differential Pressure and Time

|

|

Differential Pressure Instrument

|

Intelligent Differential Pressure Transmitter/switch

|

|

Inlet and Outlet Standard

|

ANSI Flange CLASS150/DIN Flange PN10/ Sanitary Coupling

|

|

Housing Wet Part Material

|

CS/304/316L

|

|

Filter Screen Material

|

304/316L

|

|

Sealing Material

|

NBR/EPDM/VITON/Silastic

|

|

Back-flushing Valve

|

Pneumatic Ball Valve/ Electric Butterfly Valve

|

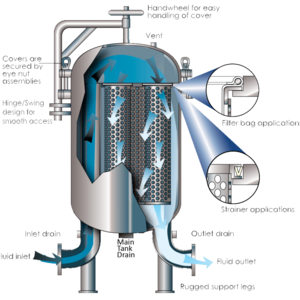

The unit consists of two stages of filtration, a coarse pre-filter and a stainless steel fine screen. The unwanted solids accumulate on the inner surface of the fine screen, building up a filter cake, which filters out even finer particles, creating a pressure differential. Once the pressure drop reaches a preset level, a rinse cycle is activated by the factory supplied control system. The solids are removed from the fine screen using a spot backwashing method, which aggressively sucks the dirt off the screen,similar to a vacuum cleaner, and are carried to the drain via the rinse valve. The dirt collector rotates, ensuring the entire,screen is cleaned each cycle. The process takes a matter of seconds, without interruption of system flow.

Product Advantages

Two layer screen,which not only remove large solids but also small suspended solids

Vertical type and Horizontal type easy to install according to site pipe line.

|

Model

|

Pipe

|

T/H

|

Filter

area(cm 2 ) |

Drain(mm)

|

Water

consumption (L) |

motor(KW)

|

weight(Kg)

|

|

XLQ-200XT

|

200

|

300

|

7500

|

50

|

250

|

0.55

|

340

|

|

XLQ-250XT

|

250

|

450

|

11000

|

80

|

400

|

0.55

|

350

|

|

XLQ-300XT

|

300

|

650

|

11000

|

80

|

400

|

0.55

|

365

|

|

XLQ-350XT

|

350

|

900

|

13800

|

80

|

400

|

0.55

|

630

|

|

XLQ-400XT

|

400

|

1200

|

13800

|

80

|

400

|

0.55

|

650

|

|

XLQ-350XT

|

350

|

1500

|

13800

|

80

|

400

|

0.55

|

690

|

Details Images

Company Exhibition

We actively participate in the organization of exhibitions and actively cooperate with partners from various countries to promote economic development.

1. Q: What terms of payment do you accept?

A: Payment method:T/T,Paypal,western union.

2. Q: What is your delivery time?

A: Delivery term:10-30 working days.

3. Q: What's the minimum quantity of your order?

A: MOQ:1 Set.

4. Q: How long is the warranty?

A: Quality guarantee period:1 year

Production Process

Hot Searches