- Product Details

- {{item.text}}

Quick Details

-

Application:

-

hand exercise , decoration ..

-

Place of Origin:

-

Guangdong, China

-

Product:

-

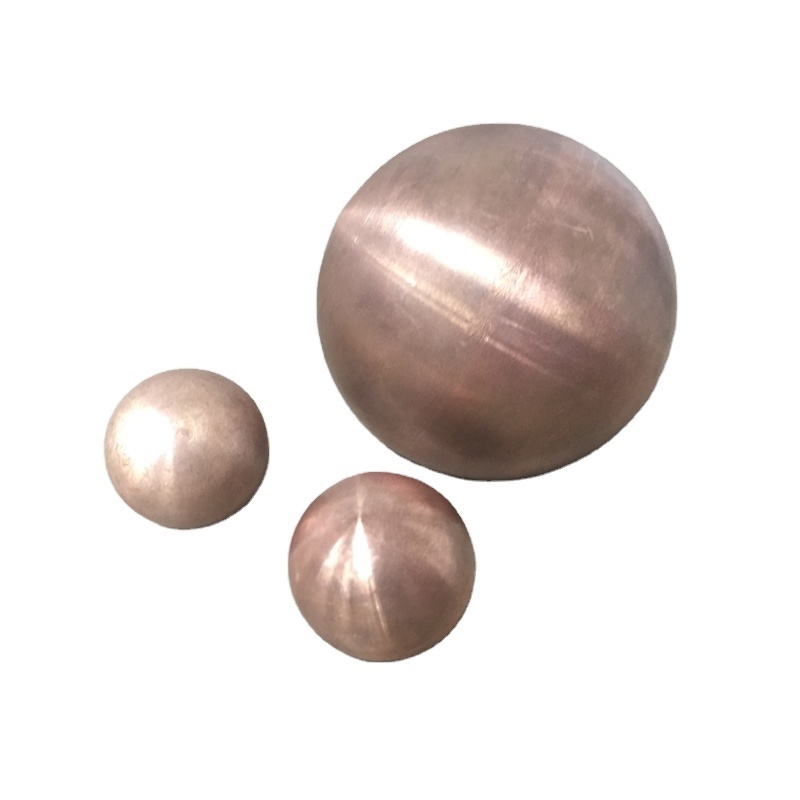

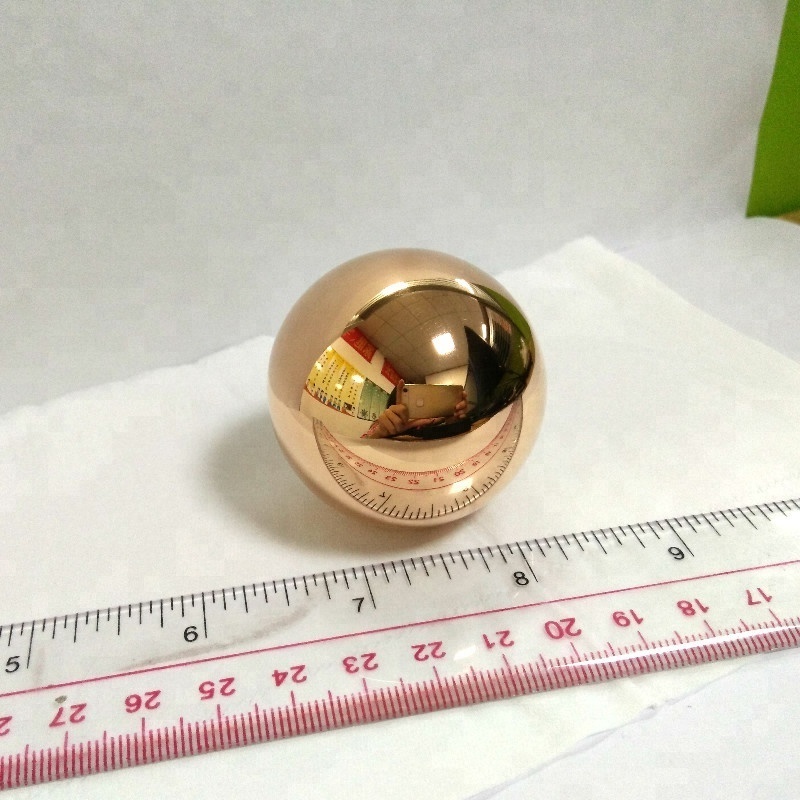

solid copper ball

-

size:

-

5cm

-

Color:

-

self-color

-

Surface treatment:

-

polishing,brushed

-

Service:

-

OEM & ODM

-

Other customized service:

-

drilled,threaded

-

Tolerance:

-

+/-0.05mm refer to the grade

-

Packing:

-

standard export packing

-

Certification:

-

SGS/ROHS

-

Shape:

-

Round Solid

Quick Details

-

Grade:

-

copper

-

Steel Grade:

-

copper

-

Surface Finish:

-

BA

-

Application:

-

hand exercise , decoration ..

-

Place of Origin:

-

Guangdong, China

-

Product:

-

solid copper ball

-

size:

-

5cm

-

Color:

-

self-color

-

Surface treatment:

-

polishing,brushed

-

Service:

-

OEM & ODM

-

Other customized service:

-

drilled,threaded

-

Tolerance:

-

+/-0.05mm refer to the grade

-

Packing:

-

standard export packing

-

Certification:

-

SGS/ROHS

-

Shape:

-

Round Solid

Customized High Quality solid 5cm 50mm copper sphere

| Brand | Shine |

| Product |

Copper Ball

|

| Place of Origin | Shandong, China (Mainland) |

| Material | C11000, T2 |

| Core | Solid |

| Shape | Round |

| Diameter | 0.3-100mm |

| Grade | G100-1000 |

| Certification | SGS, RoHS |

unpolished surface

Hand polished surface

|

characteristic

thermal and electric conductivity. Small amounts of alloying elements as Cr, Zr, Ag, Cd, Mg, Sn allow

to improve the mechanical properties.

|

|||||||

|

Chemical composition:

|

|||||||

| EN | USA | GER | FRA | UK | RUS | CHN | JAP |

| CW004A | C11000 | 2.0065 | Cu-a 1 | C101 | M0 | T2 | C 1100 |

|

Corrosion Resistance

solutions. They do not resist in contact with oxidizing acids, halogens, sulphides, ammonia, sea water. |

|||||||

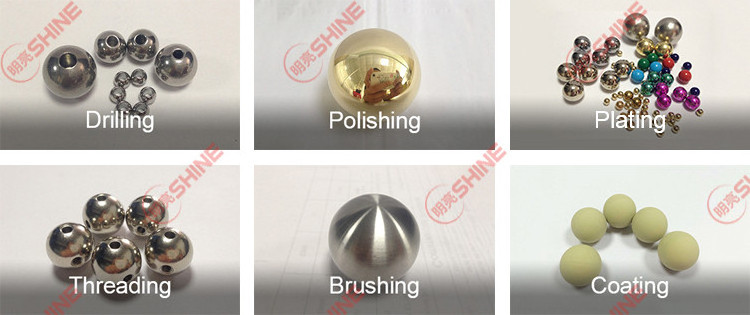

OEM

Because we're not just a ball company, we can go beyond this technology to provide subassemblies or complete solutions. We can combine our ball technology with our injection molding, segmented linear bearing, and motion control expertise. We have extensive in-house tool room capabilities and offer rapid prototyping. With manufacturing facilities that span the globe, we can produce and deliver your solution with minimum time and cost.

Distinctively Shaped Ball: We offer a variety of flat, diagonally cut, cone and pin shaped balls that are typically used as hardened polishing and shaping tools. For example, the diagonally cut and shaped balls can be used to polish surfaces with sharp angles. Flat balls are typically used to polish uniformly shaped surfaces such as soins. Sizes and materials can be made available to suit your needs. Contact us to find the product that's just right for you.

Drilled Ball: Mingliang offers a full range of sizes, hole depths (including thru-hole), diameters and materials. Typical applications include body jewelry, earring posts, rings, seal slides, valves, and automotive engine push rods.

Plated Ball: Platings are used to enhance the physical properties of precision balls. These may include added hardness (titanium nitride), corrosion resistance (molybdenum disulfide), noise supression (rubber), and electrical characteristics (gold). Mingliang offers a myriad of plating to meet your needs.

Hollow Ball: Hollow balls are typically used for weight sensitive applications such as aircraft ball transfer units, liquid float systems, and custom ball valves. We provide 201, 304, 316 stainless steel hollow balls in a variety of sizes.

Package

1. pp bag + carton

2. pp bag + carton + woven bag

3. pp bag + woven bag

Note: package can be customized

Production Flow

Heading:

A coil of wire is cut to the required length and each piece compressed and shaped into balls using a pressing machine.

Flashing:

The surface of the balls is ground to remove the bands generated in the heading process.

Heat treatment:

After the bands have been removed, the balls are quenched adn tempered to give them sufficient strength and durability.

Grinding:

In addition to removing parts decarburized in the heat treatment, this process adjusts dimensional precision and finishes the balls to the stipulated dimensional difference.

First lapping:

The dimensional precision of the balls is further improved and they are finished to the specified dimensional difference.

Second lapping:

In addition to increasing the balls' dimensional precision to grade level, this process gives the surface of the balls a smooth, glass like finish.

Visual inspection:

All of the finished steel balls and all of their surface visually inspected automatically. These visual inspection ensure that the balls supplied to customers have no flaws.

Packing:

Balls that pass visual inspection are treated with anti-corrosive oil and then packed in paperboard boxes.

Quality Assurance

After precision washing, oiling & before packing sample balls from the batch are sent for final audit to check for surface roughness, roundness, waviness, lot size variation and hardness in a sophisticated laboratory, according to specified control plans and dock audit procedures. Once all requirements are met, a test certificate is then prepared for the customer. Our sophisticated laboratory is equipped with high precision, worldwide respected machines and equipment and is managed by properly trained and qualified personnel.

Why Choose Us

1. Professional manufacturer of steel balls since 1988.

2. Non-standard sizes of steel balls supplied.

3. Special types of steel balls supplied.

4. RoHS certified by SGS, field certified by MiC.

5. Small MOQ with competitive price.

6. Fast delivery based on quality guaranteed.

7. Small quantity of free samples could be provided.

8. All inquiries and messages will be replied in 24 hours.

About Mingliang Steel Ball

Mingliang Steel Ball Factory was founded in 2000 and is well known as professional precision steel ball manufacturer in China.

The specific power of Mingliang is the wide range of sizes, metal materials and grades completely available in one source of supply.

Mingliang is employing 18 people in Guangzhou marketing office and the Shandong facility is employing 88 people and covers 6,000 square meters including headquarters, workshop, warehouse, quality control department.

The QC Dept is equipped with high tech control machines testing all technical features of each batch products.

Our warehouse is constantly filled with more than 3000tons of finished goods in order to satisfy in the shortest terms the requirements of our customers.

Mingliang's goal is to guarantee all our customers with the most appropriate goods in best price.

Welcome to visit Mingliang at your convenience.

How to Inquire

When ordering balls, please specify the following:

1. Nominal ball diameter.

2. Type of material.

3. Precision grade.

All standard balls are always in stock and ready for immediate off-the-shelf delivery. If your application calls for custom balls, send us your specifications and we'll gladly meet them.